UF Membrane

Ultrafiltration Membrane (UF)

Water Treatment System & Membrane Selection and Ordering Can Be Easy & Safe

Whether you are replacing an old project or designing a new project, we can provide it for you based on our rich experience. We have professional sales staff to connect with you to solve all your problems from purchasing to using the membrane element.

Ultrafiltration Membrane (UF)

Ultrafiltration (UF) is a separation principle for screening, with pressure as the driving force to realize mechanical separation membrane separation process , namely under certain pressure , when the mixed solution of large molecules or a small molecule solute through the membrane surface, solvent (e.g., inorganic salt) and small molecule solutes through the membrane, and the solute molecules due to mechanical filtration membrane as concentrate intercept. To achieve the purpose of purification, separation and concentration.

Hollow fiber ultrafiltration membrane is an important form of separation membrane . The membrane pores are capillary , and the micropores are located on the wall of the tube. The solution is based on whether its components can be purified, separated and concentrated through these micropores.Among the membrane components per unit volume, hollow fiber membrane has the largest effective area , high filtration and separation efficiency , easy cleaning , simple structure , easy operation and low price .The production process does not produce secondary pollution, so it is widely used.

Operating Parameters

| Material | PES | PVDF | PAN | |

| Module | (Inside-out) | (Inside-out) | (Outside-in) | (Inside-out) |

| Membrane diameter ID/OD(mm) | 1.0/1.6 | 0.7/1.3 | 0.7/1.3 | 1.4/2.2 |

| Maximum Feed turbidity | <50NTU | <100NTU | <80NTU | |

| Maximum chlorine resistance | continuously 50ppm Instantaneously 500ppm |

continuously 200ppm Instantaneously 2000ppm |

continuously 5ppm Instantaneously 100ppm |

|

| Temperature range | 2-10 | 2-12 | 2-10 | |

| PH range | 5-45 ℃ | |||

| Operation module | Cross flow or dead-end | |||

| Maximum permeate Flux | 120L/m²·h | 150L/m²·h | 150L/m²·h | |

| Maximum Feed pressure | 0.5 MPa | |||

| Maximum trans membrane pressure | 0.2 MPa | |||

| Maximum Back wash pressure | 0.25 MPa | |||

| Back wash frequency | 15-60 min | |||

| Back wash duration | 30-60 sec | |||

| Back wash flux | 100-360 L/m²·h | |||

| Chemical enhanced backwash (CEB) frequency | 1-15 day | |||

| Chemical enhanced backwash (CEB) duration | 1-10 min | |||

| Chemical cleaning frequency | 30-180 day | |||

| Chemical cleaning duration | 90-480 min | |||

| Chemical cleaning chemicals | NaClO Or H2O2 (500ppm), NaOH(pH≤12), HCl(pH≥2) |

NaClO Or H2O2 (2000ppm), NaOH(pH≤10), HCl(pH≥2) |

NaClO Or H2O 2 (100ppm), NaOH(pH≤10), HCl(pH≥2) |

|

External pressure VS Internal pressure

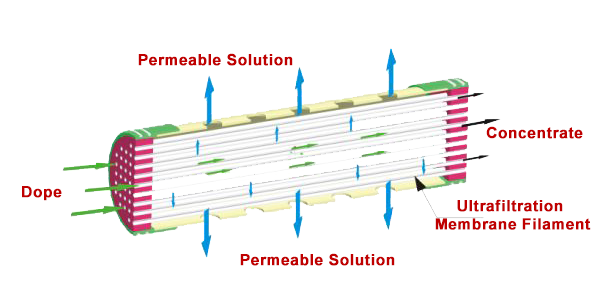

External pressure(outside-in)

he original liquid is driven by the pressure difference , penetrates radially from the outside to the inside, through the hollow fiber to become the osmotic fluid, and the trapped concentrated material is collected in the outside of the hollow

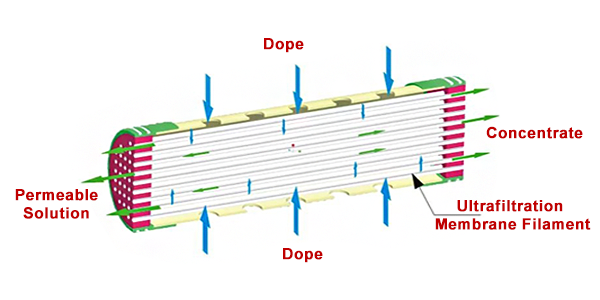

Internal pressure(in-outside)

The original solution into the hollow fiber membrane, driven by the pressure difference, radial from inside to outside through the hollow fiber into osmotic fluid, concentrated liquid is left in the hollow fiber, from the other end out.

Products

Workshop Production

Customization is accepted and alternatives to other brands of products can be provided.

Real Case