Struggling to understand nanofiltration? Confused by its place in water treatment? This post will explain what you need to know.

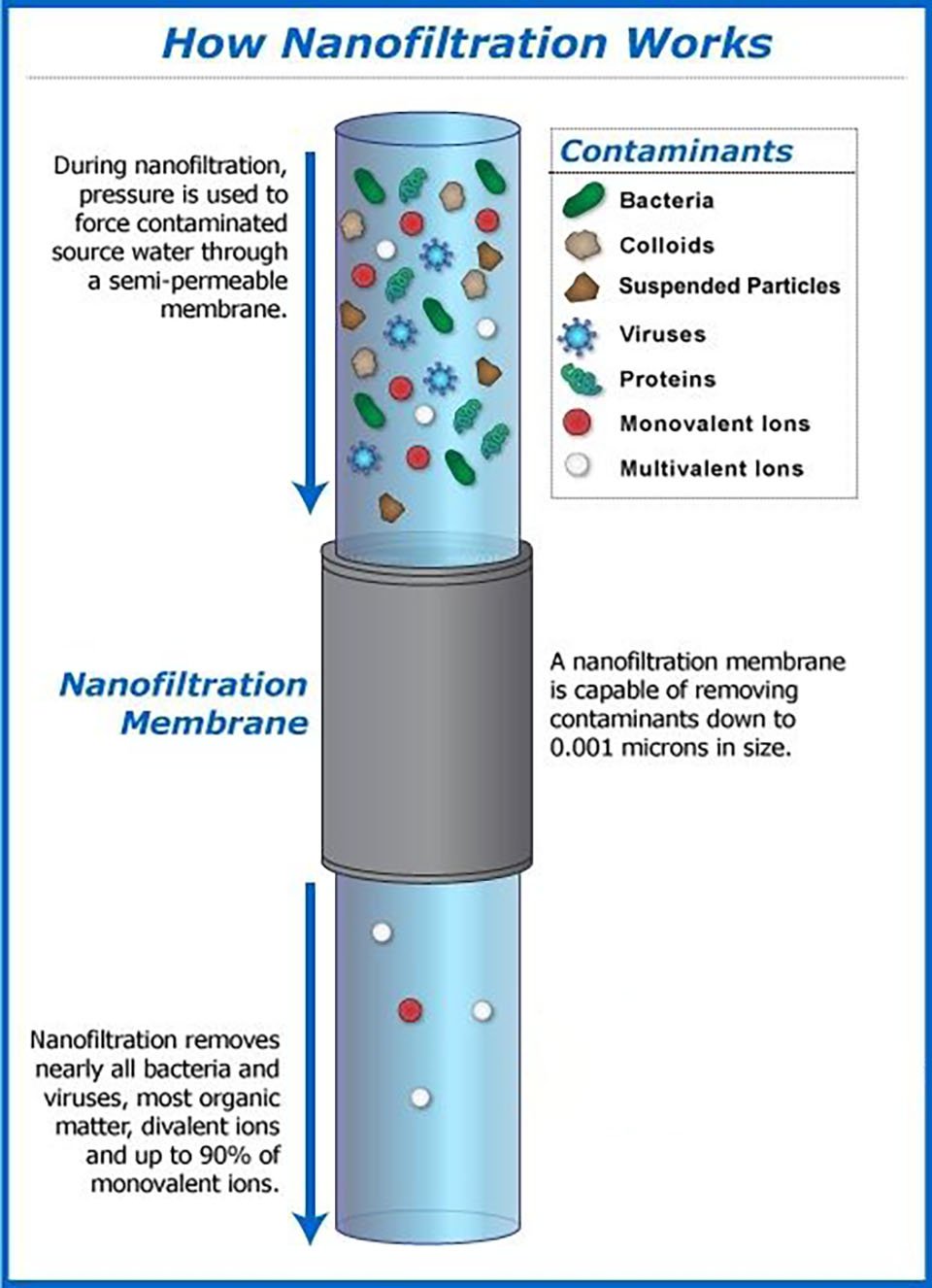

A nanofiltration (NF) membrane is a type of filter. It removes very small particles from water. These include some salts, organic molecules, and color. It fits between ultrafiltration and reverse osmosis in terms of pore size.

