Industrial Reverse Osmosis Systems

Reliable RO Solutions Designed for Real Industrial Water Conditions. High-capacity, engineered reverse osmosis systems for industrial and process water treatment projects.

What Are Industrial Reverse Osmosis Systems?

Industrial reverse osmosis (RO) systems are high-capacity water treatment solutions designed to remove dissolved salts, organics, and contaminants from industrial feed water sources. Unlike residential or light commercial RO units, industrial RO systems are engineered for continuous operation, complex and fluctuating water quality, and large-scale production demands.

Industrial RO systems are commonly used in process water production, boiler feed water treatment, and industrial wastewater reuse projects where stable permeate quality and long-term reliability are critical.

High-Capacity Processing

Engineered for continuous operation and large-scale production demands

Superior Contaminant Removal

Removes dissolved salts, organics, and industrial contaminants

Custom Engineering

Designed based on detailed analysis and project-specific conditions

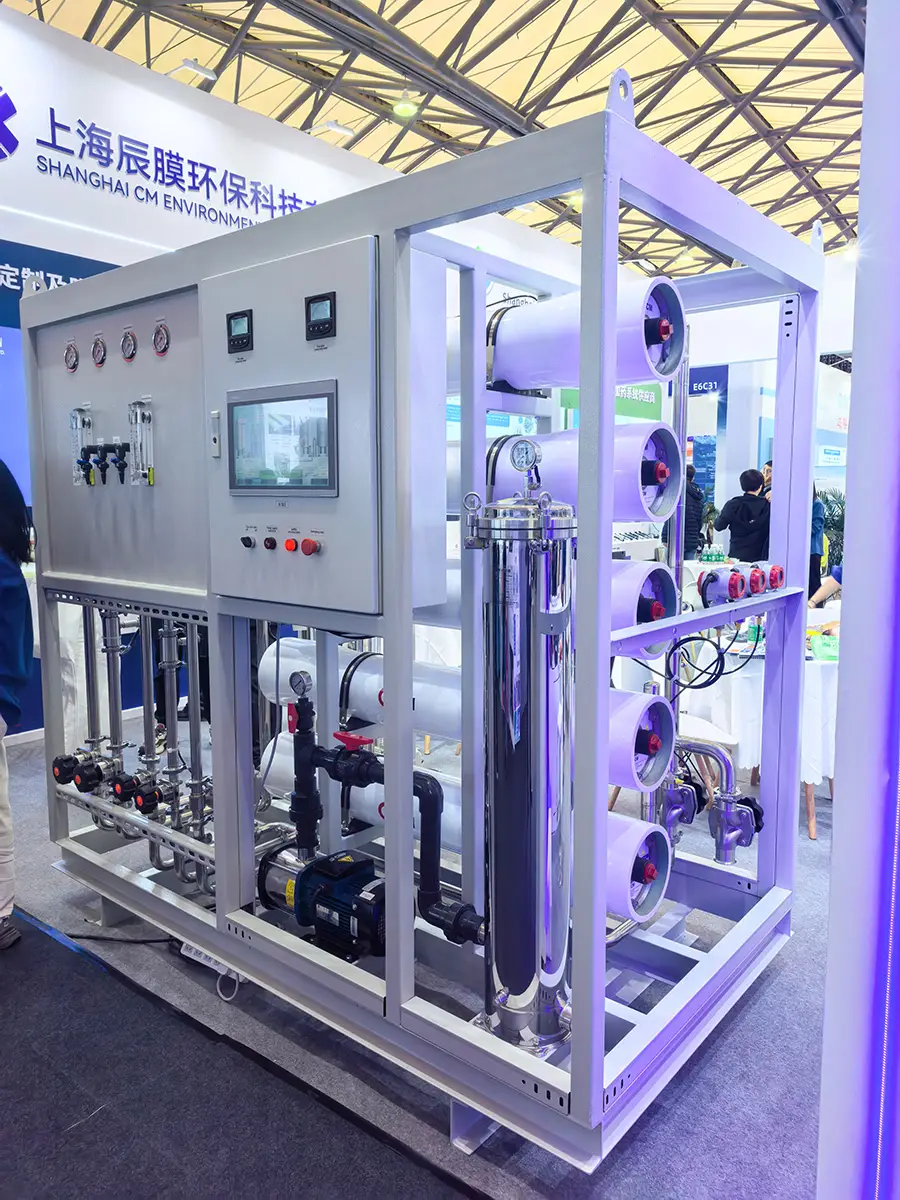

Typical Industrial RO System Configuration

A complete industrial reverse osmosis system typically consists of integrated components working in harmony to deliver optimal water treatment performance and reliability.

