Flat Sheet MBR Membranes: The Smart Alternative to Mitsubishi, Suez & GE

Engineered for Superior Performance and Unmatched Durability. Upgrade your wastewater treatment system and slash operational costs with a proven, reliable solution trusted in over 30 countries.

Call Us

+86 18221094035

chris@shchenmo.com

Address

No. 1188 Jiangyue Road, Minhang District, Shanghai

Production Process

We have more than 10+ years of product production experience, project design experience in more than 30 countries and help equipment debugging and successful operation. Standardized production process to ensure the quality of the diaphragm

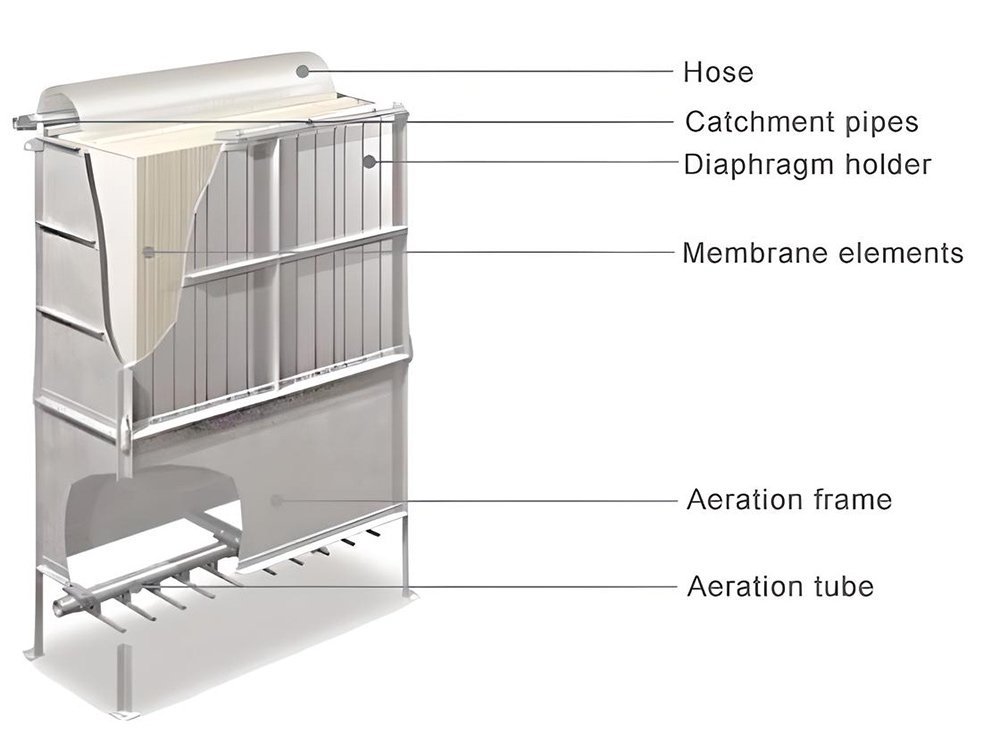

MBR Structure Design

Advanced flat sheet membrane bioreactor structure for optimal water treatment efficiency

