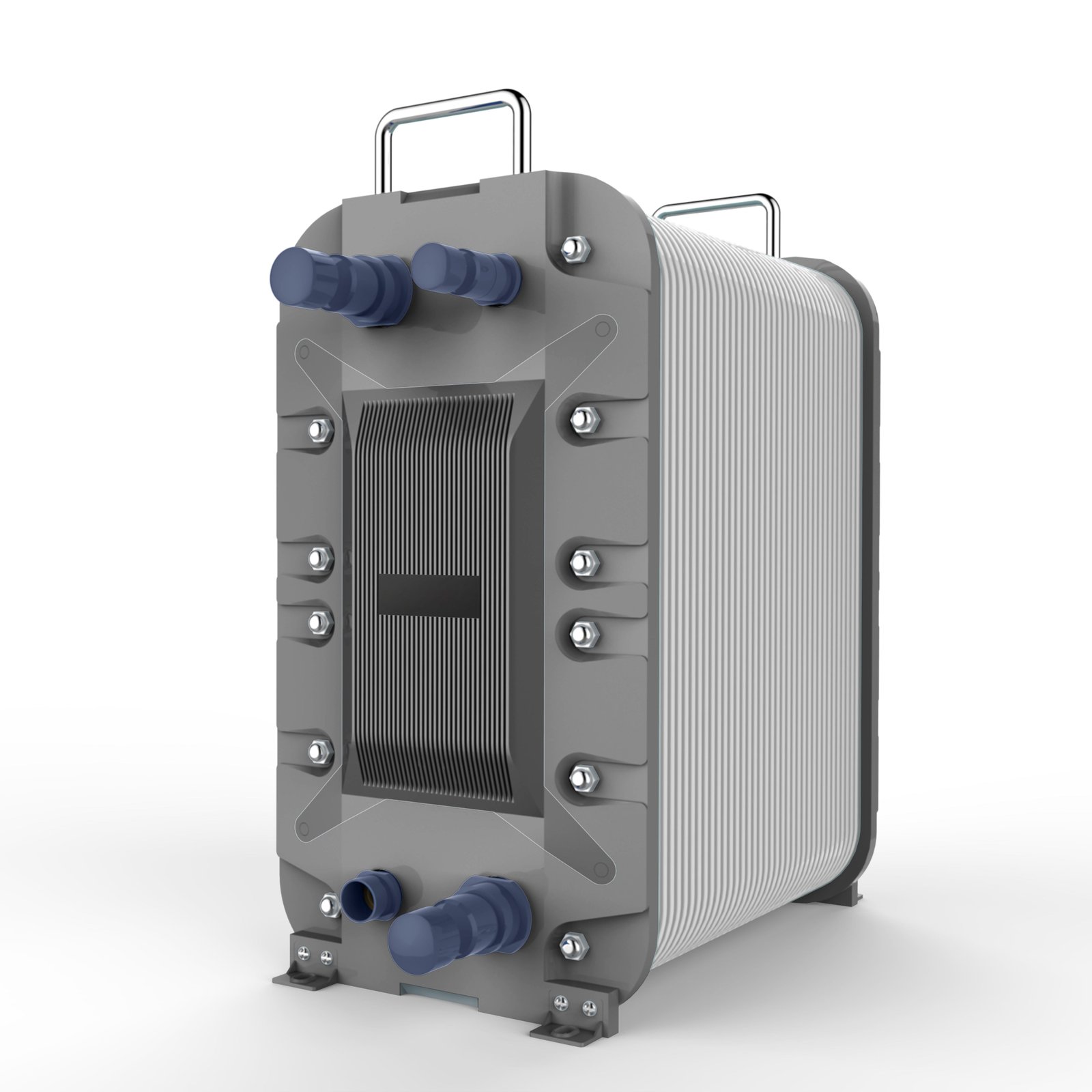

EDI Module

As an economical and practical environmentally friendly ultrapure water treatment solution, continuous electrodeionization technology applies continuous electrodeionization technology, which does not require chemical regeneration and no acid and alkali discharge, and can fully meet the requirements of energy conservation and environmental protection.

Product Features

Our advanced membrane technology delivers superior water purification with reliable performance and minimal maintenance.

