Hollow Fiber MBR Membrane

CM MBR Membrane for Wastewater Treament

Our MBR membrane replacement, we have had many replacement cases

Water Treatment System & Membrane Selection and Ordering Can Be Easy & Safe

Whether you are replacing an old project or designing a new project, we can provide it for you based on our rich experience. We have professional sales staff to connect with you to solve all your problems from purchasing to using the mbr membrane.

Membrane Bioreactor Basic Operating Parameters

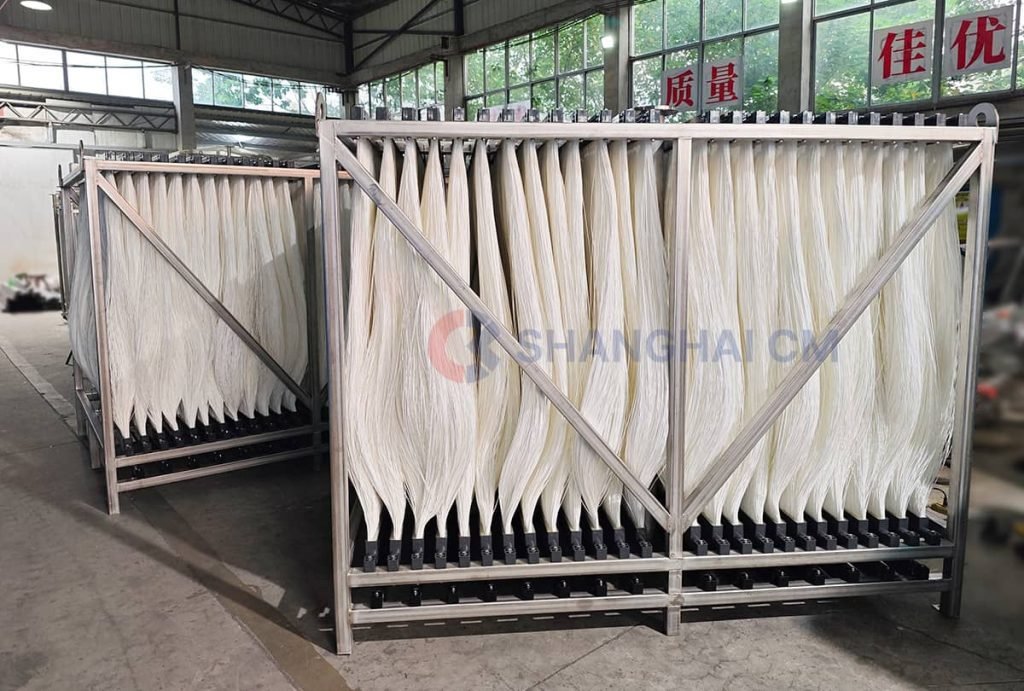

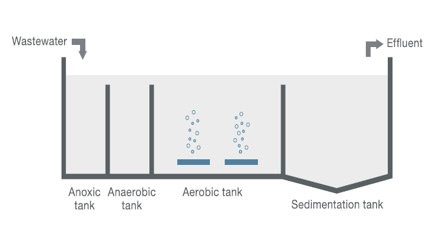

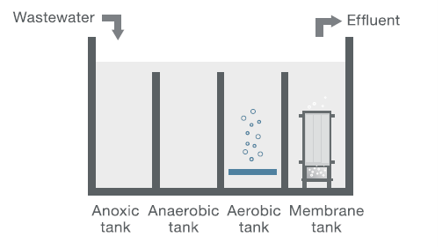

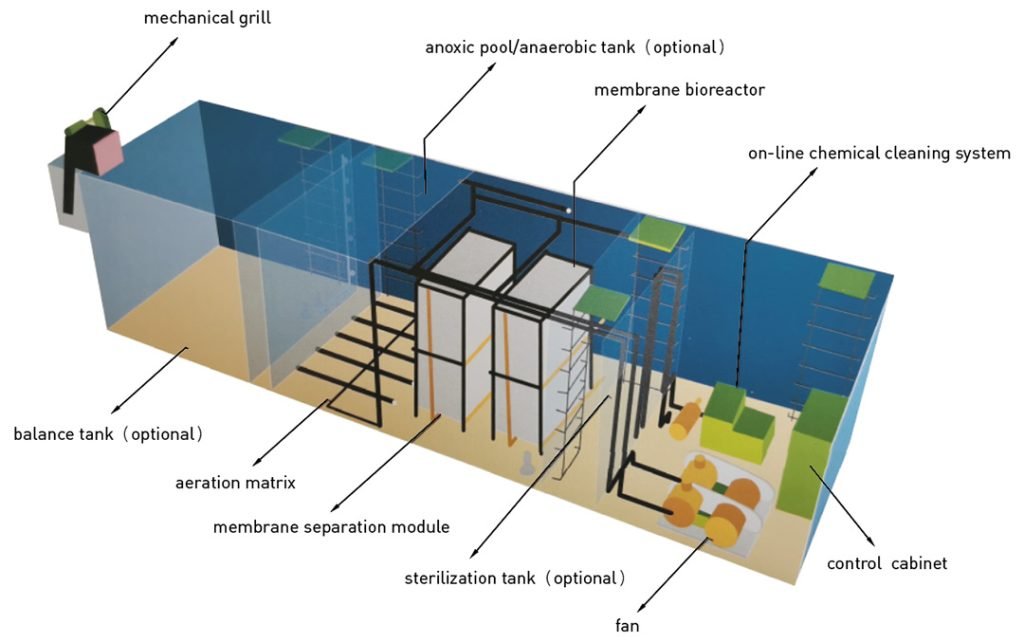

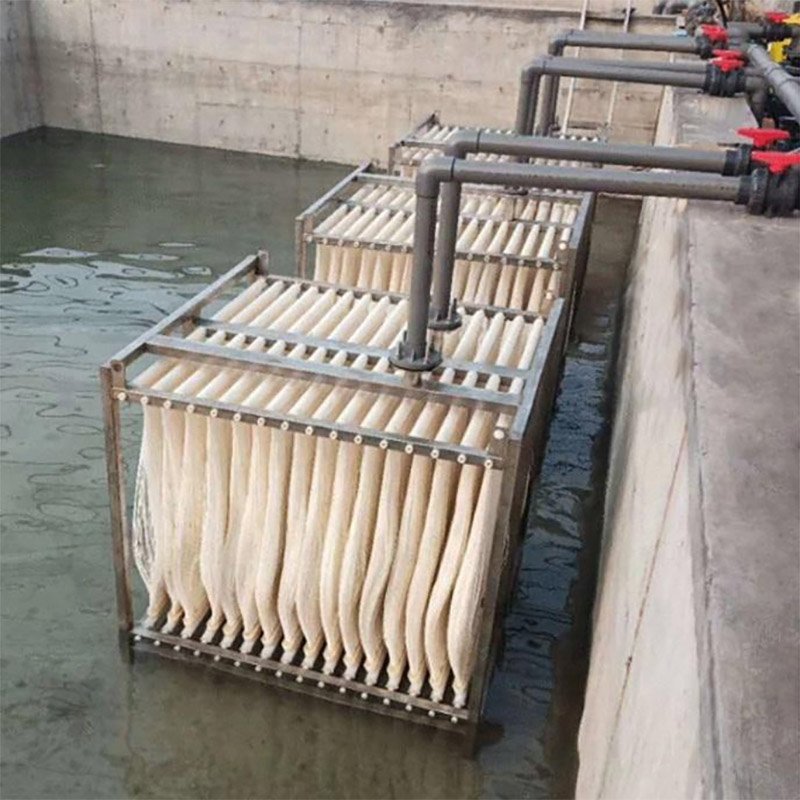

Membrane bioreactors were designed with the separation device located external to the reactor (side-stream MBR) and relied on high transmembrane pressure (TMP) to maintain filtration. The introduction of a submerged membrane bioreactor system, with the membrane directly immersed in the bioreactor, quickly led to it becoming the preferred configuration, especially for typical North American wastewater treatment.

The submerged membrane bioreactor relies on coarse bubble aeration to produce mixing and limit fouling. The energy demand of the submerged system is much less than that of the side-stream systems. Whereas, submerged systems operate at a lower flux, demanding more membrane area. In submerged configurations, aeration is considered as one of the major parameters in process performance, both hydraulic and biological. Aeration maintains solids in suspension, scours the membrane surface, and provides oxygen to the biomass, leading to better biodegradability and cell synthesis.

