Choosing the wrong reverse osmosis membrane can cost you thousands in downtime and poor water quality. Your production depends on clean water. The right membrane saves money and prevents headaches.

The best RO membrane depends on your water quality, flow rate requirements, and specific contaminants. Consider TDS levels, operating pressure, temperature range, and membrane material compatibility with your system.

I learned this lesson the hard way when our mold cooling system started producing defective parts. The water quality was inconsistent. After switching to the right membrane, our rejection rates dropped by 80%. Let me share what I discovered about making the right choice.

What Are the Main Types of RO Membranes Available?

Different membrane types serve different purposes. Thin film composite membranes work best for most applications. Cellulose acetate membranes handle chlorine better but have shorter lifespans.

Thin film composite (TFC) membranes offer superior salt rejection rates and durability. Cellulose acetate (CA) membranes resist chlorine damage but require lower pH levels and have reduced lifespan compared to TFC options.

Understanding Membrane Materials and Performance

The membrane material determines everything. TFC membranes use polyamide as the active layer. This gives them excellent salt rejection. They can remove up to 99.5% of dissolved solids. But they cannot handle chlorine. Even small amounts damage them permanently.

CA membranes work differently. They use cellulose acetate polymer. This material handles chlorine well. You can use chlorinated water without pre-treatment. But the trade-off is performance. Salt rejection rates stay around 95-98%. The lifespan is also shorter. Most CA membranes last 1-2 years. TFC membranes can last 3-5 years with proper care.

I always recommend TFC membranes for manufacturing. The higher upfront cost pays off. Better water quality means fewer problems downstream. Your equipment lasts longer. Product quality stays consistent.

| Membrane Type | Salt Rejection | Chlorine Tolerance | Lifespan | Best Use |

|---|---|---|---|---|

| TFC | 99-99.5% | Poor | 3-5 years | High purity needs |

| CA | 95-98% | Excellent | 1-2 years | Chlorinated water |

How Do You Determine the Right Membrane Size and Configuration?

Size matters more than people think. Wrong sizing leads to poor performance or wasted money. You need to match membrane area to your flow requirements. Configuration affects space usage and maintenance access.

Calculate your daily water needs first. Add 20% safety margin for peak demand. Choose membrane size based on flux rates and operating pressure. Consider spiral wound for high flow, hollow fiber for compact installations.

Calculating Your Water Requirements

Start with actual usage data. Don't guess. Measure water consumption for one week. Include all processes that need treated water. Add cleaning cycles and backwash requirements. Peak demand usually happens during shift changes.

Flow rate determines membrane size. Standard residential membranes produce 50-100 gallons per day. Commercial systems need 200-10,000 gallons per day. Industrial applications can require 50,000+ gallons daily.

Pressure affects performance. Most RO membranes work best at 150-300 psi. Higher pressure increases flow but reduces membrane life. Lower pressure gives poor rejection rates. Match your pump capacity to membrane requirements.

I made this mistake early in my career. We installed oversized membranes to "be safe." The system ran at low recovery rates. Water waste was enormous. Energy costs went through the roof. Right-sizing saved us 40% on operating costs.

What Water Quality Parameters Should You Test Before Selection?

Testing reveals everything about your water. Skip this step and you will choose wrong. TDS, pH, temperature, and specific contaminants all matter. Each parameter affects membrane selection and system design.

Test total dissolved solids, pH levels, chlorine content, hardness, and iron levels. Also check for silica, bacteria, and organic compounds. These results determine pretreatment needs and membrane compatibility.

