I spent years working with manufacturing facilities, and one truth became clear: choosing the wrong sewage treatment system costs you more than money. It costs you time, compliance headaches, and sometimes your reputation. The decision feels overwhelming because it is.

Selecting integrated sewage treatment equipment requires matching your specific waste characteristics, flow volume, and discharge standards with the right technology and capacity. The right system treats your wastewater effectively while staying within budget and meeting local regulations without constant maintenance issues.

When I first encountered this challenge at a client's facility, I made mistakes that taught me valuable lessons. The equipment looked perfect on paper, but we missed critical details about our actual needs. I will walk you through everything I learned, so you avoid the same costly errors.

What Are the Main Types of Integrated Sewage Treatment Systems Available?

I have seen facilities rush into purchasing decisions without understanding their options. Each system type serves different purposes, and knowing the differences saves you from regret later. The technology you choose determines your operational costs for years.

Integrated sewage treatment systems include activated sludge systems, membrane bioreactors (MBR), sequencing batch reactors (SBR), moving bed biofilm reactors (MBBR), and packaged treatment plants. Each technology offers distinct advantages for specific wastewater characteristics and treatment goals.

Understanding Each System Technology in Detail

The activated sludge system remains the most common choice. I worked with one in my early days, and it taught me about biological treatment fundamentals. Microorganisms consume organic pollutants in an aeration tank, then settle in a clarifier. The system works reliably but requires space and skilled operators.

MBR systems combine biological treatment with membrane filtration. I recommended this technology to a pharmaceutical client who needed superior effluent quality. The membranes replace traditional clarifiers, producing cleaner water in a smaller footprint. However, membrane replacement costs add up over time.

SBR systems operate in batches rather than continuously. One manufacturer I worked with loved their SBR because it handled varying flow rates well. The same tank performs all treatment steps in sequence: fill, react, settle, decant, and idle. This flexibility suits facilities with inconsistent wastewater production.

MBBR technology uses plastic carriers that host biofilm growth. I saw this system excel at a food processing plant where shock loads were common. The carriers move freely in the tank, providing high surface area for bacteria while resisting process upsets better than activated sludge alone.

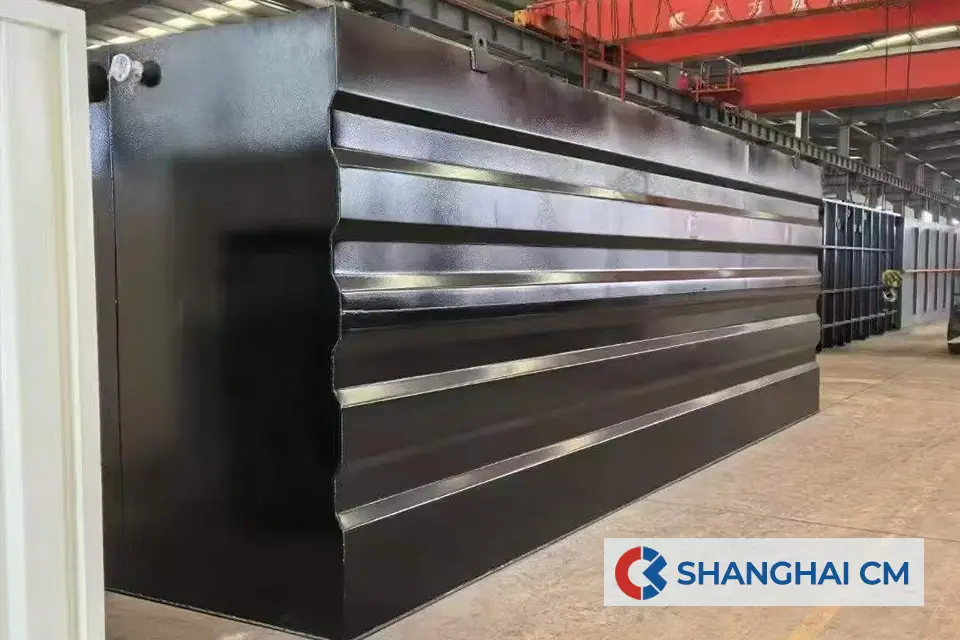

Packaged treatment plants integrate multiple processes into pre-engineered units. Small facilities appreciate these turnkey solutions. I helped a remote industrial site install one, and they valued the simplified procurement and faster installation compared to custom-designed systems.

