Water Treatment Systems

If you are looking for a professional ro systems and part manufacturer in China, then Shanghai CM can be your first choice. CM has been an expert ro systems and part supplier in China since 2009. We can provide you turn key water treatment solutions.

Call Us

+86 18221094035

chris@shchenmo.com

Address

No. 1188 Jiangyue Road, Minhang District, Shanghai

Shanghai CM Brings for You

Diverse Water Treatment Equipments

Simple Style RO System

Capacity ranging from 250 to 500+ L/H, suitable for Household Restaurants and Construction Sites

Commercial RO System

Capacity ranging from 500 to 5,000+ L/H, suitable for coffee shops, restaurants, hotels, guesthouses, and resorts

Industrial RO System

Capacity ranging from 5,000+ L/H, suitable for Water bottling plants, beverage production plants and factories

Need help choosing the right water treatment system for your business?

Reverse Osmosis Water Filter with High-Quality

Our RO systems boast remarkable flexibility and feature a built-in UV sterilizer, guaranteeing pure and pollution-free water. With a 99.9% contaminant removal rate, CM's reverse osmosis technology delivers unparalleled water purification.

Health & Wellness Benefits

Experience the benefits of remineralization for alkaline water, promoting health and wellness through advanced water treatment technology.

Directly access pristine mineral water through a dedicated tap in real-time, revolutionizing your hydration experience. Complementing our residential solutions, we offer high-capacity commercial water softeners, catering to diverse needs and delivering premium-quality softened water.

Elevate Your Water Quality with CM's Innovative Solutions

Where simplicity meets sophistication - Experience the future of water purification technology today.

What is the RO System?

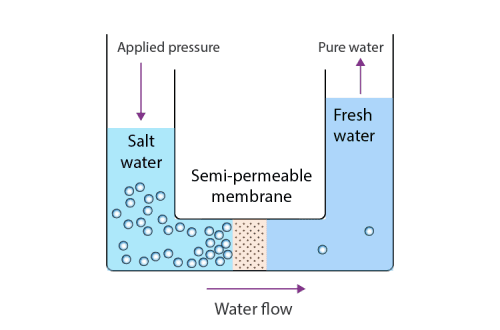

The RO system employs a semi-permeable membrane to eliminate impurities, contaminants, and particles from water. It operates by applying pressure to the water, forcing it through the membrane and leaving behind substances that could compromise the water's integrity.

How Reverse Osmosis Works

Reverse Osmosis works by using a high-pressure pump to increase the pressure on the salt side of the RO and force the water across the semipermeable RO membrane, leaving almost all (around 95 to 99%) dissolved salts in the reject stream behind.

Pretreatment Components

Essential pretreatment stages ensure optimal RO membrane performance and longevity by removing various contaminants before water reaches the membrane.

Activated Carbon

Filled with activated carbon granules, it utilizes adsorption to eliminate residual chlorine, organic matter, odors, and some colloids. This prevents oxidative damage to RO membranes caused by residual chlorine while improving water taste.

Quartz Sand

Composed of multiple layers of quartz sand with varying particle sizes, it physically intercepts and removes suspended solids, sediment, and other large particles from raw water, reducing turbidity and alleviating the burden on subsequent filtration stages.

Softening Resin

Loaded with sodium ion exchange resin, it removes calcium and magnesium ions through ion exchange, reducing water hardness. This prevents scaling on the RO membrane surface, thereby extending membrane lifespan.

