SHANGHAI CM

SHANGHAI CM

SHANGHAI CM

SHANGHAI CM

Whether you are replacing an old project or designing a new project, we can provide it for you based on our rich experience. We have professional sales staff to connect with you to solve all your problems from purchasing to using the MBR membrane.

We can provide flat membranes, hollow fiber membranes and sewage treatment components, including sewage treatment solution design and subsequent maintenance guidance

Custom wastewater treatment solutions tailored to your specific needs

Professional installation and commissioning services

Ongoing maintenance support and technical guidance

Comprehensive comparison between Hollow Fiber and Flat Sheet Membrane Bioreactor (MBR) technologies for wastewater treatment applications

Hollow fiber configurations are designed for higher fluxes, operated at lower concentrations, cleaned more often and protected by stricter pre-treatment compared to flat sheet systems. The filterability of activated sludge from municipal MBRs is superior to industrial MBRs and remains independent of membrane configuration.

| Comparison Factor | Flat Sheet MBR | Hollow Fiber MBR |

|---|---|---|

| Usage Rate |

Around 15%

|

Around 85%

|

| Material |

PVDF

|

PVDF

|

| Flux Range | 10L/m²/h ~ 40L/m²/h | 10L/m²/h ~ 40L/m²/h |

| Pre-processing Requirements |

No Special Requirements

|

Hair Removal Required

|

| Packing Density |

Toray TMR140-100s

140m² needs 2.756 m³

|

Dow FLEXELL

80m² needs 0.7056 m³

2x Higher Density

|

| Pollution Recovery Method |

Air Scrubbing

Chemical Cleaning

|

Backwash

Air Scrub

Enhanced Backwash

Chemical Cleaning

|

| Operational Risk |

Membrane Rupture Risk

"Fat belly" phenomenon

|

Fiber Breakage Risk

Minimized with TIP process

|

| Self-healing |

No Self-healing

|

Self-healing Function

|

| Component Structure |

Large Modular

Requires lifting equipment

|

Single Element

Easy single-person maintenance

|

| Energy Consumption |

Air-water ratio 30:1

High gas consumption

|

Gas-water ratio 3:1~5:1

Low energy consumption

|

| Chemical Wash |

Manual + Chemical

Labor intensive

|

Chemical Immersion

Automated, single operator

|

PVDF's superior oxidation resistance compared to other materials (such as PE) makes it the mainstream material for MBR membranes in sewage treatment and reuse applications.

Backwashing is the most ideal pollution recovery method for the membrane industry. The inability to backwash is the biggest defect of flat membranes, leading to shortened chemical cleaning cycles.

Membrane Bioreactors (MBRs) can be broadly defined as a system that combines wastewater biodegradation with membrane filtration. They have proven to be very effective in removing organic and inorganic pollutants as well as biological entities from wastewater.

There are many types of MBR such as tubular, plate and hollow fiber. Among them, hollow fiber PVDF material has been proven to be the most reasonable in price and good in performance. The membranes used had pore sizes ranging from 0.01 to 0.4 µm.

Good control of biological activity with automatic STP system operation and reduced labor costs

Produces effluent free of bacteria and pathogens with superior water quality

Smaller plant size with lower space requirements due to higher MLSS and short HRT

Capable of handling higher organic loading rates efficiently

Currently, MBR is widely applied to all types of wastewater, including water recycling in buildings, wastewater treatment for small communities, industrial wastewater treatment, landfill leachate treatment, and agricultural wastewater processing.

MBR systems were initially used for municipal wastewater treatment, primarily in the area of water reuse and recycling. Compactness, production of reusable water, and trouble-free operation made the MBR an ideal process for recycling municipal wastewater in water and space limited environments.

High organic loadings and very specific and difficult to treat compounds are two major characteristics of industrial waste streams that render alternative treatment techniques such as the MBR desirable. Since traditionally wastewater with high COD content was treated under anaerobic conditions, initial attempts of MBR applications for industrial wastewater were in the field of anaerobic treatment.

Also effective removal of nitrates, herbicides, pesticides, and endocrine disrupting compounds may be achieved by MBRs.

In addition to municipal and industrial wastewater treatment, MBRs have been utilized in a number of other areas. One such area is the treatment of landfill leachates. Landfill leachates usually contain high concentrations of organic and inorganic compounds.

MBR systems have been successfully utilized with an additional treatment step for inorganics and heavy metal removal, such as Ultra Filtration and reverse osmosis (RO). Several industrial scale plants, combining a MBR, Ultra filtration and a reverse osmosis system, are presently operated.