Membrane bioreactors (MBR) offer an efficient and advanced biological treatment process compared to the conventional approach with primary and secondary clarifiers. The submerged membrane modules concept provide a long term and strong alternative in terms of process simplicity, space savings, civil works minimization and better effluent quality.

Why Choose Shanghai CM

Our MBR membrane has been running stably in more than 100 projects. We have been producing MBR Membrane for more than 10 years and have accumulated a lot of project experience.

- Short production cycle

We can produce 3000 square meters of Hollow Fiber MBR Membrane every day

- Great support

The staff you come into contact with are experienced and have working language skills in English and Russian

- Support customization

The number of membrane racks and the amount of membrane used can be specially designed according to your needs

- Construction Guidance

For new construction projects, we have experienced engineers who can guide the construction

First Generation

MBR Membrane

(Not have support frame)

Second Generation

MBR Membrane

(Have support frame)

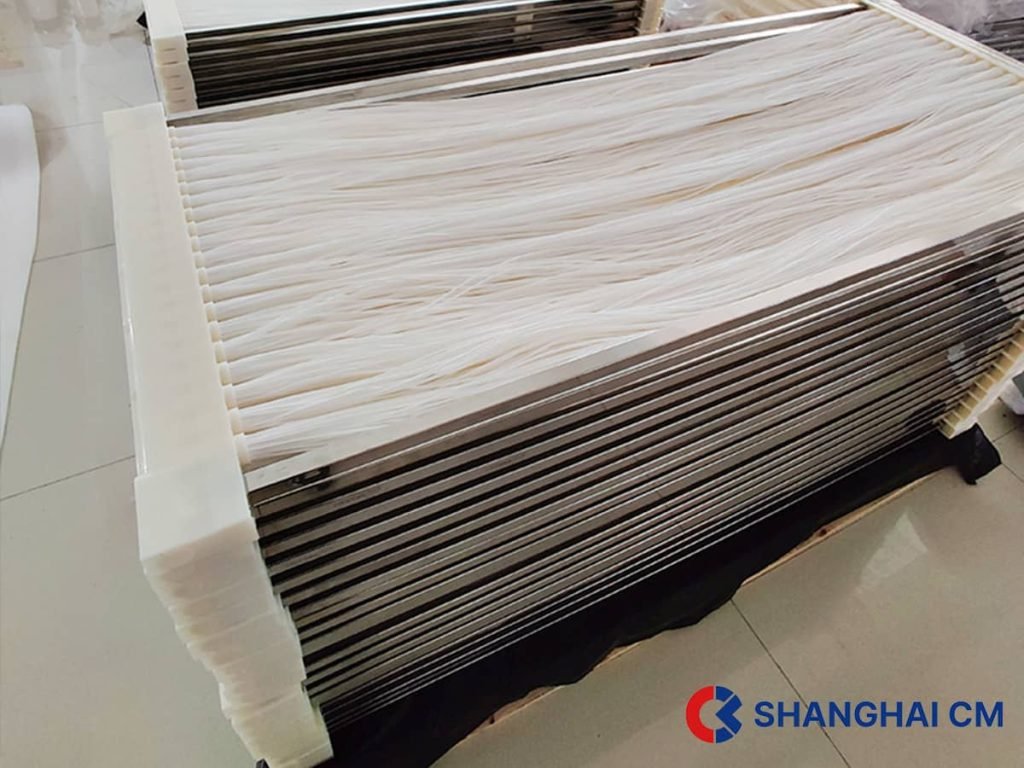

CM MBR Characteristic

The CM MBR module is an assembly system consisting of several components containing hollow fiber membrane modules.We can customize modules with the most suitable MBR components according to the capacity of different projects.

- Hydrophilic modified PVDF material

- Reinforced hollow fiber membrane

- Save 50-75% floor space

- Long membrane life

- Continuous and stable effluent quality

- Low pressure operation reduces system energy consumption

Shanghai CM's Services Always Go Extra Mile

No more wasting time on MBR membrane suppliers with poor quality. Shanghai CM's goal is to make you feel at ease. We are familiar with all project processes, from membrane pool design, membrane module size design to membrane module production, transportation and installation. We can provide full service and we have many successful cases for your reference.

OEM & ODM Available

If you have your own brand, we can print your logo on the MBR membrane

Customized design

Please tell us the amount of water processed by the project every day, and we can calculate the number of membrane modules required for you. Whether it is a replacement for an old project or a new project

Start With Low MOQ

No matter the size of your project, or if you need samples for testing, we support a minimum order of 1 module.