Pretreatment

Multimedia Filtration & Softening

High-Pressure Pump

Pressure Generation

RO Membranes

Elements & Vessels

Control System

PLC / HMI Monitoring

Pretreatment System

Multimedia filtration, softening, chemical dosing, or ultrafiltration as required

High-Pressure Pump

Provides operating pressure for membrane separation process

RO Membrane Elements

High-performance membranes in pressure vessels for water purification

Instrumentation & Monitoring

Flow, pressure, conductivity monitoring for optimal performance

PLC / HMI Control System

Automated control and user-friendly interface for system operation

CIP System

Clean-in-place system for automated membrane cleaning and maintenance

Critical Role Integration

Each component plays a critical role in protecting membranes, maintaining performance, and ensuring stable long-term operation. Our integrated approach ensures optimal system efficiency and reliability.

Industrial RO Systems

Each configuration is selected based on site conditions, future expansion plans, and operational requirements.

By System Capacity

Small Industrial RO Systems

1-5 m³/h

For pilot projects, small production lines, or decentralized water treatment.

Medium Industrial RO Systems

10-50 m³/h

Widely used in manufacturing plants and industrial utilities.

Large-Scale Industrial RO Plants

100+ m³/h

For municipal-industrial projects, power plants, and centralized water treatment.

Typical Technical Parameters of Industrial RO Systems

Industrial RO system parameters vary depending on feed water quality and project objectives. Typical design ranges include:

Note: All parameters are optimized to balance water recovery, membrane protection, and operating cost rather than pursuing maximum values.

System Design Parameters

Optimized for performance, efficiency, and reliability

| Parameter | Typical Range |

|---|---|

| System capacity | 1-500 m³/h (customized) |

| Salt rejection | ≥99.5% |

| Recovery rate | Up to 75% (optimized) |

| Feed water TDS | Customized based on analysis |

| Operating pressure | Project-specific |

| Control system | PLC with HMI |

Designed for Complex and Fluctuating Feed Water Conditions

One of the biggest risks in industrial RO projects is designing systems based on ideal water quality instead of real operating conditions.

Industrial Feed Water Often Presents Challenges Such As:

High TDS and Osmotic Pressure

Increased energy requirements and scaling risks

High Hardness and Scaling Tendency

Membrane fouling and performance degradation

Oil, Organics, or Suspended Solids

Complex pretreatment requirements

Seasonal Water Quality Fluctuations

Variable operating conditions and challenges

Handling High TDS Feed Water

High TDS water increases operating pressure and scaling risk. Industrial RO systems must be designed with appropriate membrane selection, staging configuration, and recovery control to ensure stable operation.

Reducing Membrane Fouling and Scaling

Membrane fouling is one of the most common causes of RO system failure. Proper pretreatment, optimized flux, and well-designed CIP systems are essential to minimize fouling and maintain performance.

Controlling Long-Term Operating Cost

A low initial equipment price does not guarantee a low total cost of ownership. Industrial RO system design must consider energy consumption, chemical usage, membrane replacement frequency, and maintenance workload over the system lifecycle.

Our Engineering Solution

Our industrial RO systems are engineered to operate reliably under such conditions through proper pretreatment design, conservative recovery rates, and membrane protection strategies, reducing fouling risk and extending membrane lifespan.

Customized RO System Design Based on Your Project Conditions

Industrial reverse osmosis systems are never one-size-fits-all solutions. System performance, reliability, and operating cost depend heavily on how the system is designed, not just on the equipment itself.

Our industrial RO systems are fully customized based on actual project requirements, including feed water quality, required capacity, site conditions, and long-term operational goals.

What Our Customized Design Includes

Each customized industrial RO system design is developed by our engineering team and typically includes comprehensive documentation and specifications tailored to your specific requirements.

