Water treatment can be confusing with so many filtration technologies available. When choosing between ultrafiltration (UF) and reverse osmosis (RO) membranes, understanding their differences is crucial for selecting the right solution for your needs.

UF membranes remove particles, bacteria, and some viruses using physical filtration with pore sizes of 0.01-0.1 microns, while RO membranes have much smaller pores (0.0001 microns) that can remove dissolved salts and contaminants through a semi-permeable membrane using pressure.

In my twelve years of experience in water treatment, I've helped countless clients choose between these two important membrane technologies. The choice between UF and RO depends on your specific water quality goals, budget constraints, and maintenance capabilities. Let's explore the key differences to help you make an informed decision.

What is the use of UF membrane?

Many water treatment systems fail because people choose the wrong filtration technology. UF membranes offer an effective balance between filtration performance and operational costs for many applications where dissolved solids removal isn't required.

Ultrafiltration membranes are primarily used to remove suspended solids, bacteria, viruses, and high molecular weight contaminants from water. They're effective for clarification, disinfection, and pre-treatment in municipal water systems, food and beverage processing, and as pre-treatment for RO systems.

How UF Membranes Work?

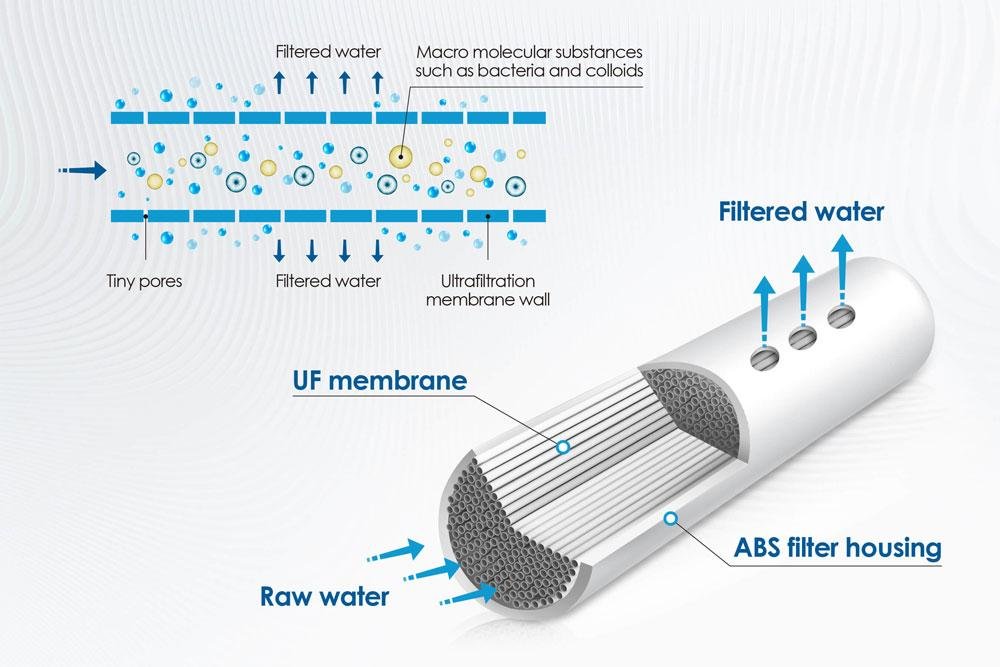

UF membranes operate using a simple physical filtration mechanism with pore sizes ranging from 0.01 to 0.1 microns. These pores are large enough to allow water and dissolved minerals to pass through while blocking larger contaminants. The process requires relatively low pressure (typically 1-3 bar), making it energy-efficient compared to other membrane technologies.

When water enters the UF system, it passes through hollow fiber membranes that trap contaminants on the outside while allowing clean water to flow through to the inside. This design creates a physical barrier that effectively removes:

- Bacteria (>99.99% removal)

- Protozoa and cysts

- Most viruses

- Suspended solids

- Colloids

- Some large organic molecules

In my experience working with a dairy processing plant, we installed UF membranes to remove bacteria and suspended solids from their process water. The system operated at just 2 bar pressure while providing consistently clean water that met their production requirements, saving them significant energy costs compared to other options.