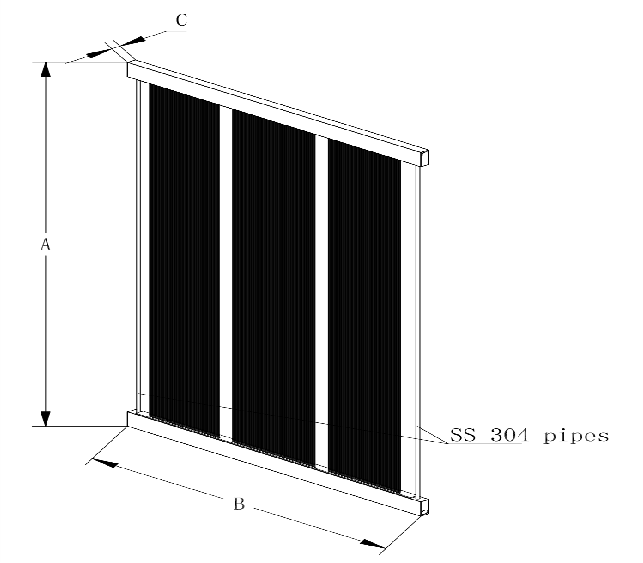

MBR Membrang Size Chart

Microfiltration MBR Membrane-0.2um

| Model No. | Membrane Surface Area(m2) | Fiber Material | Fiber Pore Size(um) | Dimentions(mm) | ||

| Height | Length | Width | ||||

| A | B | C | ||||

| CM-057 | 5.7 | Reinforced Polyvinylidene Fluoride (RPVDF) |

0.2um | 1,125 | 480 | 25 |

| CM-071 | 7.1 | 1,125 | 680 | 30 | ||

| CM-097 | 9.7 | 1,300 | 680 | 30 | ||

| CM-113 | 11.3 | 1,500 | 680 | 30 | ||

| CM-193 | 19.3 | 1,300 | 1,250 | 30 | ||

| CM-227 | 22.7 | 1,500 | 1,250 | 30 | ||

| CM-313 | 31.3 | 2,000 | 1,250 | 30 | ||

Ultrafiltration MBR Membrane-0.03um

| Model No. | Membrane Surface Area(m2) | Fiber Material | Fiber Pore Size(um) | Dimentions(mm) | ||

