Food and beverage plants face brutal wastewater challenges. High organic loads, fats, oils, and strict discharge limits create expensive treatment headaches that conventional systems cannot solve.

MBR technology consistently delivers 95-99% BOD removal for food processing wastewater while enabling water reuse and meeting the strictest discharge standards. These five case studies show actual results from dairy, brewery, meat processing, snack food, and juice production facilities.

I have worked with food processors for over 15 years, and their wastewater problems keep getting worse. Stricter regulations, higher disposal costs, and water scarcity force them to find better solutions than conventional treatment.

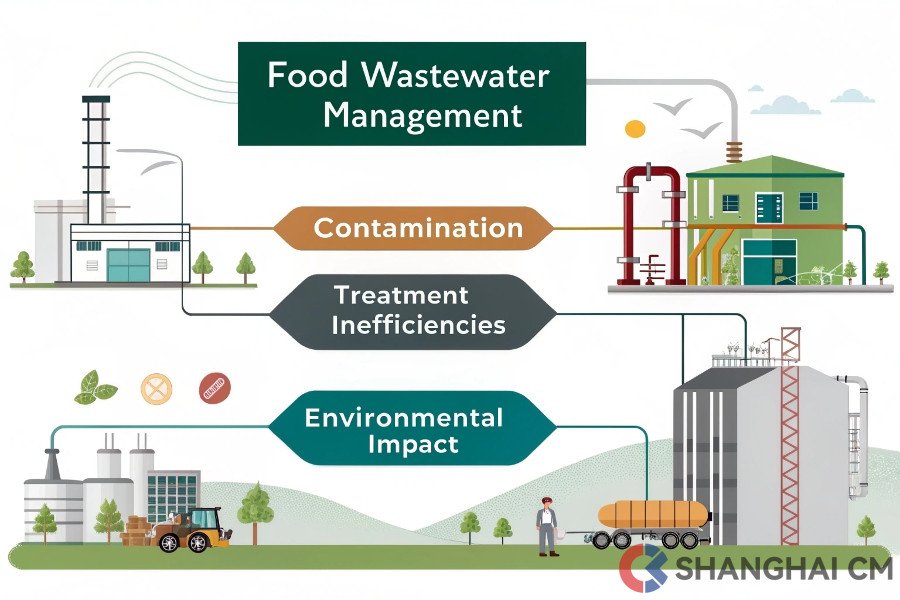

Why Food Processing Wastewater Destroys Conventional Systems?

Food and beverage wastewater creates perfect storms for treatment plants. The combination of extreme loads and variable flows overwhelms standard biological systems.

Food processing creates wastewater with BOD levels 10-100 times stronger than municipal sewage, plus fats, oils, proteins, and cleaning chemicals that disrupt biological treatment. Peak loads during production shifts can exceed design capacity by 300-500%.

The Numbers Tell the Story

Municipal wastewater typically contains 200-300 mg/L BOD. Food processing wastewater ranges from 2,000-30,000 mg/L BOD depending on the product. Dairy plants produce 4,000-8,000 mg/L BOD, while meat processors can exceed 15,000 mg/L during peak production.

Conventional activated sludge systems fail at these concentrations. The biological process becomes unstable, clarifiers overflow, and effluent quality swings wildly. I have seen plants pay millions in penalties because conventional treatment could not handle their loads consistently.

Shock Loading Kills Performance

Food plants operate in batches with extreme flow variations. A brewery might discharge 80% of daily wastewater in just 6-8 hours. This hydraulic shock combined with organic loading spikes overwhelms conventional systems designed for steady municipal flows.

Case Study 1: Midwest Dairy Processing Plant - From Violations to Water Reuse Champion

The Problem: A 500,000 gallon per day dairy plant faced chronic permit violations and $50,000 monthly penalties. Their conventional system could not handle milk protein loads and cleaning chemical shocks from CIP operations.

The plant processed 2 million pounds of milk daily, creating wastewater with 6,000-12,000 mg/L BOD and 800-1,200 mg/L TSS. Peak discharge occurred during 4-hour CIP cycles that sent caustic and acid cleaning solutions to the treatment plant.

Their existing activated sludge system produced effluent averaging 180 mg/L BOD and 95 mg/L TSS. State regulators required 30 mg/L BOD and 30 mg/L TSS, making violations inevitable.