You might be wondering how this type of membrane really works and where it fits in. It’s a fascinating piece of technology, and I’ve seen it solve some tricky water problems over my twelve years in the field. Let’s explore it more. We will look at how it compares to other membranes, its downsides, its uses, and when it’s the best choice. Keep reading, and you’ll get a much clearer picture.

What is the difference between NF and RO membrane?

Confused by NF and RO differences? Worried you might pick the wrong, more expensive one? Let's clearly outline what sets them apart.

Nanofiltration (NF) membranes have slightly larger pores than Reverse Osmosis (RO) membranes. This means NF allows some smaller salts to pass through. RO rejects nearly all salts. NF also works at lower pressures.

When I first started in water treatment, the distinction between Nanofiltration (NF) and Reverse Osmosis (RO) membranes seemed a bit fuzzy. But over the years, working on projects from municipal water to complex industrial wastewater, I've learned their differences are crucial. Understanding these differences helps choose the right tool for the job and save clients a lot of headaches and money.

Pore Size and Molecular Weight Cut-Off (MWCO)

The most basic difference is the size of the "holes" or pores in the membrane.

- NF Membranes: These typically have a pore size of about 0.001 to 0.01 micrometers. Their Molecular Weight Cut-Off (MWCO) usually ranges from 200 to 1000 Daltons (Da). This means they can block molecules larger than this MWCO.

- RO Membranes: These are much tighter. Their pores are around 0.0001 micrometers. The MWCO is generally less than 100 Daltons. This allows them to block almost everything except water molecules.

Think of it like a sieve. An NF membrane is like a sieve with slightly larger holes than an RO membrane. This difference in pore size directly affects what each membrane can remove. For example, NF is great for selectively removing larger organic molecules or certain ions, while RO aims for almost total purification. I remember a project for a beverage company. They wanted to concentrate fruit juice. An RO membrane would have removed too many of the small flavor compounds. An NF membrane, with its specific MWCO, was perfect for removing water while retaining those essential flavor profiles. This ability to be selective is a key strength of NF. My insight here is that nanofiltration can selectively retain target components based on molecular weight differences (e.g., tea polyphenols around 300-500 Da, caffeine around 194 Da), while removing small molecule impurities (like water, inorganic salts), avoiding the retention loss of low molecular weight active ingredients by RO membranes.

Salt Rejection

This is a major point of difference.

- NF Membranes: NF membranes are often called "softening membranes" because they are very good at rejecting divalent ions (ions with a +2 or -2 charge) like calcium (Ca²⁺) and magnesium (Mg²⁺), which cause water hardness. They are less effective at rejecting monovalent ions (ions with a +1 or -1 charge) like sodium (Na⁺) and chloride (Cl⁻). Typically, NF might reject 80-98% of divalent ions but only 20-80% of monovalent ions, depending on the specific membrane and operating conditions. One of my key insights is that NF membranes have a rejection rate of >95% for divalent heavy metal ions (like Cu²⁺, Ni²⁺) while allowing monovalent ions (like Na⁺) to pass through. This makes them more suitable for pre-treating high-salinity wastewater compared to RO. I saw this firsthand at a metal plating facility. We used NF to remove copper and nickel before further treatment. The NF allowed most of the sodium chloride to pass, which reduced the load on the downstream RO system designed for final polishing.

- RO Membranes: RO membranes are designed to reject almost all ions, typically >99% for both monovalent and divalent ions. This is why RO is used for desalination (making fresh water from seawater) or producing highly purified water for industrial processes.