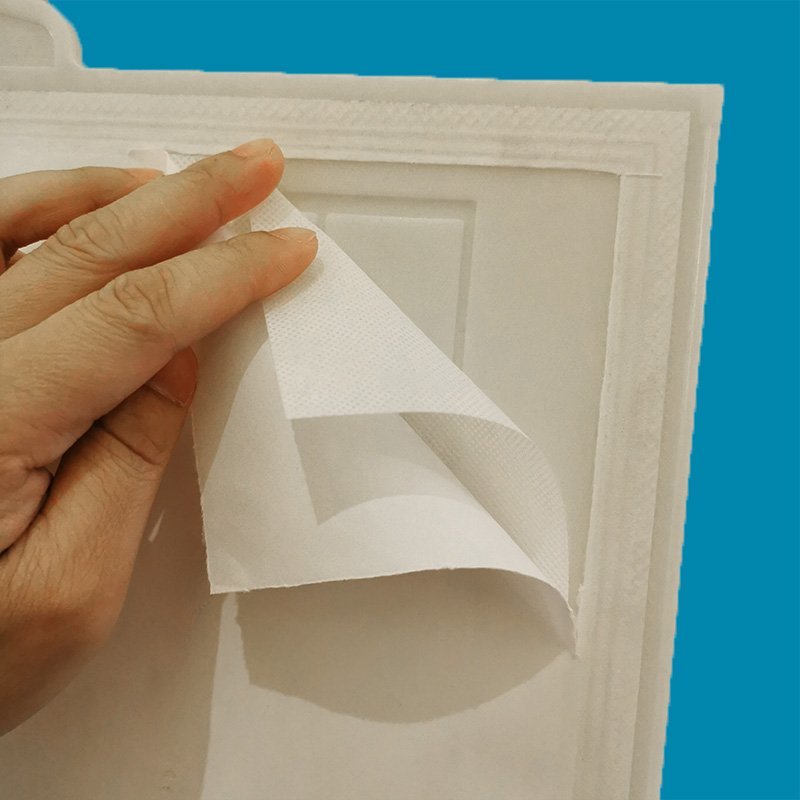

Drying of membrane

Freshly produced membrane, dried before use in the next step

Integration of diaphragm and frame

Seal the edge of the diaphragm in the frame slot, and use hot-melt adhesive, epoxy resin or rubber sealing ring for sealing to prevent leakage.

Storage & Logistics

Modern warehouse facilities ensuring quality preservation and timely delivery

Quality Testing

State-of-the-art testing laboratory ensuring product reliability and performance

Video Demonstration

Watch our equipment in action and see the technology behind our solutions

Ready to Get Started?

Contact us today for equipment quotation and custom project design tailored to your specific requirements

The Global Standard for MBR Technology

With over a decade of dedicated expertise, we don't just sell membranes—we deliver comprehensive wastewater solutions. Our global footprint and proven track record are your guarantee of quality.

By the Numbers - A Global Network of Trust

Years of Specialized Industry Experience

in Annual Global Sales

Countries with Successful Installations

State-of-the-Art Production Facility

Global Service Network

Case Study Spotlight - Proven Success in Demanding Environments

Municipal Wastewater Treatment Plant Upgrade, Russia

Challenge

The existing system from a Tier-1 European brand suffered from frequent fouling and high energy consumption, failing to meet new discharge standards.

Our Solution

We retrofitted the basins with our high-flux flat sheet membrane modules.

The Result

Flat Sheet MBR Structure

MBR flat membrane module is mainly composed of membrane box and aeration box, membrane box is equipped with membrane module, silicone tube, water collection pipe, slot plate, etc., and aeration tube and gas collection box are provided in the aeration box.

Performance Parameters

Remark

The water yield in the above table is the initial filtration flux of the membrane when the suction negative pressure is 10KPa and the temperature is 25 °C, and the water yield will vary greatly under different water quality.

| Model | CM-F-80 | CM-F-100 | CM-F-150 |

|---|---|---|---|

| Effective membrane area (m²) | 0.8 | 1.0 | 1.5 |

| Length × Width × Thickness (mm) | 1000×490×7 | 1250×490×7 | 1750×490×7 |

| Membrane pore size (μm) | 0.2 | ||

| Water production (L/Pcs·d) | 380-560 | 500-620 | 500-720 |

| Aeration volume (L/min·pcs) | ≥10 | ≥11 | ≥12 |

| Film material | PVDF | ||

| Weight (kg) | 3.2 | 3.6 | 5.8 |

| pH Range | 3~12 | ||

| Effluent turbidity (NTU) | <1 | ||

| Effluent suspended solids (SS) | ≤5 | ||

Project Cases

Industrial Water Treatment Project

Municipal Wastewater Treatment

Commercial Water Purification

Advanced MBR System Installation

Why Choose Shanghai CM

We are a company that values customers' satisfaction. We always aim at producing and delivering quality flat sheet mbr that meet all your needs.

With 10+ years of experience, CM is well versed in this field. You can trust them with your needs and expectations.

We are certified; CE and ISO9001 approved

Equipment can be customized according to environmental conditions

We are genuine in all our dealings

Faster delivery cycle

Exhibition

Shanghai CM's 2023-2025 global exhibition live events

Manila, Philippines Mar 22-24, 2023

Jakarta, Indonesia Sep 18-20, 2024

Moscow, Russia Sep 10-12, 2024

Dubai, United Arab Emirates Oct 1-3, 2024

Event Gallery

Highlights from our global exhibitions