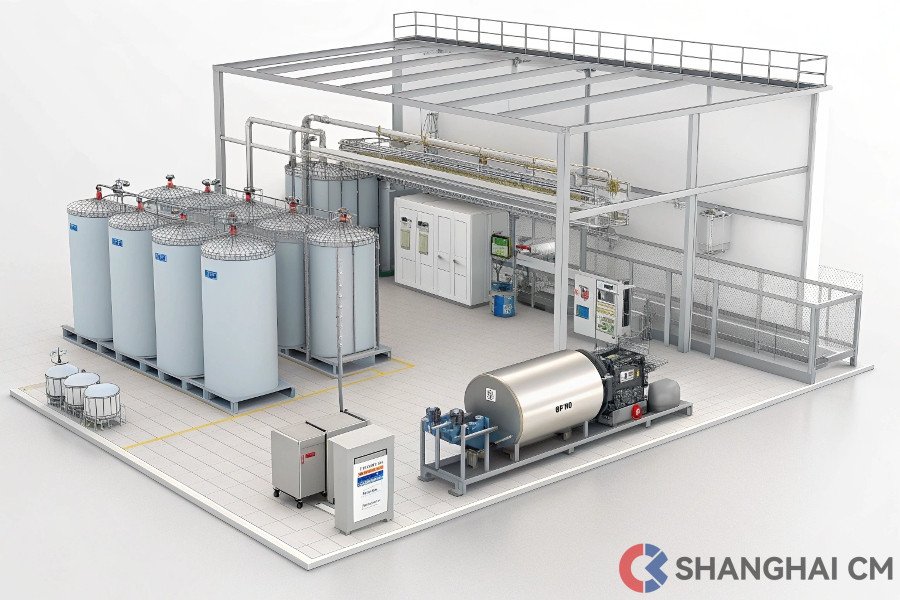

The MBR Solution: We installed a 0.5 MGD MBR system with pre-treatment for FOG removal and pH adjustment. The system included equalization tanks to buffer shock loads and specialized membrane modules designed for high organic applications.

The design incorporated automated cleaning cycles, redundant blowers, and remote monitoring. We sized the biological system for peak organic loads rather than average flows to handle CIP shocks.

The Measurable Results: The MBR system achieved remarkable performance improvements that transformed the plant's operations and compliance status.

- BOD removal: 99.2% (effluent averaging 8 mg/L vs permit limit of 30 mg/L)

- TSS removal: 99.8% (effluent averaging 2 mg/L vs permit limit of 30 mg/L)

- Eliminated all permit violations within 90 days of startup

- Generated $180,000 annual savings from avoided penalties

- Enabled CIP water reuse worth $85,000 yearly in reduced municipal water costs

- Reduced sludge disposal costs by 65% due to lower sludge production

The plant now reuses 40% of treated effluent for non-contact applications including vehicle washing, equipment cooling, and landscaping irrigation.

Case Study 2: Craft Brewery Chain - Meeting Strict Limits While Scaling Production

The Problem: A rapidly growing craft brewery faced tightening municipal discharge limits just as they planned to triple production capacity. Their existing dissolved air flotation system could not meet new 50 mg/L BOD limits.

The brewery produced 15,000 barrels annually with plans to reach 45,000 barrels within three years. Wastewater contained 3,000-8,000 mg/L BOD from yeast, grain solids, and cleaning operations. Production occurred in 8-12 hour batches creating extreme load variations.

Municipal pretreatment limits dropped from 300 mg/L to 50 mg/L BOD, with surcharge fees of $8 per pound for exceedances. At full production, surcharges would exceed $200,000 annually.

The MBR Solution: We designed a modular MBR system sized for ultimate capacity but built in phases to match production growth. The system included automated screening, equalization tanks, and anaerobic pretreatment to reduce organic loads.

The biological system used extended aeration to handle alcohol and yeast loads. Membrane selection focused on fouling resistance with automated cleaning cycles every 30 minutes during peak loads.

The Measurable Results: The phased MBR installation delivered consistent performance through rapid production increases and seasonal variations.

- BOD removal: 98.8% (effluent averaging 35 mg/L from 5,000 mg/L influent)

- Consistently met 50 mg/L discharge limits through tripled production

- Eliminated $180,000 in projected municipal surcharges

- Reduced water consumption 25% through process water reuse

- Handled seasonal production spikes without performance degradation

- Achieved 99.5% system uptime over 18 months of operation

The brewery now uses treated effluent for equipment cooling and cleaning, saving $45,000 annually in municipal water costs.