The mechanism for ion rejection is also different. While size exclusion plays a part, Donnan exclusion (charge-based repulsion) is very significant for NF membranes, especially in how they selectively pass monovalent ions while rejecting divalent ones.

Operating Pressure

This difference has big implications for energy use and cost.

- NF Membranes: They operate at lower pressures than RO systems. Typical operating pressures for NF range from 50 to 250 psi (3.5 to 17 bar).

- RO Membranes: They require much higher pressures to overcome the osmotic pressure of the feed water, especially with high salt concentrations. Pressures can range from 100 psi for brackish water to over 1000 psi (70 bar) for seawater.

Lower operating pressure for NF means lower energy consumption. This can make a big difference in the overall operating cost of a water treatment plant. I recall a project where we were deciding between NF and RO for reducing Total Dissolved Solids (TDS) in well water. The client didn't need ultrapure water, just a reduction in hardness and some TDS. Choosing NF saved them significantly on their energy bills.

Selectivity for Organic Molecules

Both NF and RO remove organic molecules, but their approach and effectiveness differ.

- NF Membranes: Due to their larger pore size and MWCO, NF membranes are good at removing larger organic molecules like pesticides, herbicides, and natural organic matter (NOM), which can be precursors to disinfection by-products. They can be more selective, allowing smaller, sometimes desirable, organic molecules to pass.

- RO Membranes: RO membranes, with their very tight pores, remove a broader range of organic molecules, including many smaller ones. This is excellent for producing high-purity water. However, as I mentioned with the fruit juice example, this can be a disadvantage if you want to retain certain small organic compounds.

Comparison Table: NF vs. RO

| Feature | Nanofiltration (NF) | Reverse Osmosis (RO) |

|---|---|---|

| Pore Size | ~0.001 - 0.01 µm | ~0.0001 µm |

| MWCO | 200 - 1000 Da | < 100 Da |

| Divalent Ion Rejection | High (e.g., Ca²⁺, Mg²⁺, SO₄²⁻ >90%) | Very High (>99%) |

| Monovalent Ion Rejection | Moderate (e.g., Na⁺, Cl⁻ 20-80%) | Very High (>99%) |

| Operating Pressure | Lower (50-250 psi / 3.5-17 bar) | Higher (100-1000+ psi / 7-70+ bar) |

| Energy Consumption | Lower | Higher |

| Primary Use | Softening, color removal, specific organic removal, partial demineralization | Desalination, ultrapure water, full demineralization |

| Fouling Potential | Can be susceptible, especially to scaling if not managed | Also susceptible, requires good pre-treatment |

| Selectivity | Higher for specific solutes | Lower (rejects almost everything) |

Understanding these differences is key. It's not about which membrane is "better" overall, but which is better for a specific application. As an engineer, my job is to analyze the water, understand the treatment goals, and then select the most effective and economical membrane technology. Sometimes it’s NF, sometimes it’s RO, and sometimes it’s a combination. For instance, using NF as a pre-treatment for RO can protect the RO membranes from scaling by removing hardness ions, extending their life and improving overall system efficiency.

What are the disadvantages of nanofiltration?

Is nanofiltration a perfect solution? Not always. Overlooking its potential drawbacks can lead to unexpected problems and costs. Let's discuss its limitations.

Nanofiltration membranes can be prone to fouling if the feed water isn't properly pre-treated. They also don't remove all dissolved salts like RO does. Their selectivity, while often a benefit, can sometimes be a disadvantage if complete purification is the goal.

While nanofiltration is a powerful tool in my water treatment arsenal, it's not without its challenges. I've seen projects where NF was an excellent fit, but also situations where its limitations became apparent. It's important to go in with open eyes.

Susceptibility to Fouling

This is probably the most common issue with NF membranes, much like other membrane processes. Fouling occurs when suspended solids, organic matter, biological growth, or precipitated salts accumulate on the membrane surface or within its pores.

-

Types of Fouling:

- Particulate/Colloidal Fouling: Caused by silt, clay, or other fine suspended particles.

