CM Ultrafiltration Membrane UF 219 PES

Product Information

Membrane Polymer: PES

Nominal Membrane Area: 55 ㎡

Nominal pore size: 0.02 μm

Fiber Dimensions: ID 0.8 mm

Typical Filtrate Flux Range: 60-120 L/㎡/h

Operating Mode: Inside to Outside Filtration

Product Overview

PES (Polyether sulfone) ultrafiltration membranes are highly regarded in the water treatment industry for their exceptional performance. The key advantages of PES membranes include high chemical stability, which allows them to withstand various acids, bases, and organic solvents, making them suitable for diverse water treatment applications. They also exhibit excellent mechanical strength, ensuring structural stability under prolonged operation. PES membranes provide superior permeability and selectivity, effectively removing suspended particles, bacteria, and large molecular organic compounds while maintaining high water flux to enhance filtration efficiency. Additionally, PES membranes have strong thermal resistance, remaining stable at high temperatures and making them ideal for processes requiring high-temperature sterilization. Furthermore, their good biocompatibility and low protein adsorption characteristics make them widely used in pharmaceuticals and the food industry, ensuring the purity and safety of products. These combined properties make PES ultrafiltration membranes widely applicable in municipal water treatment, industrial wastewater treatment, food and beverage processing, and biopharmaceutical sectors.

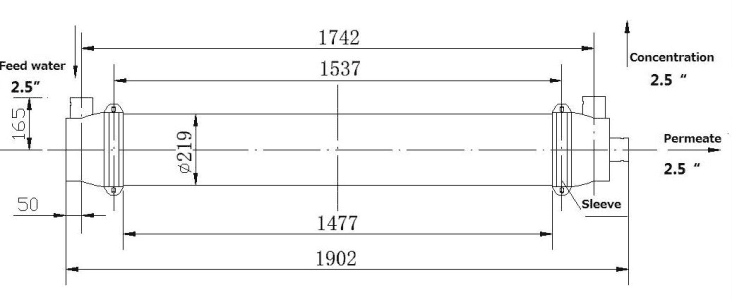

Product Dimensions

Product Parameters

| Type Configuration:Capillary Ultra filtration Module | |

| Membrane Polymer | PES |

| Nominal Membrane Area | 55 ㎡ |

| Nominal pore size | 0.02 μm |

| Fiber Dimensions | ID 0.8 mm |

| Application Date(for General use) | |

| Typical Filtrate Flux Range | 60-120 L/㎡/h |

| Maximum Applied Feed Pressure | 0.5 Mpa |

| Maximum Tran membrane Pressure | 0.3 Mpa |

| Maximum Backwash Pressure | 0.3 Mpa |

| Operating Temperature Range | 5-40 ℃ |

| pH Operating Range | 2-12 (During Chemical Washing 1-13) |

| Operating Module | Inside to Outside Filtration |

Real Pictures

Download

FAQ

How long do ultrafiltration membranes last ?

The lifespan of ultrafiltration membranes varies depending on factors such as water quality, system design, and maintenance practices. On average, UF membranes can last between 3 to 7 years. Regular monitoring and maintenance can help extend their service life.

What are the benefits of using ultrafiltration membranes ?

- High removal efficiency of pathogens and suspended solids

- Consistent water quality

- Compact system design

- Low chemical usage compared to conventional methods

- Easy integration with other water treatment processes

What are the main applications of ultrafiltration membranes ?

- Drinking water treatment

- Wastewater treatment

- Industrial process water

- Food and beverage processing

- Pharmaceutical manufacturing

- Desalination pretreatment

Could you provide a detailed quotation and an estimated delivery time ?

We will provide a detailed quotation based on your specific needs. Generally, our delivery time is 2-4 weeks after contract signing. We can also adjust the delivery schedule based on your project urgency.

What are your after-sales service and warranty policies ?

We provide a 12-month warranty period. We are responsible for any quality issues of the product during the warranty period. After the warranty period, we can still provide technical services to ensure that the system can run stably.

Do your products comply with international certification standards ?

Our membrane bioreactors have obtained ISO 9001 quality management system certification and CE certification, complying with international safety and quality standards. We regularly conduct quality inspections and tests to ensure continuous compliance with these standards.

Do you offer installation and maintenance services ?

We can provide detailed technical guidance and send technical engineers to the site to guide installation and commissioning when necessary.

Exthbition

Shanghai CM's 2023 global exhibition live events

Manila, Philippines

Mar 22-24, 2023

Jakarta, Indonesia

Aug 31-Sep 1, 2023

Moscow, Russia

Sep 12-14, 2023

Dubai, United Arab Emirates

Nov 15-17, 2023

More to read

chris Li

Hi, I'm Chris Li. I'm the father of a 6-year-old boy, and I've also worked in the water treatment industry for 16 years. I would like to share some of my understanding of this industry with you, and I hope it can be helpful.