Superior Sealing Technology

Double O-rings are used for sealing to ensure that the membrane stack does not leak during operation, providing reliable and consistent performance.

Exceptional Water Quality

The water quality of the produced water is better than that of the mixed bed, and no chemical regeneration is required, ensuring pure results every time.

Continuous Operation

Water is produced continuously with stable quality without fluctuation, eliminating the need for acid or alkali neutralization systems or resin tanks.

Electrical Insulation

Our system features excellent electrical insulation performance, ensuring safety and reliability in all operating conditions.

High Performance Capacity

Can operate continuously at 7 bar (100 psi) and 45°C (113°F), making it suitable for demanding industrial applications.

Maintenance-Free Design

No chemical regeneration required, significantly reducing maintenance costs and environmental impact compared to traditional systems.

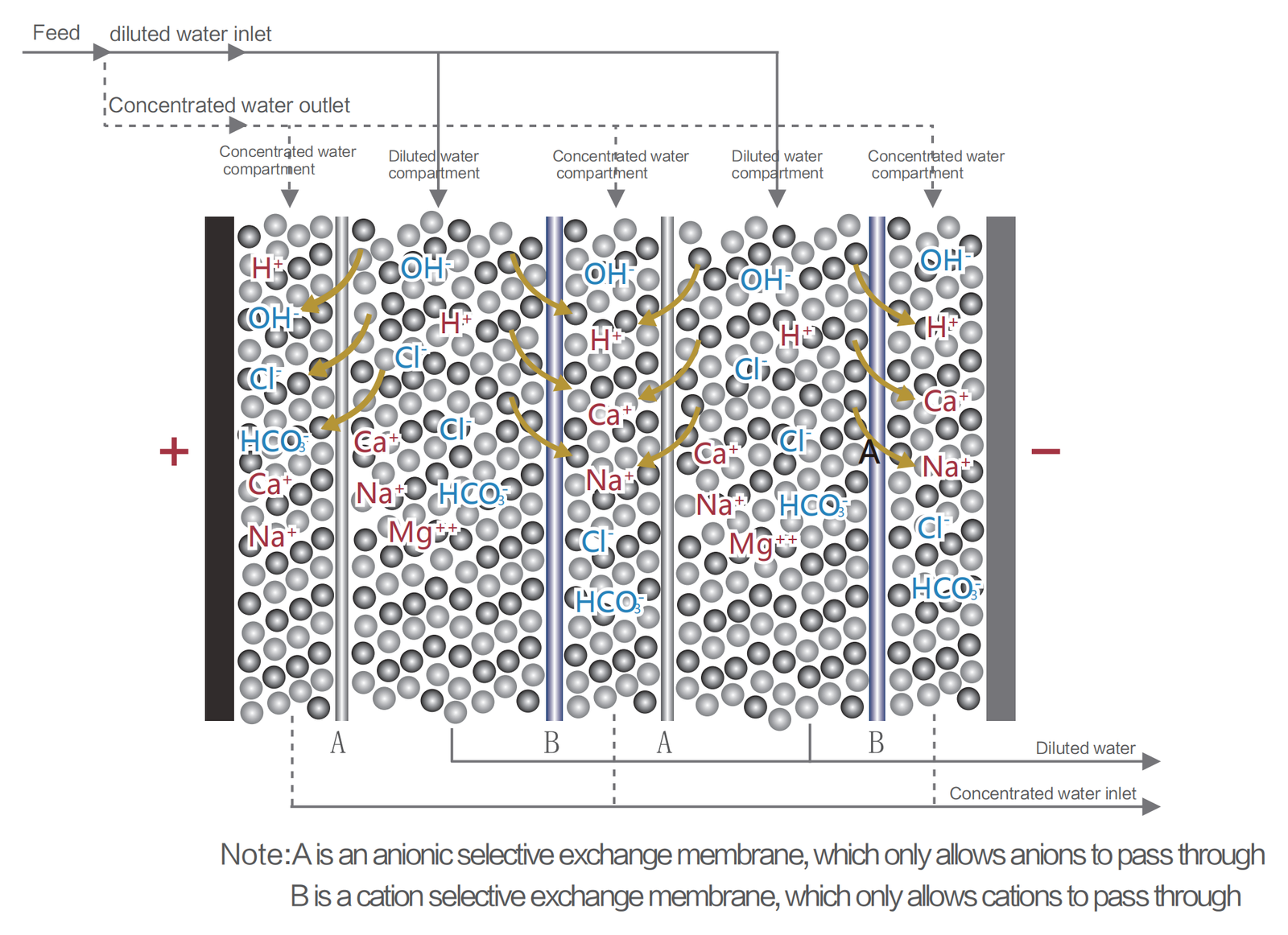

Working Principle of EDI

The working principle of EDI (Electrodeionization) is to drive the ions on the surface of the ion exchange resin to migrate rapidly through the direct current (DC) electric field loaded by the anode (+) and cathode (-) of the EDI membrane block.

The anions/cations in the fresh water chamber selectively pass through the anion/cation exchange membrane and enter the concentrated water chamber.

In a specific area of the fresh water chamber, a large amount of H+ and OH- are generated by the splitting of water. Under the action of the DC electric field, H+ and OH- replace the inorganic salt ions bound to the failed resin to complete the regeneration, achieving continuous and efficient operation.

EDI Membrane Block Schematic

Diagram showing the ion migration process through the EDI membrane with anode (+) and cathode (-) electric field.

Feed Water Specifications

| Feed Water Source | 2RO permeate |

| Feed Water Conductivity | ≤ 10µS/cm |

| Silica (SiO2) | <1 ppm |

| Iron (as Fe, Mn, S) | <0.01 ppm |

| Total Chlorine (as Cl2) | <0.02 ppm |

| Total Hardness (as CaCO3) | <1.0 ppm |

| Dissolved Organics (TOC as C) | <0.5 ppm |

| PH | 4-11 |

| Temperature | 5- 45°C |

| Inlet Pressure | <100 psi(7 bar) |

Operating Parameters