| Height | Length | Width | ||||

| A | B | C | ||||

| CM-060 | 6 | Reinforced Polyvinylidene Fluoride (RPVDF) |

0.03um | 1,125 | 480 | 25 |

| CM-088 | 8.8 | 1,125 | 680 | 30 | ||

| CM-120 | 12 | 1,300 | 680 | 30 | ||

| CM-140 | 14 | 1,500 | 680 | 30 | ||

| CM-238 | 23.8 | 1,300 | 1,250 | 30 | ||

| CM-282 | 28.2 | 1,500 | 1,250 | 30 | ||

| CM-388 | 38.8 | 2,000 | 1,250 | 30 | ||

MBR Sewage Treatment Integrated Equipment

100T/D MBR Sewage Treatment Integrated Equipment

MBR Sewage Treatment Integrated Equipment

100T/D MBR Sewage Treatment Integrated Equipment

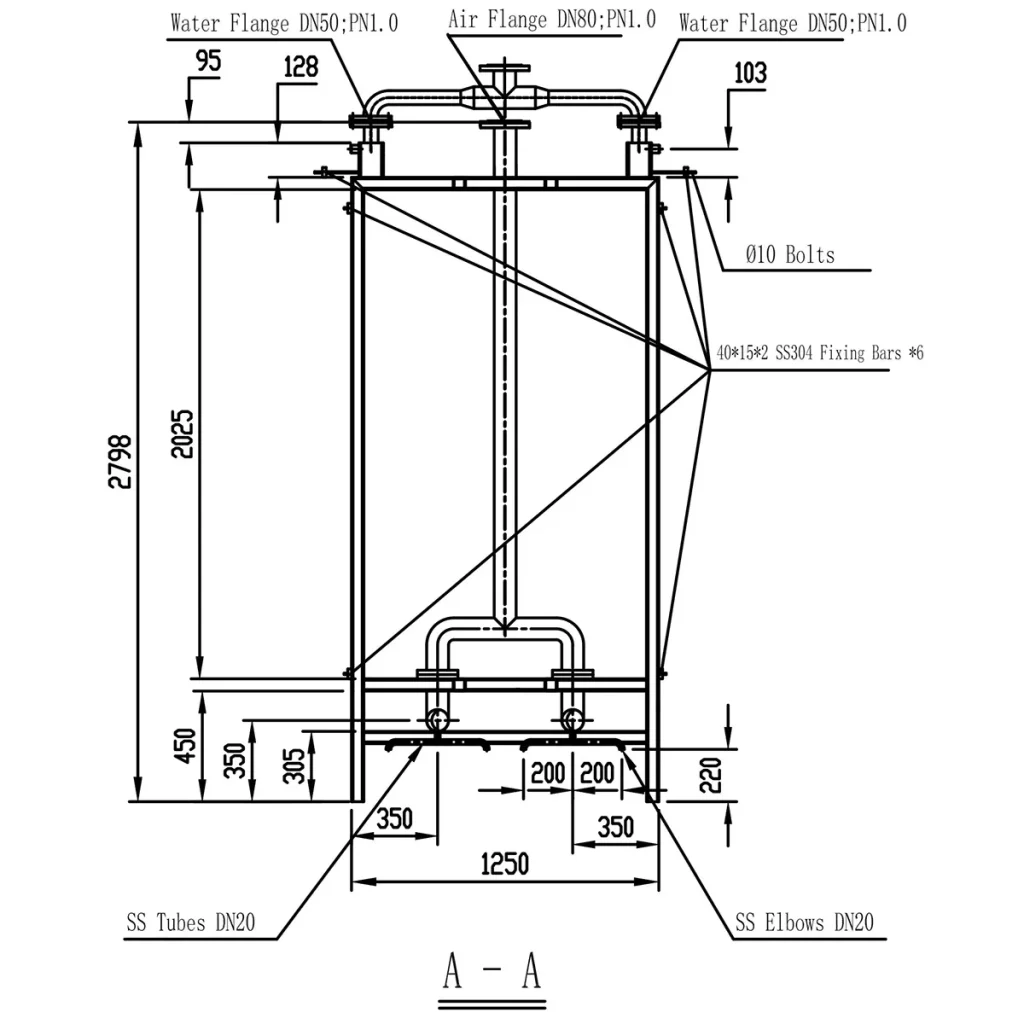

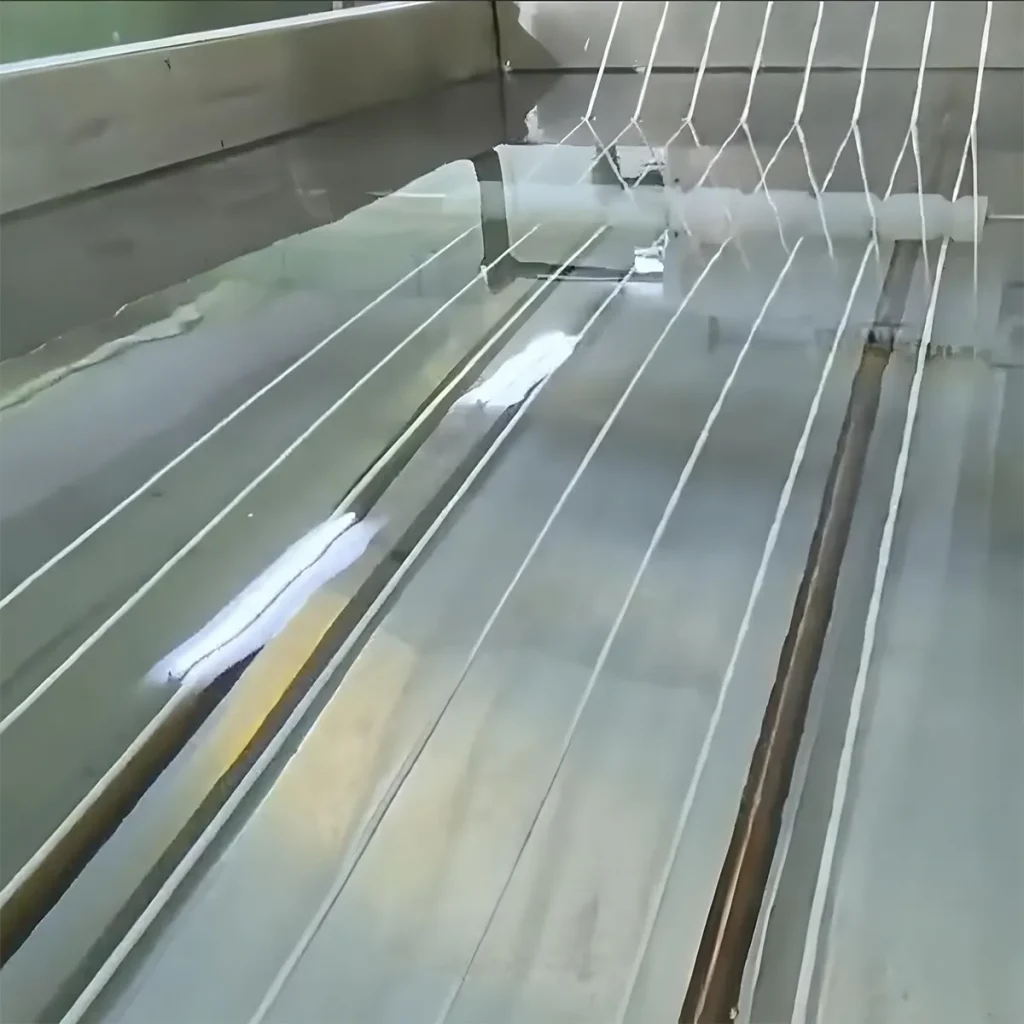

MBR Membrane Production Process

We have 3 production lines, each of which can produce 3,000 square meters of membrane modules per day, and the 3 production lines can simultaneously batch produce membrane modules of different specifications to achieve rapid delivery capabilities.

PVDF Raw Materials

The PVDF raw material has been repeatedly tested and has excellent hydrophilicity.

Using Advanced NIPS Technology

Ensure uniform film texture, stable performance and high tensile strength

Hollow fiber drying

The drying process helps to stabilize the membrane pore structure, making the membrane's filtration performance more precise, making the material's internal structure more stable, and enhancing its mechanical strength.

Batch Glue Filling

In a constant temperature and humidity environment, batch filling helps to ensure stable and consistent product quality

Production Completed

The MBR membrane modules that have been produced are protected with transparent films and are waiting to be packed.

MBR Membrane

Production Process

We have 3 production lines, each of which can produce 3,000 square meters of membrane modules per day, and the 3 production lines can simultaneously batch produce membrane modules of different specifications to achieve rapid delivery capabilities.

PVDF Raw Materials

The PVDF raw material has been repeatedly tested and has excellent hydrophilicity.

Using Advanced NIPS Technology

Ensure uniform film texture, stable performance and high tensile strength

Hollow fiber drying

The drying process helps to stabilize the membrane pore structure, making the membrane's filtration performance more precise, making the material's internal structure more stable, and enhancing its mechanical strength.

Batch Glue Filling

In a constant temperature and humidity environment, batch filling helps to ensure stable and consistent product quality

Production Completed

The MBR membrane modules that have been produced are protected with transparent films and are waiting to be packed.