- Organic Fouling: Due to natural organic matter (NOM), oils, or greases. NOM can be particularly tricky with NF.

- Biofouling: Growth of bacteria and other microorganisms on the membrane surface, forming a biofilm. This was a nightmare for a food processing plant I once helped; their existing NF system was constantly underperforming due to biofilm. We had to implement a much more rigorous pre-treatment and cleaning regime.

- Scaling: Precipitation of sparingly soluble inorganic salts (like calcium carbonate, calcium sulfate, or silica) when their concentration exceeds their solubility limit near the membrane surface. This is common if NF is used for softening without proper anti-scalant dosing or pH adjustment.

-

Consequences of Fouling:

- Flux Decline: The rate of water passing through the membrane decreases.

- Increased Transmembrane Pressure (TMP): More pressure is needed to push water through, leading to higher energy costs.

- Reduced Rejection: Sometimes, fouling can compromise the membrane's ability to remove contaminants.

- Shorter Membrane Life: Frequent or harsh cleaning can degrade the membrane material.

- Increased Cleaning Frequency: This means more downtime, chemical costs, and labor.

Proper pre-treatment is absolutely essential to minimize fouling. This can include conventional filtration, microfiltration (MF), or ultrafiltration (UF) upstream of the NF system.

Incomplete Salt Removal

While NF's ability to selectively remove divalent ions and let most monovalent ions pass is often an advantage (e.g., for softening without complete demineralization), it becomes a disadvantage when very low TDS water is required.

- If the goal is to produce high-purity water for applications like boiler feed, semiconductor manufacturing, or certain pharmaceutical processes, NF alone won't cut it. You’d need RO or ion exchange, possibly in combination.

- The permeate from an NF system will still contain a significant amount of monovalent salts (like NaCl). If this level of TDS is unacceptable for the intended use, then NF is not the right choice for demineralization. I remember a client who initially thought NF would be enough for their process water, but the remaining chloride levels were still too high and caused corrosion issues. We had to add an RO stage after the NF.

Selectivity Limitations and Passage of Small Uncharged Molecules

The selectivity of NF membranes, while a key feature, isn't always perfectly sharp.

- Some small, uncharged organic molecules with a molecular weight below the membrane's MWCO might pass through. This can be an issue if these molecules are undesirable contaminants.

- The rejection of specific ions or molecules can also be influenced by feed water chemistry (pH, ionic strength, presence of other compounds), which can sometimes lead to unexpected performance. For instance, the rejection of boron, a common concern in irrigation water, can be quite variable with NF membranes and is highly pH-dependent.

Chemical Sensitivity and Degradation

NF membranes, typically made from thin-film composite polyamide materials, can be sensitive to certain chemicals.

- Chlorine and Oxidizers: Most polyamide NF membranes have very low tolerance to free chlorine (typically <0.1 ppm). Exposure to chlorine can irreversibly damage the membrane, leading to increased salt passage and reduced performance. This means that if chlorination is used for disinfection upstream, thorough dechlorination (e.g., with sodium metabisulfite) is critical before the water reaches the NF membranes. I’ve seen expensive membrane replacements needed because of accidental chlorine exposure.

- pH Range: NF membranes operate best within a specific pH range (usually around pH 3-10, though this varies by membrane type). Operating outside this range for extended periods can cause hydrolysis or degradation of the membrane material.

- Temperature Limits: There are also maximum operating temperature limits that must be respected to prevent membrane damage.

Concentrate (Reject) Stream Management

Like all membrane separation processes, NF produces two streams: the purified permeate and a concentrated reject stream. This reject stream contains all the removed contaminants at higher concentrations.

- Disposal Challenges: Disposing of this concentrate can be an environmental and economic challenge. Options include discharge to a sewer (if permitted), evaporation ponds (in arid areas), deep well injection, or further treatment to recover water or valuable components. The cost and feasibility of concentrate disposal must be factored into the overall viability of an NF project.

