MBR Membrane

Wastewater Treatment System

Water Treatment System & Membrane Selection and Ordering Can Be Easy & Safe

Whether you are replacing an old project or designing a new project, we can provide it for you based on our rich experience. We have professional sales staff to connect with you to solve all your problems from purchasing to using the MBR membrane.

Membrane Bioreactor (MBR)

for Wastewater Treatment

We can provide flat membranes, hollow fiber membranes and sewage treatment components, including sewage treatment solution design and subsequent maintenance guidance

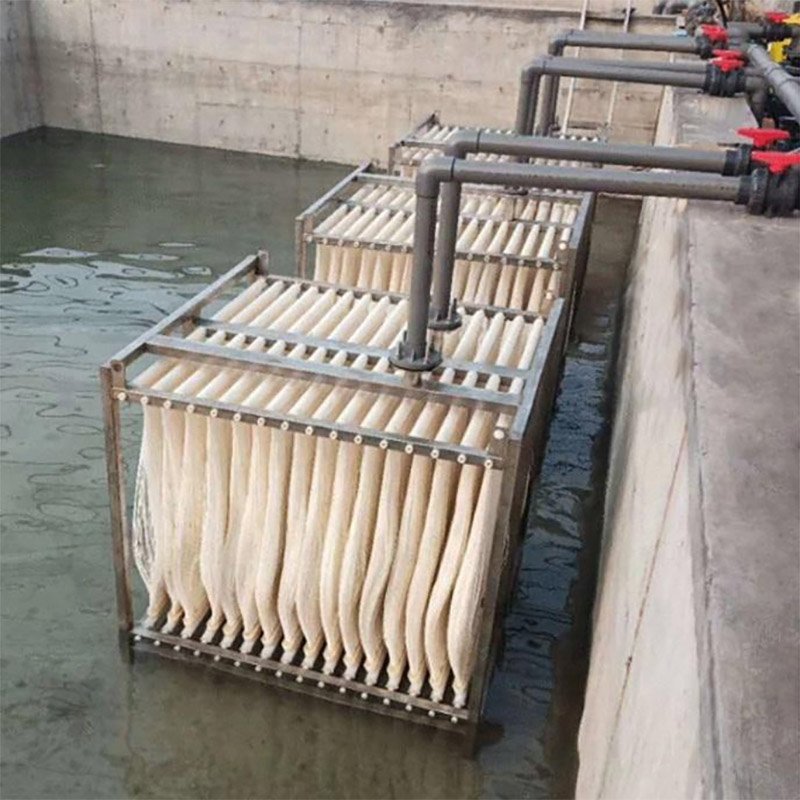

Flat Sheet MBR

Flat sheet (FS) membranes have planar configuration and are predominantly rectangular. They are designed to be immersed in the membrane tank, and scoured with air to maintain the flow of sludge through the membrane channels

Hollow Fiber MBR

PVDF hollow fiber MBR is made of modified PVDF material, with high flux, good chemical resistance and pollution resistance. The polyester interlayer support net greatly increases the mechanical strength of the membrane silk.

What is the difference

between hollow fiber and flat sheet MBR?

Hollow fibre configurations, comparing to the flat sheet, are designed for higher fluxes, operated at lower concentrations, cleaned more often and protected by stricter pre-treatment. Filterability of activated sludge from municipal MBRs is better than from industrial MBRs and does not depend on membrane configuration.

| Comparison | Flat Sheet MBR | Hollow Fiber MBR |

| Usage rate | Around 15% | Around 85% |

| Material | PVDF | PVDF |

| MBR membranes for filtering sewage treatment and reuse require materials with strong oxidation resistance, so PVDF's superior oxidation resistance than other materials (such as PE) determines that PVDF materials are the mainstream materials for MBR membranes. | ||

| Flux | 10L/m²/h ~ 40L/m²/h | 10L/m²/h ~ 40L/m²/h |

| Pre-processing requirements | No Special Requires | Requires removal of as much hair as possible into the water |

| Hollow fibers have the risk of being tangled by hair, so care must be taken when handling domestic wastewater, including hair or thread-like fibers | ||

| Packing density | Taking Toray TMR140-100s as an example, excluding the membrane separation volume, the area of 140m2 membrane needs to occupy 2.756 m3 | Take Dow FLEXELL as an example, calculate the membrane separation volume, 80m2 membrane surface Product needs to occupy 0.7056m3 |

| The filling density of hollow fiber MBR is more than twice that of flat MBR, saving land occupation and biochemical space | ||

| Pollution recovery Method | Air scrubbing, chemical cleaning | Backwash, air scrub, chemically enhanced backwash, chemical cleaning |

| Can not backwash is the biggest defect of flat membranes. Backwashing is the most ideal pollution recovery method for the membrane industry (including MBR, microfiltration, ultrafiltration). Failure to backwash to restore membrane pollution will shorten the chemical cleaning cycle of the membrane. The main reason for the roll-out ultrafiltration to completely withdraw from the ultrafiltration market is that it cannot be backwashed. | ||

| Operational risk | Diaphragm risk of breakage, such as "fat belly" phenomenon | Risk of fiber broken |

| The flat membrane is easy to rupture. When the machine is taken out during shutdown, the water inside the membrane bag will be collected by the gravity under the membrane bag and the membrane will be broken. The risk of hollow fibers is that if the strength of the membrane filament is insufficient, filament breakage may occur, but with the breakthrough of membrane-forming technology, especially the thermal membrane process (TIP process), the strength of membrane filaments has increased It is more than ten times, which basically eliminates the filament breakage phenomenon of the hollow fiber membrane during operation. | ||