Key Parameters That Affect Membrane Performance

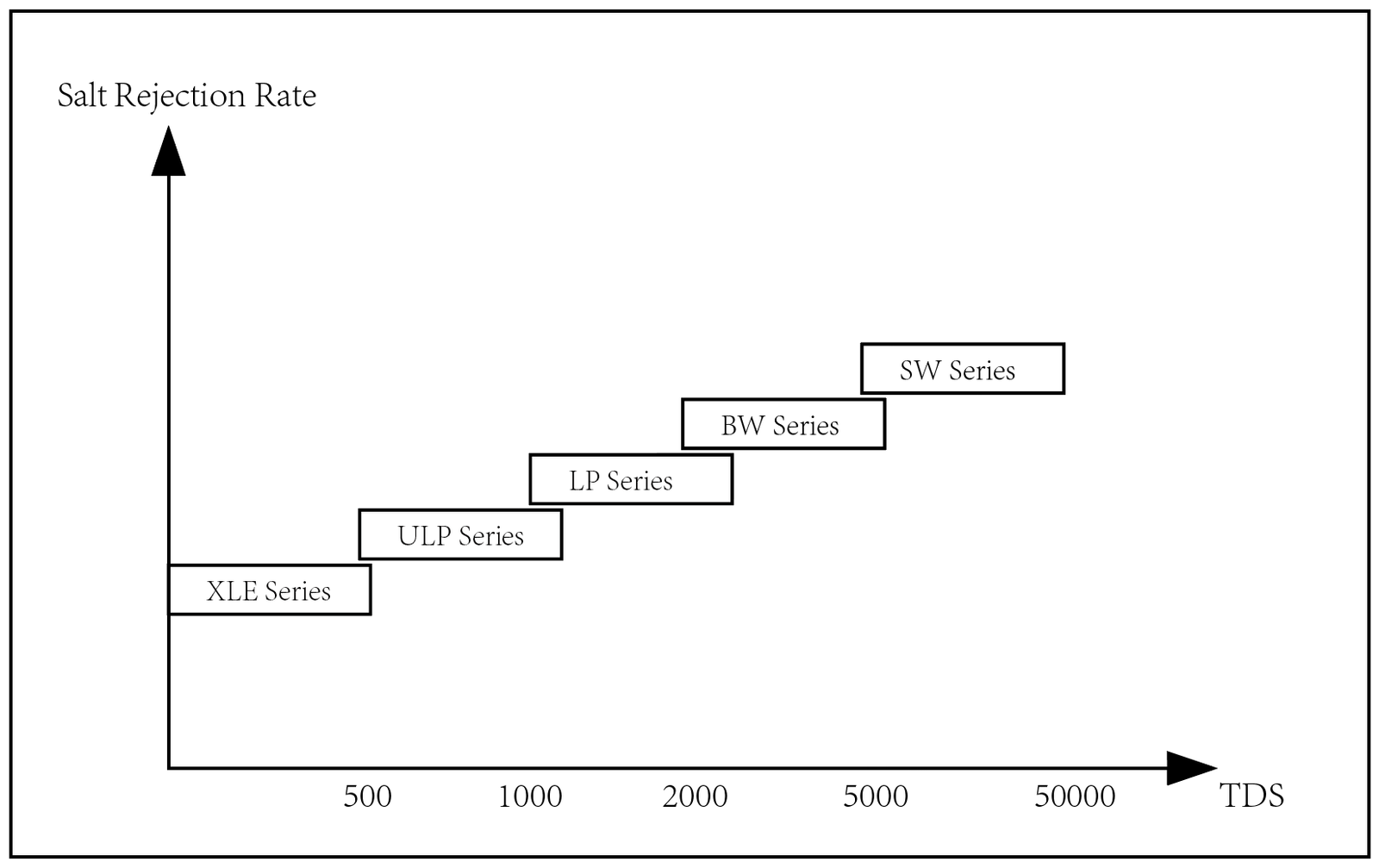

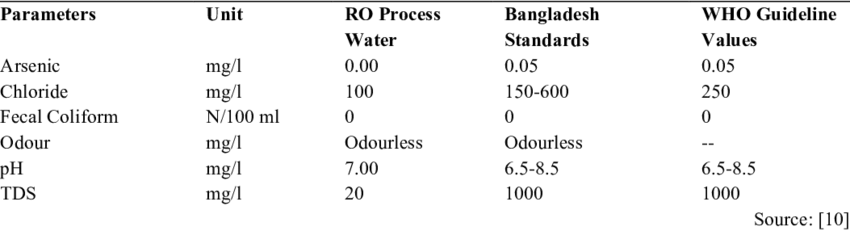

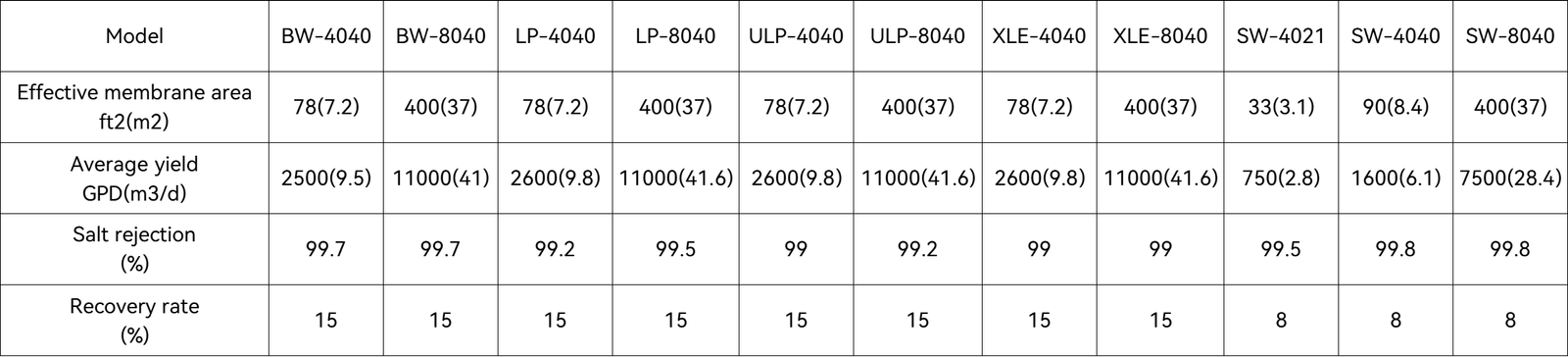

TDS tells you salt concentration. Higher TDS needs more pressure and reduces membrane life. Most RO membranes handle up to 2000 ppm TDS well. Above that, you need specialized high-rejection membranes.

pH affects membrane stability. TFC membranes work best between pH 4-11. CA membranes need pH 4-6.5. Wrong pH causes membrane degradation. Use pH adjustment chemicals if needed.

Temperature changes performance. Higher temperature increases flux but reduces salt rejection. Most membranes work best at 77°F (25°C). Every 10°F increase doubles biological growth risk.

Chlorine destroys TFC membranes instantly. Even 0.1 ppm causes damage. Use carbon filtration or sodium bisulfite injection for dechlorination. CA membranes handle up to 1 ppm chlorine safely.

Hardness causes scaling. Calcium and magnesium precipitate on membrane surfaces. This reduces flow and increases pressure. Use water softening or antiscalant chemicals for hardness above 100 ppm.

Iron fouls membranes quickly. Oxidized iron creates a sticky layer. This layer traps other contaminants. Keep iron below 0.05 ppm. Use iron removal filters if needed.

How Do Operating Conditions Affect Membrane Choice?

Your system conditions limit membrane options. Pressure, temperature, and pH ranges vary by location. Some membranes work better in specific conditions. Match membrane specs to your operating envelope.

Consider maximum operating pressure, temperature range, pH tolerance, and cleaning chemical compatibility[^1]. Also factor in recovery rate requirements[^2] and concentrate disposal limitations for optimal membrane selection.

Pressure and Flow Rate Considerations

Pressure drives the separation process. Higher pressure means better rejection but shorter membrane life. Most systems operate at 150-250 psi. High-pressure membranes can handle 400+ psi for very high TDS water.

Recovery rate affects concentrate quality. Higher recovery means more concentrated waste stream. Standard systems run 75% recovery. Specialized systems can achieve 85-90% recovery with proper design.