- Volume: The volume of concentrate can be significant, typically ranging from 15% to 50% of the feed water flow, depending on the desired recovery rate and feed water quality.

Pressure Requirements (Though Lower than RO)

While NF operates at lower pressures than RO, it still requires higher pressures than MF or UF. This means more robust pumps and piping are needed, and energy consumption, while less than RO, is still a factor to consider, especially for large-scale applications.

Cost Considerations

- Membrane Replacement: NF membranes have a finite lifespan (typically 3-7 years, depending on application and operation) and will eventually need replacement, which is a significant capital expense.

- Pre-treatment Costs: The need for effective pre-treatment adds to the capital and operational costs of an NF system.

- Cleaning Chemicals: Regular cleaning requires chemicals, which also contribute to operational expenses.

Despite these disadvantages, NF remains a very useful technology. The key is to be aware of these limitations and to design and operate the system appropriately. Proper engineering, including thorough feed water analysis, pilot testing for challenging waters, robust pre-treatment, and a well-planned operational and maintenance strategy, can mitigate many of these potential downsides. As a father of a 7-year-old, I always think about the long-term impact and sustainability of any solution, and that includes managing the drawbacks effectively.

What is the use of nanofiltration membrane?

Wondering where NF membranes make a real impact? Concerned you might be missing out on their versatile applications? Let's explore the many practical uses of this technology.

Nanofiltration membranes are widely used for water softening, removing color, and reducing specific dissolved solids. They are also vital in the food, dairy, pharmaceutical, and wastewater treatment industries for specialized separations.

%(Industrial application of nanofiltration)(/wp-content/uploads/replace/69a0e369000b9a76c8fe1b9d5d2e6162.png "NF in Industry")

Over my twelve years in water treatment, I've seen nanofiltration step up in a surprising variety of situations. It's not just about making water softer; its unique selective separation capabilities open doors in many industries. Let me share some of the key areas where NF truly shines.

1. Drinking Water Treatment

This is a major application area for NF.

- Water Softening: NF membranes are excellent at removing divalent ions like calcium (Ca²⁺) and magnesium (Mg²⁺), which are responsible for water hardness. This is a great alternative to traditional ion exchange softening, especially for larger municipal systems, as NF doesn't require salt regeneration and doesn't increase the sodium content of the treated water as much. I’ve designed NF systems for communities struggling with very hard well water, and the improvement in water quality for residents was immediate and noticeable – no more scale buildup in pipes and appliances!

- Removal of Disinfection By-Product (DBP) Precursors: Natural Organic Matter (NOM), such as humic and fulvic acids found in many surface waters, can react with disinfectants like chlorine to form harmful DBPs (e.g., trihalomethanes). NF membranes can effectively remove a significant portion of this NOM due to its relatively large molecular size, thus reducing DBP formation potential.

- Color Removal: Many surface waters have undesirable color due to dissolved organic compounds. NF is very effective at removing these color-causing molecules.

- Sulfate Removal: In some regions, groundwater can have high sulfate levels, which can cause taste issues and have laxative effects. NF can selectively remove sulfates.

- Nitrate Removal: Some specialized NF membranes show good rejection of nitrates, although RO is often preferred for very high nitrate concentrations.

2. Industrial Process Water

Many industries require water of specific quality for their processes.

- Boiler Feedwater Pre-treatment: While RO is often used for final demineralization of boiler feedwater, NF can be an effective pre-treatment step to remove hardness and some TDS, reducing scaling potential and the load on downstream RO or ion exchange units.

- Cooling Tower Make-up Water: NF can reduce hardness and silica in make-up water, minimizing scaling and blowdown frequency in cooling towers.

3. Wastewater Treatment and Resource Recovery

NF is increasingly used in wastewater treatment, not just for purification but also for recovering valuable resources.