| System Type | Space Requirements | Effluent Quality | Operating Complexity | Capital Cost | Operating Cost |

|---|---|---|---|---|---|

| Activated Sludge | High | Good | Medium | Medium | Medium |

| MBR | Low | Excellent | Medium-High | High | High |

| SBR | Medium | Good | Medium | Medium | Medium |

| MBBR | Medium | Good-Excellent | Low-Medium | Medium-High | Medium |

| Packaged Plant | Low | Good | Low | Medium-High | Medium |

How Do You Determine the Right Treatment Capacity for Your Facility?

I remember one client who undersized their system by 30%. Within six months, they faced daily overflows and regulatory notices. Capacity planning seems straightforward but requires careful analysis of current and future needs.

Calculate treatment capacity by measuring your peak daily flow, accounting for future growth, adding safety factors for unexpected increases, and considering seasonal variations. Your system must handle maximum loads without compromising treatment quality or causing equipment failures.

Breaking Down Capacity Calculation Steps

Start by measuring your actual wastewater generation. I always recommend installing flow meters for at least two weeks to capture daily variations. Do not rely on theoretical calculations alone. Real data reveals patterns you might miss otherwise.

Peak flow matters more than average flow. I learned this lesson when a system designed for average flow failed during production peaks. Your equipment must handle the highest flow you will ever produce. Industry standards typically recommend designing for 1.5 to 2 times your current average flow.

Future growth planning prevents premature obsolescence. I worked with a growing manufacturer who planned for 50% expansion within five years. We sized their system accordingly, and when they did expand, their treatment capacity kept pace. This foresight saved them from a second major capital investment.

Seasonal variations affect many industries. A beverage manufacturer I advised had summer flows 40% higher than winter. We designed their system for peak season demands. Understanding your annual cycle ensures year-round compliance without oversizing dramatically.

The type of wastewater influences capacity requirements. High-strength industrial wastewater requires longer retention times than domestic sewage. I calculate hydraulic retention time and organic loading rates to ensure adequate treatment. These parameters directly affect the size of your treatment tanks.

What Key Specifications Should You Evaluate When Comparing Systems?

I have reviewed countless equipment specifications, and most buyers focus on the wrong details. Price catches attention first, but specifications determine whether a system actually works for your application. I learned to create evaluation matrices that compare what truly matters.

Critical specifications include treatment efficiency percentages, BOD and COD removal rates, suspended solids removal, nutrient removal capabilities, footprint dimensions, power consumption, automation level, and maintenance requirements. These factors directly impact your operational success and costs.

Analyzing Specifications That Impact Performance

Treatment efficiency percentages tell you what the system can achieve. I always verify these claims by requesting reference installations with similar wastewater. A system rated for 95% BOD removal sounds impressive, but does it achieve that with your specific waste characteristics? Ask for performance data from comparable applications.

BOD and COD removal rates indicate organic pollutant treatment effectiveness. I worked with a textile facility where COD levels were extremely high. We needed a system proven to handle their specific organic load. Your discharge limits determine what removal rates you require.

Suspended solids removal affects effluent clarity and downstream equipment. I have seen poor solids removal clog irrigation systems and harm receiving waters. MBR systems excel here, but simpler technologies can also achieve good results with proper design.

Nutrient removal capabilities matter increasingly as regulations tighten. I helped a facility in a sensitive watershed select technology with nitrogen and phosphorus removal. Not all systems remove nutrients effectively. Verify this capability if your discharge limits include nutrient restrictions.

Footprint dimensions determine whether a system physically fits your site. I once specified perfect equipment that could not fit through the installation access point. Measure your available space carefully, including clearances for maintenance access and future component replacement.