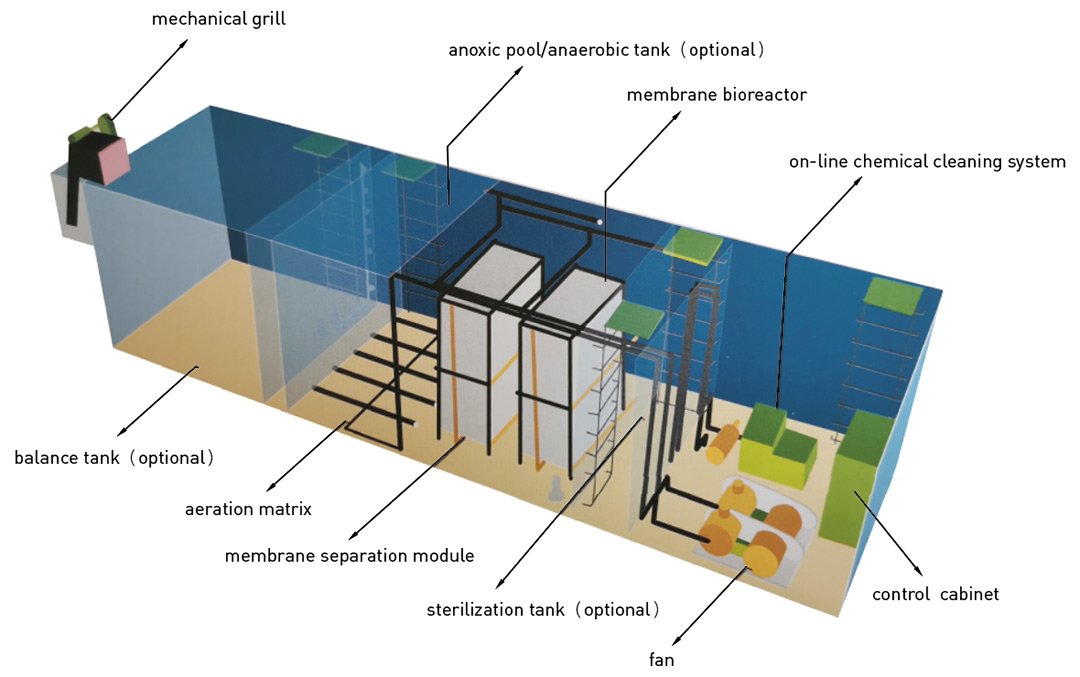

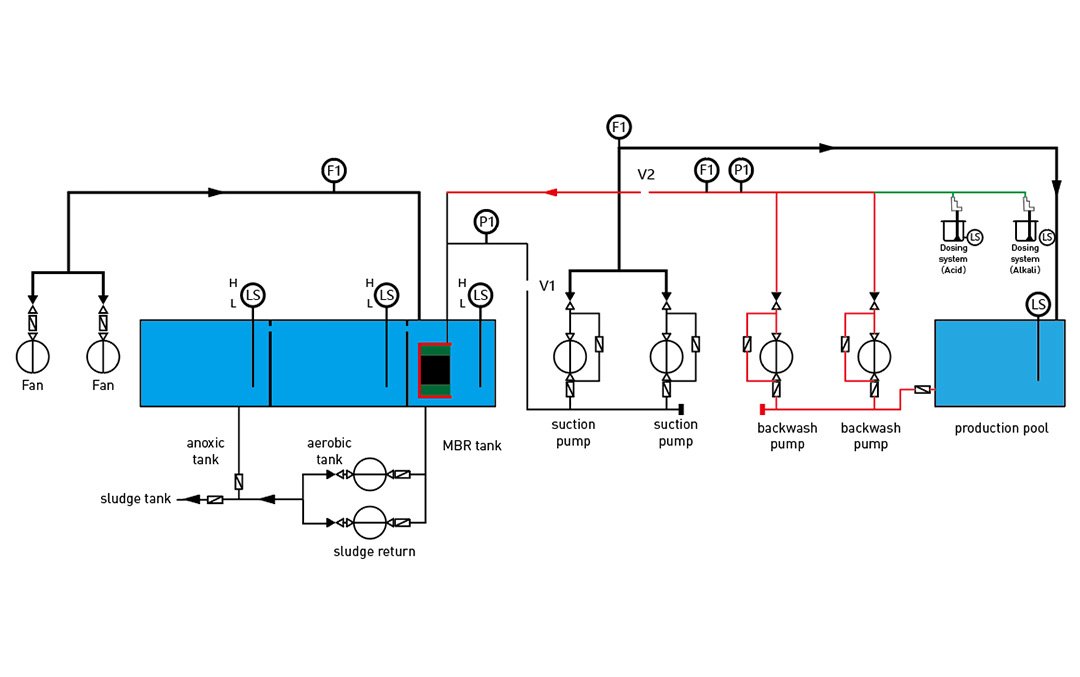

Advanced membrane bioreactor technology for efficient wastewater treatment with compact design and superior performance

Our state-of-the-art MBR integrated equipment combines biological treatment with membrane filtration technology, delivering exceptional water quality while maintaining compact footprint and energy efficiency.

Combines biological treatment with membrane filtration for superior effluent quality

Intelligent PLC control system with remote monitoring capabilities

Low energy consumption with minimal environmental impact

Leading manufacturer of water treatment membranes and systems since 2009, serving over 60 countries worldwide.

© 2024 Shanghai CM Environmental Technology Co., Ltd. All rights reserved.