Applications of UF Membranes

| Application | Benefits of UF | Typical Results |

|---|---|---|

| Drinking Water Treatment | Removes pathogens, maintains minerals | SDI<3, >4-log bacteria removal |

| Industrial Pre-treatment | Protects downstream systems, reduces fouling | Turbidity <0.1 NTU |

| Wastewater Reclamation | Cost-effective filtration, high recovery rates | 85-95% water recovery |

| Food & Beverage | Non-thermal separation, preserves nutrients | Protein concentration, clarification |

| Pharmaceutical | Pyrogen removal, protein separation | Endotoxin removal, fractionation |

What is the lifespan of ultrafiltration membrane?

The recurring replacement costs of filtration membranes often surprise system owners. Understanding the typical lifespan of UF membranes helps plan for maintenance and calculate the true cost of ownership.

Ultrafiltration membranes typically last 3-5 years in municipal applications and 2-4 years in industrial settings, though this varies based on water quality, operating conditions, cleaning frequency, and membrane material quality. With proper maintenance, some UF systems can reach 7+ years of service.

Factors Affecting UF Membrane Lifespan

The lifespan of ultrafiltration membranes depends on multiple interconnected factors that system operators should understand to maximize their investment. Having installed and maintained hundreds of UF systems, I've observed these critical factors:

-

Feed Water Quality: This is perhaps the most significant factor. Higher turbidity, organic loading, and chemical contaminants accelerate membrane fouling and degradation. I once worked with a beverage manufacturer whose UF membranes were failing after just 8 months. After analyzing their feed water, we discovered seasonal agricultural runoff was introducing organic compounds that fouled the membranes. Installing proper pre-filtration extended their membrane life to over 3 years.

-

Operating Parameters: Pressure excursions, improper flux rates, and inadequate backwashing schedules can irreversibly damage membranes. Systems that operate consistently within design specifications typically see longer membrane life.

-

Cleaning Regimen: The frequency and effectiveness of chemical cleanings significantly impact membrane longevity. Too infrequent cleaning allows fouling to become permanent, while overly aggressive chemical cleaning can damage the membrane material.

-

Membrane Material: PVDF (polyvinylidene fluoride) membranes generally offer better chemical and temperature resistance than PES (polyethersulfone) or PS (polysulfone) membranes, potentially extending service life in challenging applications.

-

System Design: Proper system design with adequate pre-treatment, optimized flow distribution, and appropriate automation controls helps prevent conditions that damage membranes.

In a municipal water treatment plant I consulted for, we implemented an automated monitoring system that triggered cleanings based on transmembrane pressure differentials rather than fixed time intervals. This approach reduced chemical usage by 30% while extending membrane life from 3.5 to 5.2 years, demonstrating how intelligent operation can significantly impact membrane lifespan and operational costs.

How do you clean ultrafiltration membranes?

Many UF systems underperform because of inadequate cleaning procedures. Proper cleaning protocols can restore membrane performance and extend service life significantly.

Ultrafiltration membranes are cleaned through a combination of hydraulic backwashing (reversing water flow) and chemical cleaning (CIP). Regular backwashing (every 15-60 minutes) removes surface deposits, while chemical cleaning (weekly to monthly) using acids, bases, and surfactants removes stubborn organic and inorganic fouling.

Ultrafiltration Membrane Cleaning Methods in Detail

Effective cleaning of UF membranes requires a strategic approach that addresses different types of fouling. Throughout my career, I've developed and refined cleaning protocols for various applications, and I've found that a well-designed cleaning regimen typically involves multiple stages:

Hydraulic Cleaning Methods

-

Backwashing: This is the primary cleaning mechanism for UF systems, performed automatically every 15-60 minutes depending on feed water quality. During backwashing, filtrate water flows in reverse through the membrane to dislodge particles from the membrane surface. For hollow fiber configurations, this expands the fibers and releases trapped solids.