Power consumption directly affects operating costs. I calculate annual energy costs for each system option. A more efficient system might cost more initially but save money over its lifetime. Some technologies consume significantly more power than others for equivalent treatment.

Automation level influences staffing requirements and operational reliability. I prefer systems with good process monitoring and automated controls. These features reduce operator workload and catch problems before they become emergencies. However, more automation means more complex troubleshooting.

Maintenance requirements include routine tasks, spare parts costs, and specialized service needs. I learned to request detailed maintenance schedules from vendors. Some systems need daily attention while others run for weeks with minimal intervention. Factor these differences into your total cost of ownership.

How Do Local Regulations and Discharge Standards Affect Your Equipment Choice?

I watched a company purchase equipment before checking their discharge permit. The system could not meet phosphorus limits, and they spent additional money on chemical treatment. Regulations should drive your equipment selection, not follow it.

Local discharge standards establish minimum treatment requirements that your equipment must achieve consistently. These limits vary by location, receiving water body sensitivity, and intended water reuse. Your system must reliably meet the most stringent applicable standard with margin for variation.

Navigating Regulatory Requirements Effectively

Start by obtaining your current discharge permit or application requirements. I review these documents carefully with clients. The permit specifies exact limits for parameters like BOD, suspended solids, pH, nutrients, and sometimes specific chemicals. Your equipment must address every listed parameter.

Future regulatory trends matter too. I have seen standards tighten significantly over a system's lifetime. Regulations generally become stricter, not looser. I recommend selecting technology with capacity to meet foreseeable future requirements without major modifications.

Some locations require specific treatment technologies. I encountered this in environmentally sensitive areas where authorities mandated certain processes. Research any technology-based standards that apply in your jurisdiction before finalizing equipment choices.

Monitoring and reporting requirements affect operational costs. Some permits require continuous monitoring with automated reporting. Others accept periodic grab samples. Your system should facilitate whatever monitoring your permit demands. I have specified equipment with integrated sampling ports and monitoring capabilities.

Backup and redundancy requirements exist in some jurisdictions. Critical facilities might need duplicate treatment capacity to prevent discharge violations during maintenance or equipment failures. I designed systems with parallel treatment trains for clients with strict reliability requirements.

Pretreatment standards apply if you discharge to a municipal system. I worked with industrial clients who needed specific pretreatment before sending wastewater to the city. These standards can be as strict as direct discharge limits. Verify requirements with your receiving authority.

What Are the Total Cost Considerations Beyond the Initial Purchase Price?

I have seen buyers celebrate low purchase prices only to regret their decision when operating costs became clear. The purchase price represents only the beginning. I always calculate total cost of ownership over the equipment's expected life to compare options fairly.

Total costs include initial equipment price, installation and construction, commissioning and startup, energy consumption, chemical additives, maintenance and repairs, operator labor, sludge disposal, monitoring and testing, and eventual replacement or upgrades. These factors often exceed the initial purchase price over time.

Calculating Long-Term Ownership Costs Accurately

Installation and construction costs vary widely. I worked on a project where site preparation and installation cost more than the equipment itself. Consider foundations, piping, electrical work, controls installation, and building modifications. Get detailed installation estimates early.

Commissioning and startup involve vendor support, testing, and adjustments. I budget for several weeks of vendor presence during startup. This period ensures proper operation before your team takes over. Rushing commissioning leads to ongoing problems.

Energy consumption creates a monthly expense that continues for decades. I calculate annual energy costs based on power requirements and local utility rates. Energy-efficient systems often justify higher initial prices through operational savings.

Chemical additives include pH adjustment, nutrient supplementation, and disinfection chemicals. I helped a facility budget chemical costs that exceeded their expectations. Some treatment processes require significant chemical inputs while others minimize chemical use.

Maintenance and repairs include routine service, replacement parts, and unexpected breakdowns. I request maintenance schedules and typical parts costs from vendors. Budget for regular maintenance and create a reserve for unexpected repairs.

