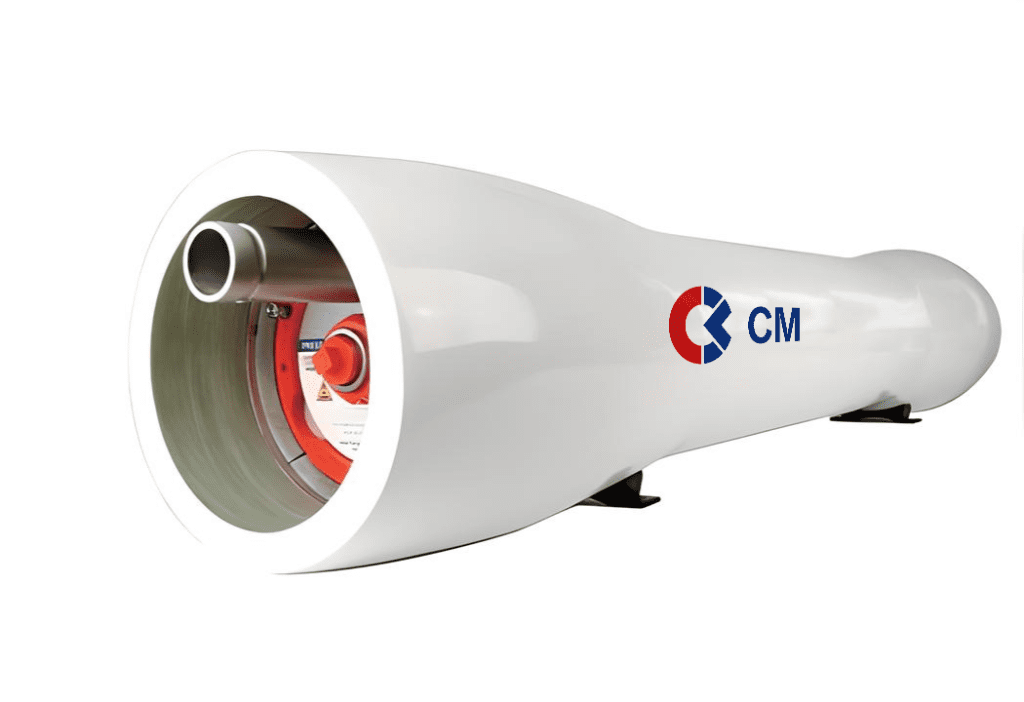

Product Overview

The fiberglass reverse osmosis membrane housing is a key component used in water treatment systems, offering numerous advantages. Firstly, fiberglass membrane housing is known for its high strength and durability, allowing it to withstand high-pressure environments and effectively resist external physical impacts, thereby reducing replacement or maintenance costs due to accidental damage. Additionally, fiberglass material has high chemical stability and strong resistance to chemical substances and common components in water, offering excellent anti-corrosion properties, which are especially beneficial for seawater and industrial wastewater treatment.

Compared to traditional metal housings, fiberglass membrane housing is lighter in weight, making it easier to install and transport, thereby reducing labor costs and structural load, and is suitable for various complex installation environments. It also offers design flexibility, as it can be customized according to system requirements, with a variety of sizes and interface types available. Moreover, fiberglass membrane housing has excellent insulation properties, enhancing the safety and heat resistance of system operation.

Its economic advantages are also significant, as the low maintenance frequency and costs, combined with a long service life due to its durability and corrosion resistance, make it a cost-effective choice. In summary, due to its outstanding performance in reliability and economic efficiency, fiberglass reverse osmosis membrane housing is an ideal choice in the water treatment industry, widely used in various scenarios such as seawater desalination, municipal water supply, and industrial wastewater treatment.

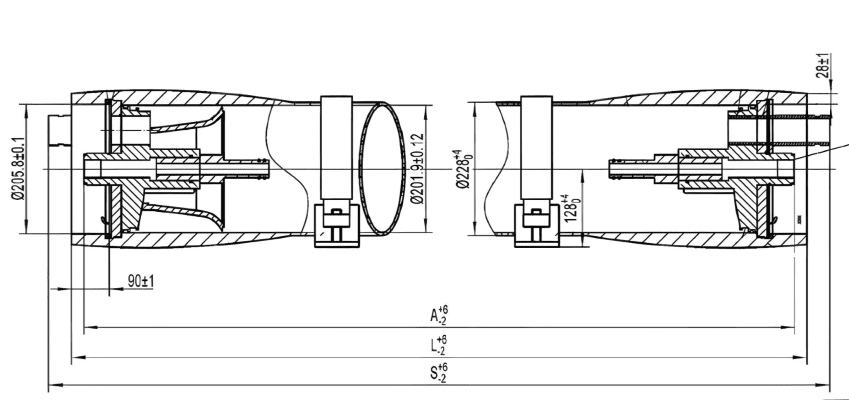

Product Dimensions

| Membrane Quantity | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| 300PSI | 232x232x1531 | 232x232x2547 | 232x232x3563 | 232x232x4579 |