- Heavy Metal Removal: As I mentioned earlier, NF has a high rejection rate for divalent heavy metal ions like copper (Cu²⁺), nickel (Ni²⁺), zinc (Zn²⁺), and lead (Pb²⁺). This is crucial for treating industrial effluents from plating industries, mining operations, and electronics manufacturing. One of my insights is that NF shows >95% rejection for divalent heavy metal ions (e.g., Cu²⁺, Ni²⁺) while allowing monovalent ions (e.g., Na⁺) to pass, making it more suitable than RO for pre-treating high-salinity wastewater containing these metals.

- Dye Removal and Recovery: The textile industry produces wastewater with high concentrations of dyes. NF can effectively remove these dyes, allowing for water reuse and, in some cases, recovery of the concentrated dye. I worked on a project for a denim manufacturer where NF helped them meet stringent discharge limits and significantly reduce their water consumption.

- COD/BOD Reduction: NF can remove a portion of the Chemical Oxygen Demand (COD) and Biochemical Oxygen Demand (BOD) by rejecting larger organic molecules present in some industrial and municipal wastewaters.

- Phosphate Recovery: In some wastewater streams, NF can be used to concentrate and recover phosphates, which can then be reused as fertilizer.

4. Food and Beverage Industry

The gentle separation capabilities of NF, operating at lower pressures than RO, make it very suitable for the food and beverage sector.

- Juice Concentration: NF can concentrate fruit juices by removing water while retaining sugars, acids, flavors, and colors.

- Dairy Industry:

- Whey Protein Concentration and Demineralization: NF is widely used to concentrate whey proteins and simultaneously remove some of the minerals (demineralization), particularly monovalent salts, to produce various whey protein products.

- Lactose Reduction/Removal: It can be used in processes to reduce lactose content in milk products.

- Sugar Refining: NF can be used for demineralization and color removal in sugar solutions.

- Extract Clarification and Concentration: For products like tea or coffee extracts, NF can play a role. My insight here is that nanofiltration can selectively retain target components based on molecular weight differences (e.g., tea polyphenols approx. 300-500 Da, caffeine approx. 194 Da) while removing small molecule impurities (like water, inorganic salts), avoiding the loss of low molecular weight active ingredients that can occur with RO membranes. This allows for a more refined product.

5. Pharmaceutical and Biotechnology Industries

The precision of NF is highly valued in these sensitive applications.

- API (Active Pharmaceutical Ingredient) Concentration and Purification: NF can concentrate APIs and separate them from impurities or solvents. My insight here is critical: Nanofiltration can retain active pharmaceutical ingredients (molecular weight approx. 300-1000 Da) while removing inorganic salts and small molecule impurities, avoiding the excessive retention of low molecular weight drugs by RO membranes. The lower operating pressure can reduce the risk of deactivating bioactive substances (like enzymes, antibodies), which is superior to the high-pressure environment of RO, giving it an irreplaceable role in the pharmaceutical industry. I’ve consulted on systems where this gentle, selective separation was key to maintaining product efficacy.

- Fractionation of Biomolecules: Separating proteins, enzymes, or other biomolecules based on size.

- Antibiotic Purification and Concentration.

- Solvent Recovery: Recovering valuable solvents used in pharmaceutical manufacturing processes.

6. Chemical Industry

- Catalyst Recovery: Separating and recovering valuable catalysts from reaction mixtures.

- Product Purification and Concentration: Various applications where selective separation of chemical species is needed.