| Self-healing | No self-healing function | Has self-healing function |

| After the flat membrane is damaged, the entire membrane must be replaced; if the hollow fiber is broken, the small flow path of the hollow fiber will be blocked by sludge, which can repair itself without replacing the membrane element. | ||

| Component structure | Large modular | Integrated configuration using single element |

| Overhaul and maintenance need to set up large lifting equipment, lift out the module | When maintenance and repair is required, a single person can remove it without tools. Easy maintenance | |

| Energy consumption | The air-water ratio is generally above 30: 1. Air-to-water ratio, air intake or water intake consumes energy, power equipment | Using pulse gas, the gas-water ratio is generally around 3: 1 ~ 5: 1 |

| Large gas consumption during operation | Low gas consumption during operation, low energy consumption | |

| Chemical Wash | Chemical immersion combined with manual scrubbing | Chemical immersion |

| Cleaning is complicated and requires a lot of labor | Simple cleaning, can be done automatically and can be operated by one person | |

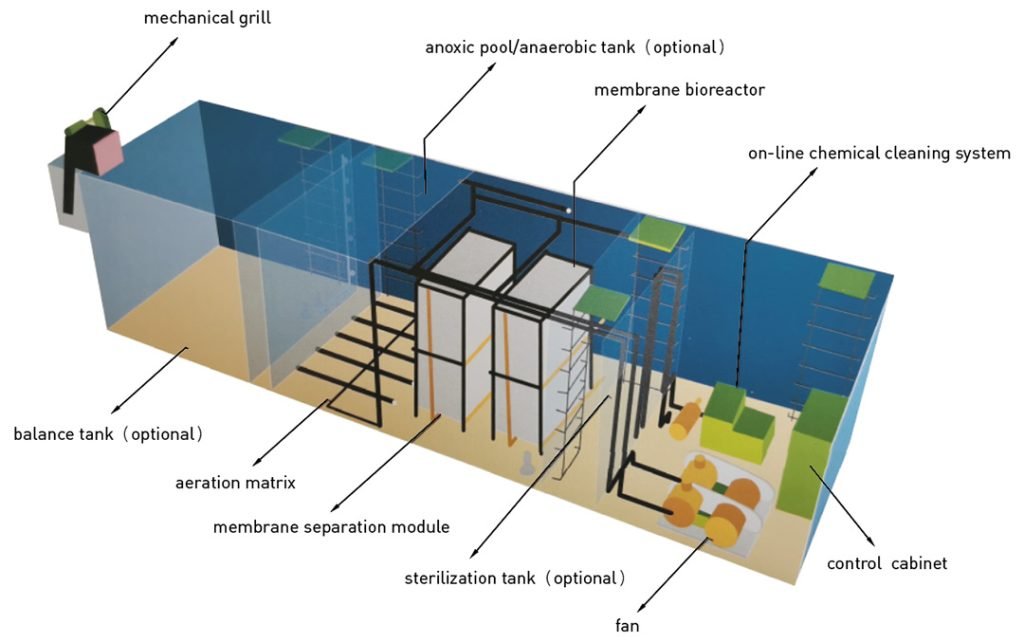

Membrane Bioreactors (MBRs) Advantages And Application

Membrane Bioreactors (MBRs) can be broadly defined as a system that combines wastewater biodegradation with membrane filtration. They have proven to be very effective in removing organic and inorganic pollutants as well as biological entities from wastewater.There are many types of MBR such as tubular, plate and hollow fiber. Among them, hollow fiber PVDF material has been proven to be the most reasonable in price and good in performance. The membranes used had pore sizes ranging from 0.01 to 0.4 µm.

Advantages of the MBR

- It include good control of biological activity or Automatical control whole STP System, less labor cost.

- High quality effluent free of bacteria and pathogens

- Smaller plant size (Lower space required because of higher MLSS short HRT-hydraulic retention time )

- Higher organic loading rates.

The Application of MBR

Current the MBR is widely apply to all types of wastewater, the applications include water recycling in buildings, wastewater treatment for small communities, industrial wastewater treatment, and landfill leachate treatment, and agricultural wastewater processing.

1 ). Applications in municipal wastewater treatment

MBR systems were initially used for municipal wastewater treatment, primarily in the area of water reuse and recycling. Compactness, production of reusable water, and trouble-free operation made the MBR an ideal process for recycling municipal wastewater in water and space limited environments.

2) Applications in industrial wastewater treatment

High organic loadings and very specific and difficult to treat compounds are two major characteristics of industrial waste streams that render alternative treatment techniques such as the MBR desirable. Since, traditionally wastewater with high COD content was treated under anaerobic conditions, initial attempts

of MBR applications for industrial wastewater were in the field of anaerobic treatment,Also effective removal of nitrates, herbicides,pesticides, and endocrine disrupting compounds may be achieved by MBRs.

3) Applications in fields of landfill leachate, sludge digestion, and human excrement

In addition to municipal and industrial wastewater treatment,MBRs have been utilized in a number of other areas. One such area is the treatment of landfill leachates. Landfill leachates usually contain high concentrations of organic and inorganic compounds. Conventionally, the treatment of leachates involves a physical, biological, or membrane filtration process (or a combination of them). MBR systems have been successfully utilized with an additional treatment step for inorganics and heavy metal removal, such as Nano Filtration and reverse osmosis (RO). Several industrial scale plants, combining a MBR, Nano filtration and a reverse osmosis system, are presently operated

MBR sewage treatment integrated equipment

Application Cases