| 450PSI | 235x235x1543 | 235x235x2559 | 235x235x3575 | 235x235x4591 |

| 600PSI | 250x250x1577 | 250x250x2593 | 250x250x3609 | 250x250x4625 |

| 1000PSI | 265x265x1623 | 265x265x2639 | 265x265x3655 | 265x265x4671 |

| 1200PSI | 270x270x1629 | 270x270x2645 | 270x270x3661 | 270x270x4677 |

| Membrane Quantity | 5 | 6 | 7 | 8 |

|---|---|---|---|---|

| 300PSI | 232x232x5595 | 232x232x6611 | 232x232x7627 | 232x232x8643 |

| 450PSI | 235x235x5607 | 235x235x6623 | 235x235x7639 | 235x235x8655 |

| 600PSI | 250x250x5641 | 250x250x6657 | 250x250x7673 | 250x250x8689 |

| 1000PSI | 265x265x5687 | 265x265x6703 | 265x265x7719 | 265x265x8735 |

| 1200PSI | 270x270x5693 | 270x270x6709 | 270x270x7725 | 270x270x8741 |

Unit: mm (D1×D2×L)

Product Parameters

8" End Port / Low Pressure

8" End Port / High Pressure

Technical Specifications

| Specification | 8" End Port / Low Pressure | 8" End Port / High Pressure |

|---|---|---|

| Model | W80E300/450 | W80E600/1000/1200 |

| Design Pressure | 300/450 Psi | 600/1000/1200 Psi |

| Cyclic Test | 100,000 times | 100,000 times |

| Burst Pressure | 6 | 6 |

| Elements Quantity | 1-8 | 1-8 |

| Operating pH Range | pH 3-11 | pH 3-11 |

| Operating Temperature | -10℃-66℃ (14℉-150℉) | -10℃-66℃ (14℉-150℉) |

| Feed / Concentration Port | 1.5" | 1.5" |

| Permeate Port | 1" | 1" |

Frequently Asked Questions

What is FRP, and why is it used for reverse osmosis membrane housings?

FRP stands for Fiberglass Reinforced Plastic, a composite material known for its high strength, corrosion resistance, and lightweight properties. These characteristics make FRP ideal for reverse osmosis (RO) membrane housings, as it can withstand high pressure and harsh environmental conditions while ensuring durability and long service life.

What are the benefits of using FRP membrane housings over other materials?

FRP membrane housings offer several advantages over other materials, such as stainless steel or PVC, including:

-

Corrosion Resistance: FRP is highly resistant to chemical corrosion, making it suitable for a wide range of water treatment applications.

-

Lightweight: FRP is lighter than metal, which reduces transportation and installation costs.

-

High Strength-to-Weight Ratio: Despite its lightweight nature, FRP provides excellent structural integrity and pressure tolerance.

-

Low Maintenance: FRP requires minimal maintenance compared to metals, as it does not rust or degrade easily.

How do I select the appropriate FRP membrane housing for my RO system?

Selecting the right FRP membrane housing depends on several factors, including:

-

Pressure Rating: Ensure the housing can handle the maximum operating pressure of your system.

-

Size and Configuration: Choose a housing that fits the number and size of membranes your system requires.

-

Chemical Compatibility: Ensure the housing material is compatible with the chemicals used in your specific water treatment process.

-

Temperature Range: Verify that the housing can withstand the operating temperature conditions of your system.

What maintenance is required for FRP membrane housings?

FRP membrane housings require minimal maintenance, but regular inspections are recommended to ensure optimal performance. Key maintenance tasks include:

-

Inspecting for Physical Damage: Check for cracks, scratches, or any signs of damage to the housing.

-

Monitoring Seals and O-rings: Ensure that seals and O-rings are in good condition to prevent leaks.

-

Cleaning: Clean the housing exterior to remove dirt and debris that may accumulate over time.

Can FRP membrane housings be used in high-temperature applications?

FRP membrane housings are generally suitable for use in moderate temperature applications. However, their temperature tolerance depends on the specific resin and reinforcement materials used in the FRP. It is essential to check the manufacturer's specifications for the maximum allowable temperature for your particular FRP housing model.

Are FRP membrane housings environmentally friendly?

FRP membrane housings are considered environmentally friendly due to their long lifespan and low maintenance requirements, which reduce waste and resource consumption. Additionally, advancements in FRP manufacturing technology have led to more sustainable production methods, further minimizing the environmental impact.

Do you offer installation and maintenance services?

We can provide detailed technical guidance and send technical engineers to the site to guide installation and commissioning when necessary.