Operator labor depends on system complexity and automation. I calculate annual labor costs based on required operator skill level and time commitment. Highly automated systems might require less routine attention but need more skilled troubleshooting when problems arise.

Sludge disposal represents a significant ongoing expense. I worked with facilities spending thousands monthly on sludge hauling and disposal. Treatment processes vary in sludge production. Less sludge means lower disposal costs.

Monitoring and testing ensure compliance and proper operation. I include laboratory fees, testing equipment, and supplies in operating budgets. Some treatment processes require more frequent monitoring than others.

Eventually, major components need replacement or systems require upgrades. I plan for membrane replacement in MBR systems, blower rebuilds, and control system updates. These periodic expenses should factor into long-term financial planning.

How Important Is Vendor Support and Service Availability?

I learned about vendor support importance the hard way. A client purchased equipment from a distant supplier who could not provide timely service. When problems occurred, response took days, and compliance suffered. Vendor support becomes critically important when your system struggles.

Vendor support quality determines how quickly you resolve problems, access replacement parts, receive training, and implement improvements. Choose suppliers with local service presence, responsive technical support, comprehensive parts inventory, and proven long-term commitment to their equipment lines.

Evaluating Vendor Capabilities Before Purchase

Start by researching vendor reputation. I contact existing customers for honest feedback about their support experiences. Ask about response times, technical competence, and willingness to address problems. A vendor's track record predicts your future experience.

Local service presence matters tremendously. I prioritize vendors with nearby service centers or representatives. When equipment fails, hours matter. Remote support has limitations. Local technicians can arrive quickly with parts and tools.

Technical support availability should extend beyond normal business hours. Treatment systems do not fail conveniently during weekday daytime. I verify whether vendors offer 24/7 emergency support. How quickly can you reach someone who can actually help?

Parts availability affects downtime duration. I ask vendors about their parts inventory and typical delivery times for critical components. Some suppliers stock common parts locally while others ship from overseas. Lengthy parts delays can cause extended outages.

Training programs help your team operate and maintain equipment effectively. I always request comprehensive training during commissioning. Good vendors provide detailed manuals, online resources, and ongoing training opportunities as technology evolves.

Warranty terms reveal vendor confidence in their equipment. I carefully review warranty coverage, duration, and exclusions. Understand what the warranty covers and what remains your responsibility. Extended warranties might make sense for critical systems.

Long-term commitment to product lines matters. I avoid vendors with frequently changing product offerings. Established systems with long production histories ensure parts availability and continued support years later.

What Are Common Mistakes to Avoid When Selecting Treatment Equipment?

I have witnessed and made many selection mistakes over my years in this field. These errors cost money, time, and frustration. Learning from these mistakes helps you make better decisions.

Common mistakes include undersizing for future growth, ignoring actual wastewater characteristics, selecting incompatible technology, focusing only on initial cost, neglecting operator skill requirements, overlooking space constraints, and failing to verify vendor claims. Each mistake creates problems you will eventually face.

Understanding Each Mistake and How to Prevent It

Undersizing for future growth forces premature replacement or expensive expansions. I always recommend planning for at least five years of growth. The incremental cost of additional capacity during initial construction is much less than later expansion.

Ignoring actual wastewater characteristics leads to poor performance. I insist on comprehensive wastewater analysis before selecting technology. Treatment requirements vary dramatically based on contaminant types and concentrations. Generic solutions rarely work optimally for specific applications.

Selecting incompatible technology happens when buyers do not match process capabilities to wastewater properties. I worked with a facility that purchased biological treatment for wastewater containing biocides. The system never performed properly because the chemicals killed the treatment microorganisms.

Focusing only on initial cost ignores total ownership expenses. I create lifecycle cost comparisons that reveal true financial impacts. A cheaper system with high operating costs often costs more over time than a more expensive but efficient alternative.

Neglecting operator skill requirements sets up operational failures. I assess available operator capabilities before recommending technology. Sophisticated systems need skilled operators. If you lack qualified staff, choose simpler technology or plan for extensive training.