Flow rate per membrane element matters. Too high flow causes pressure drop and poor rejection. Too low flow allows concentration polarization. Follow manufacturer guidelines for optimal flux rates.

I learned this during a retrofit project. We pushed flow rates 50% above recommendations. Initial performance looked great. But after six months, membranes started failing. Scaling became a major problem. We had to replace the entire membrane set.

What Maintenance Requirements Should You Consider?

Maintenance determines total cost of ownership. Some membranes need daily attention. Others run months between cleanings. Consider your staff capabilities and downtime tolerance when choosing.

Evaluate cleaning frequency requirements, chemical compatibility, replacement intervals, and monitoring needs. Factor in staff training requirements and spare parts availability for long-term cost planning.

Cleaning and Replacement Schedules

Cleaning frequency depends on feed water quality. Clean water systems need monthly cleaning. Dirty water systems may need weekly attention. Use normalized pressure drop and flux decline to trigger cleanings.

Chemical cleaning requires compatible membranes. Acidic cleaners remove scale. Alkaline cleaners remove organics and biofilms. Some membranes cannot handle certain chemicals. Check compatibility charts before selection.

Replacement timing affects system performance. Don't wait for complete failure. Replace membranes when rejection drops below acceptable levels. Typical replacement intervals range from 2-5 years depending on conditions.

Monitoring prevents surprises. Track pressure, flow, and conductivity daily. Plot trends to predict maintenance needs. Sudden changes indicate problems. Early detection saves money and prevents system damage.

The right reverse osmosis membrane balances performance, cost, and maintenance requirements. Test your water, understand your needs, and choose accordingly for optimal results.

[^1]: Discover guidelines for selecting and testing cleaning chemicals to ensure membrane compatibility, extend membrane life, and maintain filtration efficiency.

[^2]: Learn how optimizing recovery rates improves efficiency, reduces waste, and ensures reliability in membrane filtration systems.