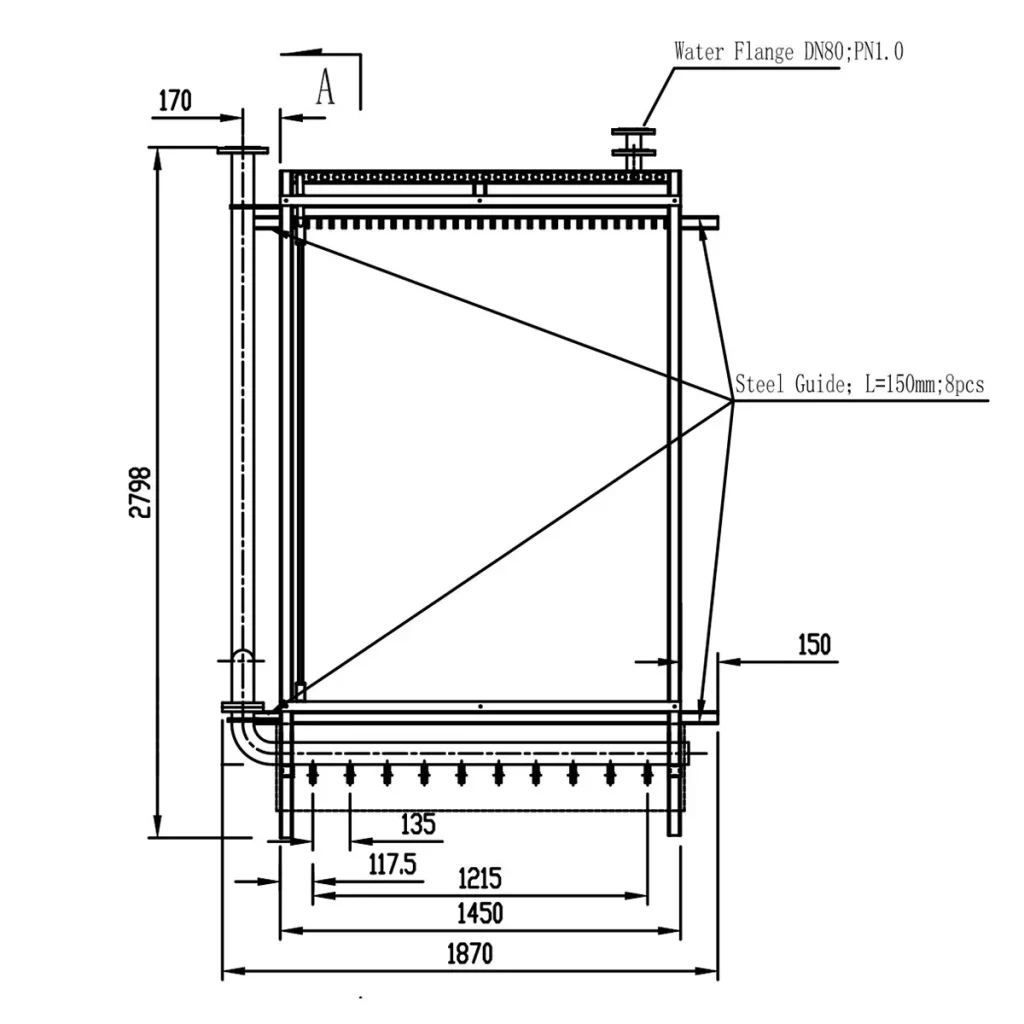

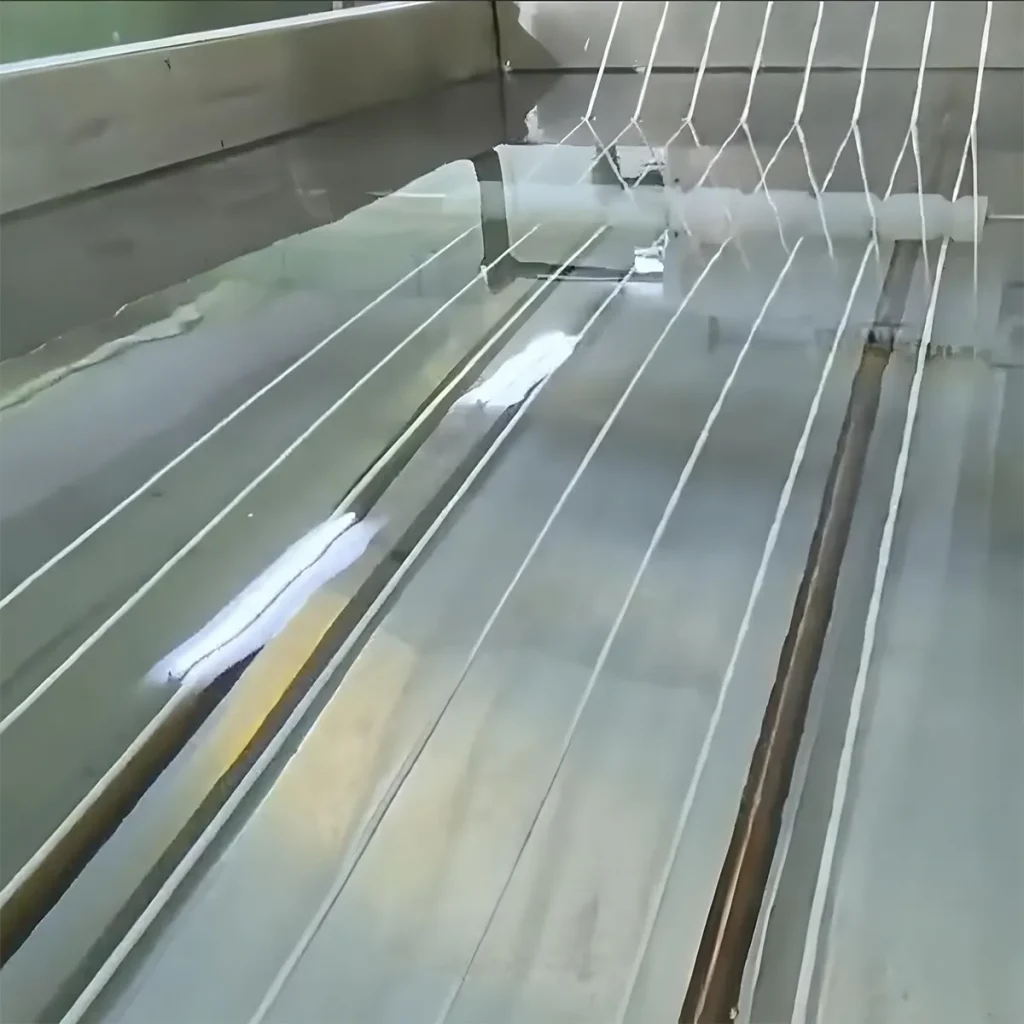

MBR Membrane Module Frame

- Highest solids tolerance of any hollow-fiber membrane

- Works through virtually any raw water quality change or upset

- Outside-in flow path provides a more robust system

- Fully automated for simplified design and operation

- Outstanding technology for virtually all wastewater treatment applications – from greenfield plants to retrofits to water reclamation projects

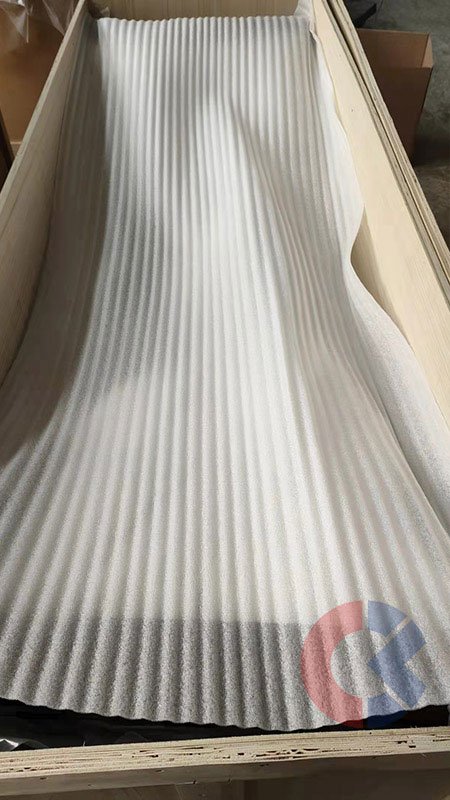

Package & Shipping

- Each piece membrane is protected by foam

- Both ends are fixed to reduce collisions during transportation

- Sturdy wooden box protects every piece membrane

- Each box has a quality inspection certificate

Our Happy Clients From 30+ Countries

I have been working with CM for 3 years and I am glad that I chose them from the beginning. Their product quality is very high and my customers have never complained about their products. Shanghai CM, as a professional manufacturer, has always provided us with professional technical support. At the same time, they also responded to all our technical issues in a timely manner, ensuring that my customers can get the equipment running smoothly.

Abdulla Bal

From Kazakhstan

We met at the Shanghai Water Treatment Exhibition. My colleagues and I visited their factory in person and were impressed by their advanced equipment. As a replacement project, the 500D membrane module provided by Shanghai Chenmo ran perfectly in the original system, which was great.

Giovamny Bernard

From ominican

During the entire purchase process, CM made me feel very safe. Their sales staff were very professional. Thank you for providing me with a design plan, which enabled our sewage treatment plant project to be implemented quickly. Now the entire sewage treatment plant project is running stably, and everything looks very good.

Dmitry Mileshkin

From Russia

Application Cases

More to read

chris Li

Hi, I'm Chris Li. I'm the father of a 6-year-old boy, and I've also worked in the water treatment industry for 16 years. I would like to share some of my understanding of this industry with you, and I hope it can be helpful.