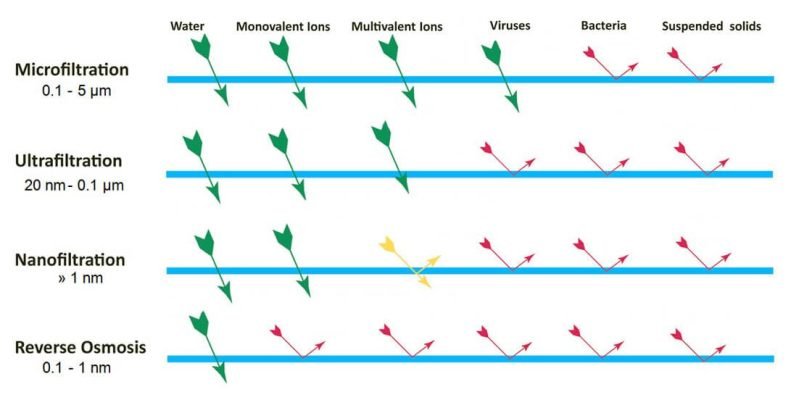

Cartridge Filter

Equipped with a 5μm precision filter cartridge, it serves as the final barrier in pretreatment, intercepting any remaining fine particles to ensure water entering the RO membrane meets quality standards.

Ready to Learn More About RO Systems?

Discover how our advanced RO technology can provide you with the purest water solution.

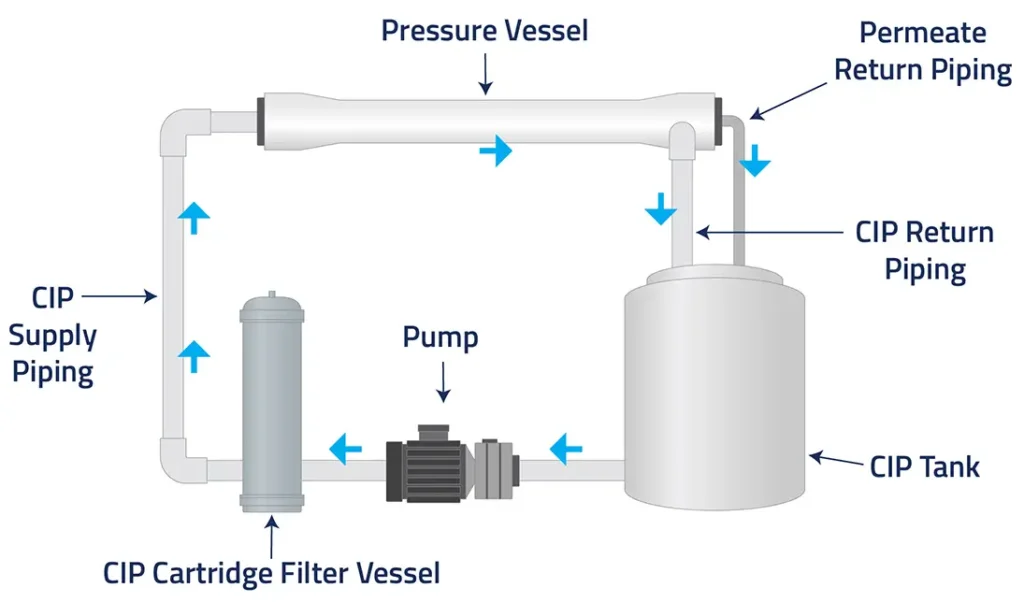

CIP Process for RO System

The main reason for chemical cleaning (chemical cleaning or CIP, i.e., in-place cleaning) of reverse osmosis membrane systems is to restore the performance of the membrane, prolong the service life of the membrane, and ensure the efficient and stable operation of the system. Conventional physical cleaning (e.g., low-pressure washing, air scrubbing) can only remove loose contaminants from the membrane surface, while chemical cleaning can more thoroughly remove stubborn contaminants (e.g., scaling, biofilm, etc.) through the dissolution, dispersion, oxidation or sterilization of chemical reagents.

Membrane Performance Restoration

Chemical cleaning effectively restores membrane permeability and selectivity by removing accumulated contaminants that physical cleaning cannot eliminate.

Extended Membrane Life

Regular CIP procedures significantly extend membrane service life by preventing irreversible fouling and maintaining optimal operating conditions.

System Efficiency

Thorough chemical cleaning ensures stable system operation by removing scaling, biofilm, and other stubborn contaminants through specialized chemical processes.