-

Air Scouring: Many modern UF systems combine backwashing with air scouring, where compressed air is introduced to create turbulence and enhance the cleaning effect. This creates a more effective cleaning action than water alone, particularly for removing cake-like deposits.

-

Forward Flush: High-velocity forward flushing helps remove accumulated solids from the feed channels without reversing flow. This is particularly useful in spiral-wound configurations where backwashing may not be possible.

Chemical Cleaning Processes

Chemical cleaning becomes necessary when hydraulic cleaning no longer effectively restores membrane performance. Generally, chemical cleaning is categorized into:

-

Maintenance Cleaning (MC): Performed more frequently (weekly or bi-weekly) with lower chemical concentrations for shorter durations (30-60 minutes).

-

Clean-In-Place (CIP): More intensive cleaning performed less frequently (monthly or quarterly) with higher chemical concentrations for extended periods (4-8 hours).

The chemical agents selected depend on the fouling type:

| Fouling Type | Chemical Agents | Typical Concentration | Contact Time |

|---|---|---|---|

| Organic Fouling | Sodium Hypochlorite (NaOCl), Caustic (NaOH) | 200-500 ppm (NaOCl), 0.01-0.1% (NaOH) | 1-4 hours |

| Inorganic Scaling | Citric Acid, Hydrochloric Acid | 0.2-2% | 1-4 hours |

| Biofouling | Sodium Bisulfite, Specialized Biocides | 0.1-1% | 1-6 hours |

| Mixed Fouling | Sequential Acid/Base Cleaning | Varies | Multiple cycles |

I recently helped troubleshoot a pharmaceutical water system where membrane performance had declined by 40%. Standard cleaning protocols weren't restoring flux. Through water analysis and membrane autopsy, we identified a complex fouling layer containing both calcium phosphate scaling and biofilm. We developed a custom two-stage cleaning protocol: first using a proprietary enzyme cleaner to break down the biofilm, followed by a chelating acid cleaner to dissolve the mineral scale. This restored 95% of the original performance without membrane replacement, saving the client over $30,000 in capital costs.

Key Differences Between UF and RO Membranes

Having discussed UF membranes in detail, let's directly compare them to RO membranes to highlight the fundamental differences:

| Feature | UF Membrane | RO Membrane |

|---|---|---|

| Pore Size | 0.01-0.1 microns | 0.0001 microns (100x smaller) |

| Removal Capability | Bacteria, viruses, colloids, particles | All UF removals plus dissolved salts, most organics |

| Operating Pressure | 1-3 bar | 10-60 bar |

| Energy Consumption | Low | High (3-10x that of UF) |

| Water Recovery | 90-95% | 50-85% |

| Dissolved Solids Removal | Minimal | Excellent (95-99%) |

| Maintenance Frequency | Moderate | High |

| Initial Investment | Lower | Higher |

| Applications | Pre-treatment, particle removal | Desalination, high-purity water |

| Membrane Configuration | Typically hollow fiber | Typically spiral-wound |

This comparison highlights why system selection must be based on specific water treatment objectives. For applications requiring removal of suspended solids and microbiological contamination while retaining beneficial minerals, UF is often the more economical choice. For applications requiring removal of dissolved salts or creation of high-purity water, RO is necessary despite its higher energy consumption and waste production.

In my work designing water systems for various industries, I've found that the best solution often involves combining these technologies. For example, in a recent food processing plant project, we installed UF as pretreatment to an RO system. The UF removed particles and microorganisms that would foul the RO membranes, while the RO provided the final demineralization needed for their process. This combination maximized the RO membrane life while achieving the required water quality specifications.

Conclusion

UF and RO membranes serve different water treatment needs based on their filtration capabilities and operating requirements. Understanding these differences helps you select the right technology for your specific water quality goals and operational constraints.