Overlooking space constraints creates installation nightmares. I always verify physical dimensions and access requirements before specifying equipment. Consider not just the equipment footprint but also clearances for maintenance, future modifications, and component replacement.

Failing to verify vendor claims leads to disappointment. I request reference sites, performance data, and independent testing results. Visit operating installations if possible. See the equipment working under conditions similar to yours before committing.

How Do You Prepare Your Site and Infrastructure for System Installation?

I learned that proper preparation prevents installation delays and problems. Site readiness directly affects installation costs and timeline. I have seen projects delayed for months because basic site preparation was not completed before equipment arrival.

Site preparation includes foundation construction, utility connections, access improvements, environmental controls, safety measures, and operator facilities. Complete these tasks before equipment delivery to ensure smooth installation and timely startup.

Planning Site Preparation in Proper Sequence

Foundation construction must match equipment specifications exactly. I review foundation drawings carefully with structural engineers. Treatment equipment is heavy and generates vibration. Foundations must support loads and prevent settling that could damage equipment or piping.

Utility connections include electrical power, water supply, and drainage. I coordinate with utility providers early because service upgrades often involve long lead times. Verify that available power meets equipment requirements. Inadequate power causes operational problems.

Access improvements ensure equipment and materials reach installation locations. I walked sites where narrow gates prevented equipment delivery. Large treatment units sometimes arrive on oversized trucks. Verify that access routes can accommodate delivery vehicles and equipment dimensions.

Environmental controls protect sensitive areas during construction. I implement erosion control, stormwater management, and dust suppression measures. These precautions prevent environmental violations and maintain good relationships with neighbors and regulators.

Safety measures protect workers during installation. I work with contractors to establish safety protocols, protective barriers, and emergency procedures. Treatment system installation involves confined spaces, heavy equipment, and electrical hazards.

Operator facilities include control rooms, laboratories, and maintenance workshops. I plan these spaces to support daily operations effectively. Operators need comfortable, well-equipped areas to monitor systems, conduct tests, and perform maintenance.

What Questions Should You Ask Potential Equipment Vendors?

I developed a standard list of questions after learning what information truly matters. Asking the right questions reveals vendor capabilities and potential problems before you commit to a purchase.

Essential questions cover performance guarantees, reference installations, service capabilities, spare parts availability, training programs, warranty terms, upgrade options, and compliance support. Vendor responses help you evaluate their suitability for your specific needs.

Critical Questions That Reveal Important Information

Ask about performance guarantees with consequences for non-compliance. I want vendors to guarantee specific treatment levels with penalties if equipment fails to perform. This commitment demonstrates confidence and provides recourse if problems occur.

Request multiple reference installations with similar applications. I contact these references directly to ask about their experiences. Specific questions about challenges, vendor responsiveness, and long-term satisfaction reveal valuable insights.

Verify service capabilities including response times and technician qualifications. I ask about average response times for emergency service calls. Where are the nearest service technicians located? What qualifications and training do they possess?

Inquire about spare parts inventory and delivery times. I want to know what parts vendors stock locally and what typical lead times look like for critical components. Long parts delays extend downtime and threaten compliance.

Ask detailed questions about training programs. I request training schedules, materials provided, and whether training occurs at your site or requires travel. Comprehensive training ensures your team can operate equipment effectively.

Review warranty terms carefully and ask about exclusions. I want to understand exactly what the warranty covers, how long coverage lasts, and what actions might void warranty protection. Extended warranty options might provide valuable additional protection.

Discuss upgrade and expansion options. I ask whether systems can accommodate future capacity increases or technology improvements. Modular designs offer flexibility as needs change over time.

Request information about compliance support services. I value vendors who help with permitting, reporting, and regulatory interactions. This support proves especially valuable during startup and when regulations change.

Conclusion

Selecting integrated sewage treatment equipment demands careful evaluation of your specific needs against available technologies, costs, and vendor capabilities. The right choice delivers reliable compliance and manageable operating expenses for years. I hope my experiences help you avoid common mistakes and make a confident decision.