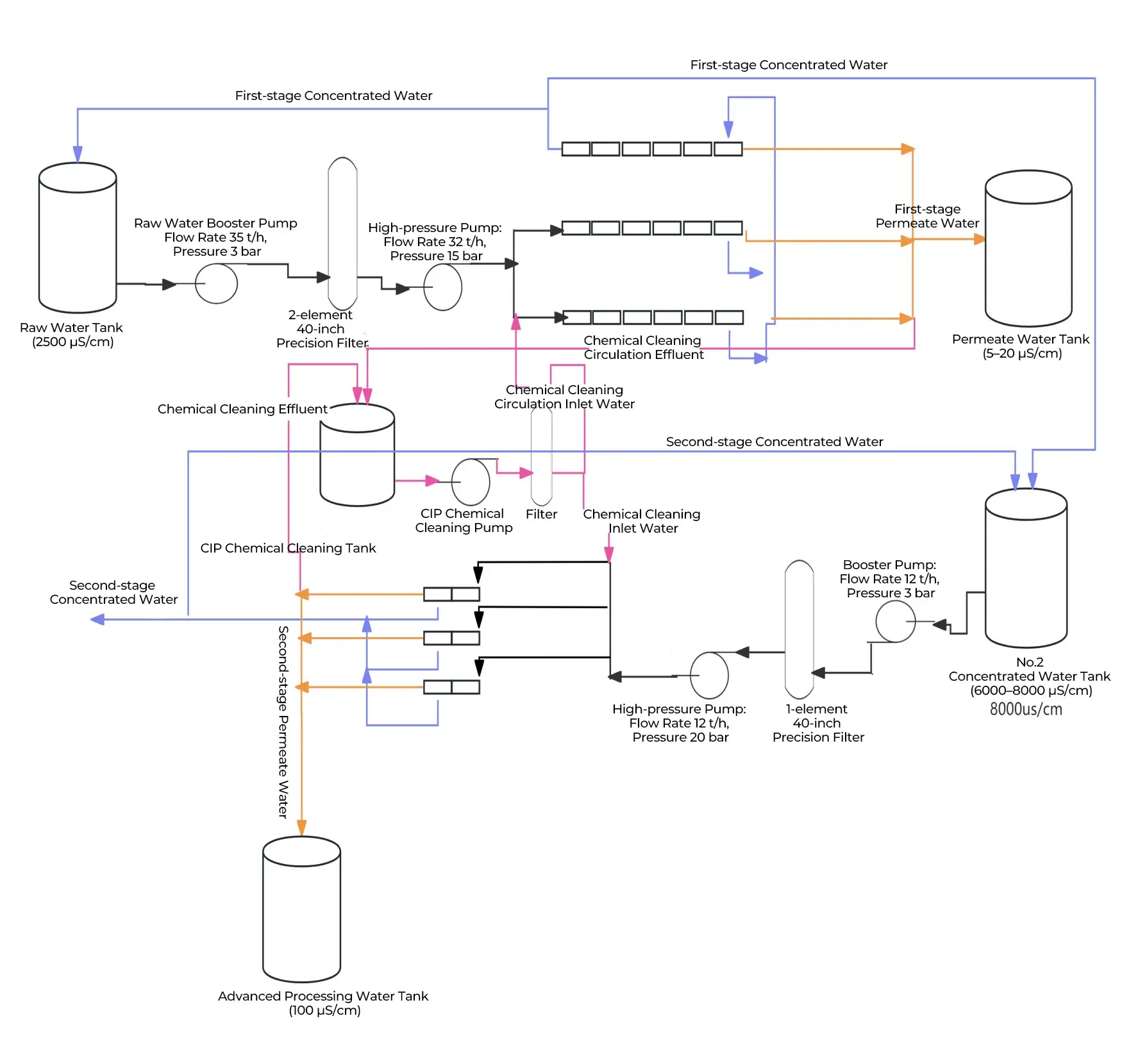

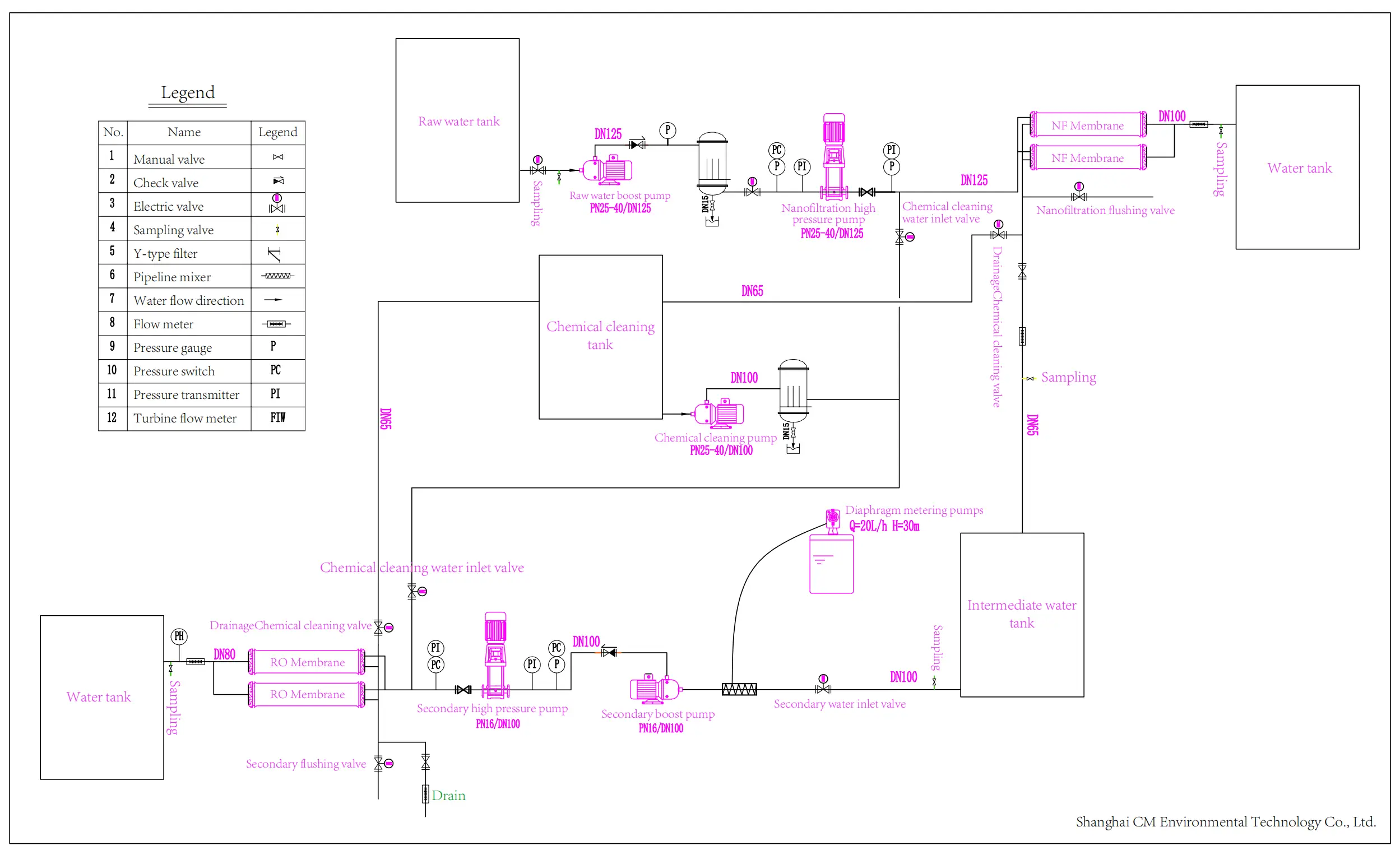

Process Flow Diagram (PFD)

Comprehensive visualization showing the