| Recovery | 90-95% |

| Pressure Drop Range at Nominal Flow | 20 - 36 psi(1.4 - 2.5 bar) |

|

Production Water Quality

|

|

| Production Water Resistivity |

Minimum flow rate >17MΩ.cm Nominal Flow >15MΩ.cm Maximum flow >7MΩ.cm |

| Silica (SiO2) Removal | 90-99% (depending on feed conditions) |

Specifications may vary based on system configuration and operating conditions. Please consult with our technical team for detailed information.

Product Specifications

Our DS Series EDI module offer industry-leading performance with various flow capacities to meet your specific requirements.

| Module Number | Nominal Flow (m³/h) | Flow Range (m³/h) | DC Voltage (V) | DC Current (A) | Transport Weight (KG) |

|---|---|---|---|---|---|

| DS05-S | 0.44 | 0.22-0.67 | 0-55 | 0-5 | 55 |

| DS10-S | 1 | 0.55-1.65 | 0-135 | 0-5 | 71 |

| DS20-S | 2 | 1.0-3.1 | 0-240 | 0-5 | 94 |

| DS30-S | 3.3 | 1.7-5.1 | 0-320 | 0-5 | 124 |

| DS50-S | 5 | 2.55-7.7 | 0-400 | 0-5 | 170 |

Technical Support

Need help selecting the right model for your application? Our technical team is available to assist you with detailed specifications and customized solutions.

Download Resources

Access detailed product datasheets, installation guides, and performance curves for our DS Series solar water pumps.

Download PDF* Specifications may vary slightly based on installation conditions and environmental factors. Please consult with our technical team for the most accurate information for your specific application.

Application Cases

Our water treatment solutions have been successfully implemented across various industries.

Energy and Chemical Industry Solution

2250 m³/H

≥16 MΩ·cm

100V/2.0A

Ningxia, China

Thermal Power Plant Solution

1800 m³/H

≥16 MΩ·cm

120V/2.0A

Lianyungang, China

CONTACT SHANGHAI CM

We'd love to hear from you. Please fill out the form or contact us directly using the information below.

Send Us a Message

Our Growth Journey

2009

Started manufacturing ultrafiltration membranes in Qingpu District, Shanghai.

2013

Added MBR production line and received CE and ISO 9001:2015 certifications.

2019

Established Shanghai CM Environmental Technology Co., Ltd. for overseas markets.

2023-2026

Expanded to 60+ countries with over 1,000 global customers and partners.