Uses of Nanofiltration Membranes: A Quick Overview

| Industry/Application Sector | Specific Uses | Key Benefits |

|---|---|---|

| Drinking Water | Softening, DBP precursor removal, color removal, sulfate removal | Improved water quality, reduced chemical use, lower DBP formation |

| Industrial Process Water | Boiler feed pre-treatment, cooling tower make-up | Reduced scaling, improved efficiency, lower maintenance costs |

| Wastewater Treatment | Heavy metal removal, dye removal/recovery, COD/BOD reduction, phosphate recovery | Compliance with discharge limits, water reuse, resource recovery |

| Food & Beverage | Juice concentration, whey protein processing, lactose reduction, extract refining | Gentle processing, improved product quality, new product development |

| Pharmaceutical/Biotech | API concentration, biomolecule fractionation, antibiotic purification, solvent recovery | High purity, preservation of bioactivity, efficient separation |

| Chemical Industry | Catalyst recovery, product purification | Increased yield, reduced waste, cost savings |

The list goes on, and new applications are continually being developed as membrane technology advances. The beauty of NF lies in its ability to perform "molecular sieving" at a scale that bridges the gap between ultrafiltration and reverse osmosis, offering unique separation possibilities. As an engineer who loves finding the right solution for each unique water challenge, NF is definitely one of my go-to technologies.

When to use nanofiltration?

Deciding if NF is the right choice for your specific needs? Worried that choosing the wrong water treatment technology could waste precious resources? Let's pinpoint the ideal scenarios for using nanofiltration.

You should consider using nanofiltration when you need to selectively remove multivalent ions (like for water softening) or specific larger organic molecules. It's a good option when complete desalination, like that provided by RO, isn't necessary or would be too costly in terms of energy.

Choosing the right water treatment technology is like picking the right tool for a construction project. You wouldn't use a sledgehammer to tap in a small nail. Similarly, you wouldn't necessarily use full-blown reverse osmosis if nanofiltration can do the job more efficiently and economically. Over my years, I’ve helped many clients navigate this decision. Here’s when I typically find nanofiltration to be the star player:

1. When Selective Ion Removal is Key?

This is the hallmark of NF.

- Water Softening: If your main problem is hard water (high calcium and magnesium) but you don't need to remove all dissolved salts, NF is often perfect. It targets those divalent hardness ions while allowing most monovalent ions (like sodium and chloride) to pass. This means you get softer water without the very low TDS (Total Dissolved Solids) that RO produces, which can sometimes be too aggressive or require remineralization. I often recommend NF for municipal softening where maintaining some mineral content is desirable.

- Sulfate Reduction: If high sulfate levels are an issue, NF can selectively remove sulfate ions (SO₄²⁻) without significantly impacting other salts.

- Targeted Heavy Metal Removal from Mixed Salt Streams: When you need to remove divalent heavy metals (like Cu²⁺, Ni²⁺ from industrial wastewater) but the wastewater also contains high levels of monovalent salts (like NaCl). NF can remove the heavy metals while letting much of the NaCl pass, reducing the osmotic pressure and burden on any downstream treatment like RO. As per my insight, NF’s ability to reject >95% of divalent heavy metal ions while allowing monovalent ions through makes it more suitable than RO for pre-treating high-salinity wastewater.

2. For Removal of Larger Organic Molecules and Color

- Natural Organic Matter (NOM) and Disinfection By-Product (DBP) Precursor Removal: If your surface water source is high in NOM (humic and fulvic acids), NF can effectively remove these larger organic molecules. This not only improves the aesthetic quality of the water (reducing color and taste/odor issues) but also significantly lowers the potential for forming harmful DBPs when the water is disinfected.

- Color Removal: NF is excellent for removing color bodies from water, which are often complex organic molecules.

- Pesticide/Herbicide Removal: Many pesticides and herbicides are organic molecules large enough to be rejected by NF membranes.

3. As a Pre-treatment for Reverse Osmosis (RO)

This is a very common and smart application.

- Reducing Scaling and Fouling on RO Membranes: By removing hardness ions (Ca²⁺, Mg²⁺) and larger organic foulants, NF can protect downstream RO membranes. This reduces the frequency of RO cleaning, extends RO membrane life, and can allow the RO system to operate at a higher recovery rate. I’ve implemented NF pre-treatment in several projects where the feed water was challenging for RO alone, and it made a huge difference in the RO system's stability and operational costs. My insight applies here too: Compared to RO, NF is better suited for pre-treating high-salinity wastewater, especially if that salinity includes significant hardness.