Case Study 3: Regional Meat Processing Facility - Nitrogen Removal in Minimal Space

The Problem: A 200,000 square foot meat processing plant needed advanced nutrient removal to meet new watershed protection standards but had no land available for conventional treatment expansion.

The facility processed 1,200 head of cattle weekly, generating wastewater with 12,000-18,000 mg/L BOD, 2,500 mg/L TSS, and 450 mg/L total nitrogen. New regulations required total nitrogen below 10 mg/L to protect downstream water quality.

Their existing treatment system occupied the entire available space and could not accommodate nutrient removal retrofits. Conventional BNR systems would require 300% more tank volume.

The MBR Solution: We installed a compact MBR system with integrated biological nutrient removal in the existing treatment building footprint. The design included anoxic and aerobic zones for nitrogen removal plus chemical phosphorus removal.

Advanced process control optimized nitrogen removal while minimizing energy consumption. The membrane barrier allowed higher mixed liquor concentrations, reducing required tank volumes by 60% compared to conventional BNR.

The Measurable Results: The space-constrained MBR retrofit achieved advanced nutrient removal while improving overall treatment performance.

- Total nitrogen removal: 97% (effluent averaging 8 mg/L from 450 mg/L)

- BOD removal: 99.1% (effluent averaging 12 mg/L from 15,000 mg/L)

- TSS removal: 99.9% (effluent averaging 1 mg/L from 2,500 mg/L)

- Fit advanced treatment in 40% of conventional BNR footprint

- Achieved compliance 45 days ahead of regulatory deadline

- Avoided $2.3 million in off-site treatment construction costs

Case Study 4: Snack Food Manufacturer - Handling Seasonal Production Surges

The Problem: A potato chip manufacturer faced massive seasonal load variations when processing 40% of annual volume during peak harvest season. Their conventional system failed during surge periods.

Base production generated 50,000 GPD with 2,000 mg/L BOD. Peak season increased flows to 180,000 GPD with BOD spiking to 8,000 mg/L from potato starch and frying oil carryover. The existing lagoon system took months to recover from harvest season shocks.

The MBR Solution: We designed an MBR system sized for peak loads with variable operation capabilities. The system included oil separation, starch recovery, and flexible biological loading to handle feast-or-famine feeding patterns.

The Measurable Results: The MBR system maintained consistent performance through extreme seasonal variations.

- Handled 260% flow increase without performance degradation

- BOD removal: 98.5% during peak season (effluent 45 mg/L from 8,000 mg/L)

- Recovered potato starch worth $35,000 annually as byproduct revenue

- Enabled year-round discharge vs seasonal storage requirements

- Reduced treatment footprint 55% compared to upgraded lagoon system

Case Study 5: Juice Processing Plant - Zero Liquid Discharge Achievement

The Problem: A citrus juice processor in water-scarce California needed zero liquid discharge to secure production permits while handling high-sugar wastewater that fouled conventional membranes.

The plant processed 500 tons of citrus daily, creating 120,000 GPD wastewater with 15,000 mg/L BOD from fruit sugars and pulp. Water costs reached $8 per 1,000 gallons with discharge prohibited due to drought restrictions.

The MBR Solution: We implemented a two-stage MBR system with reverse osmosis for zero liquid discharge[^1]. The first MBR stage removed organics while the second polished water for RO feed quality.

The Measurable Results: The integrated MBR-RO system[^2] achieved true zero liquid discharge[^1] while maximizing water recovery.

- Water recovery: 92% for process reuse and irrigation

- BOD removal: 99.4% enabling reliable RO operation

- Eliminated 40 million gallons annual wastewater discharge

- Generated $320,000 annual savings in water and sewer costs

- Created 3.2 million gallons concentrated brine for beneficial reuse

- Secured production permits for 40% capacity expansion

Your Path to Food Processing MBR Success

These case studies show MBR technology solving real problems for food processors across different industries and applications. The key to success lies in proper system design that addresses your specific waste characteristics and operational patterns rather than applying generic solutions.

[^1]: Exploring this link will provide insights into zero liquid discharge, its advantages, and its importance in water management.

[^2]: This resource will explain the MBR-RO system's functionality and its role in enhancing wastewater treatment efficiency.