- Lowering Operating Pressure for RO: By reducing the overall TDS and particularly scaling ions, NF pre-treatment can sometimes allow the downstream RO to operate at a slightly lower pressure.

4. In Specific Industrial Processes Requiring Molecular Separation

- Food and Beverage Industry: For concentrating juices, demineralizing whey, or fractionating components where you want to retain smaller flavor or nutritional molecules while removing water or specific salts. Recalling my insight: Nanofiltration can selectively retain target components based on molecular weight differences (e.g., tea polyphenols approx. 300-500 Da, caffeine approx. 194 Da), while removing small molecule impurities, avoiding the loss of low molecular weight active ingredients by RO membranes. This selective retention is crucial.

- Pharmaceutical and Biotechnology: For concentrating Active Pharmaceutical Ingredients (APIs), purifying antibiotics, or fractionating biomolecules where gentle processing and specific molecular weight cut-offs are needed. Again, an important insight: Nanofiltration can retain APIs (MW ~300-1000 Da) while removing salts and small impurities. The lower operating pressure reduces the risk of deactivating bioactive substances (like enzymes, antibodies), making it superior to RO's high-pressure environment in many pharmaceutical applications.

- Dye Recovery in Textile Industry: Separating and concentrating dyes from wastewater for reuse.

5. When Energy Costs are a Major Concern and Full Demineralization Isn't Needed

Since NF operates at significantly lower pressures than RO, the energy consumption is lower. If the treatment objective can be met by NF (e.g., partial demineralization, softening, organic removal), it will generally be more energy-efficient and thus have lower operating costs than an RO system designed for the same flow rate. This was a deciding factor for a remote community project I worked on, where energy resources were limited.

Decision Factors: A Quick Checklist

When considering NF, I always go through a mental checklist with my clients, often backed by detailed water analysis and pilot testing if the water is complex:

| Factor | Question to Ask | Why it Matters for NF |

|---|---|---|

| Feed Water Quality | What are the levels of hardness, TDS, organics, specific ions, turbidity, SDI? | Determines pre-treatment needs and if NF can achieve the desired separation. |

| Permeate Quality Target | What needs to be removed? What level of purity is required? What can remain? | NF is for selective removal, not total purification like RO. |

| Operating Costs (OPEX) | What is the cost of energy? What are the chemical and labor costs for cleaning? | NF is generally lower in energy than RO but has its own OPEX. |

| Capital Costs (CAPEX) | What is the budget for the system, including pre-treatment and installation? | NF systems can have different CAPEX than RO or other alternatives. |

| Fouling Potential | How prone is the water to causing scaling, organic, or biofouling? | High fouling potential necessitates robust pre-treatment for NF. |

| Concentrate Disposal | How will the NF reject stream be managed? Are there regulations or costs involved? | All membrane systems produce concentrate. |

| Space Availability | How much footprint is available for the treatment system? | NF systems, like other membrane plants, require a certain amount of space. |

When NOT to use NF (typically):

- When you need almost complete removal of all dissolved salts (e.g., for boiler feed for high-pressure boilers, ultrapure water for electronics, seawater desalination for drinking water in most cases). RO is usually the choice here.

- When the primary goal is to remove very small, uncharged molecules that can pass through NF membranes.

- When feed water has extremely high fouling potential that cannot be economically managed with pre-treatment.

Pilot testing is something I always recommend for non-standard applications or challenging water sources. It provides real-world data on how an NF membrane will perform with that specific water, helping to fine-tune the design and avoid costly surprises. It’s an investment that pays off. Speaking with data is key, and pilot tests give us that crucial data.

Conclusion

Nanofiltration is a versatile membrane technology. It offers unique, selective separation for many water treatment and industrial processes, effectively bridging ultrafiltration and RO.