complete treatment process from feed water intake to permeate production and concentrate discharge management.

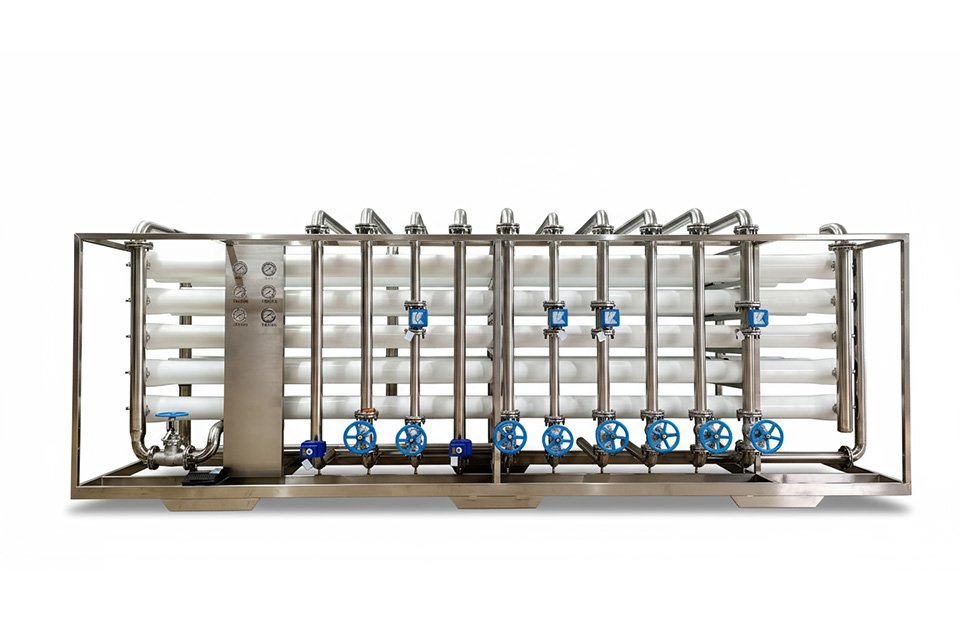

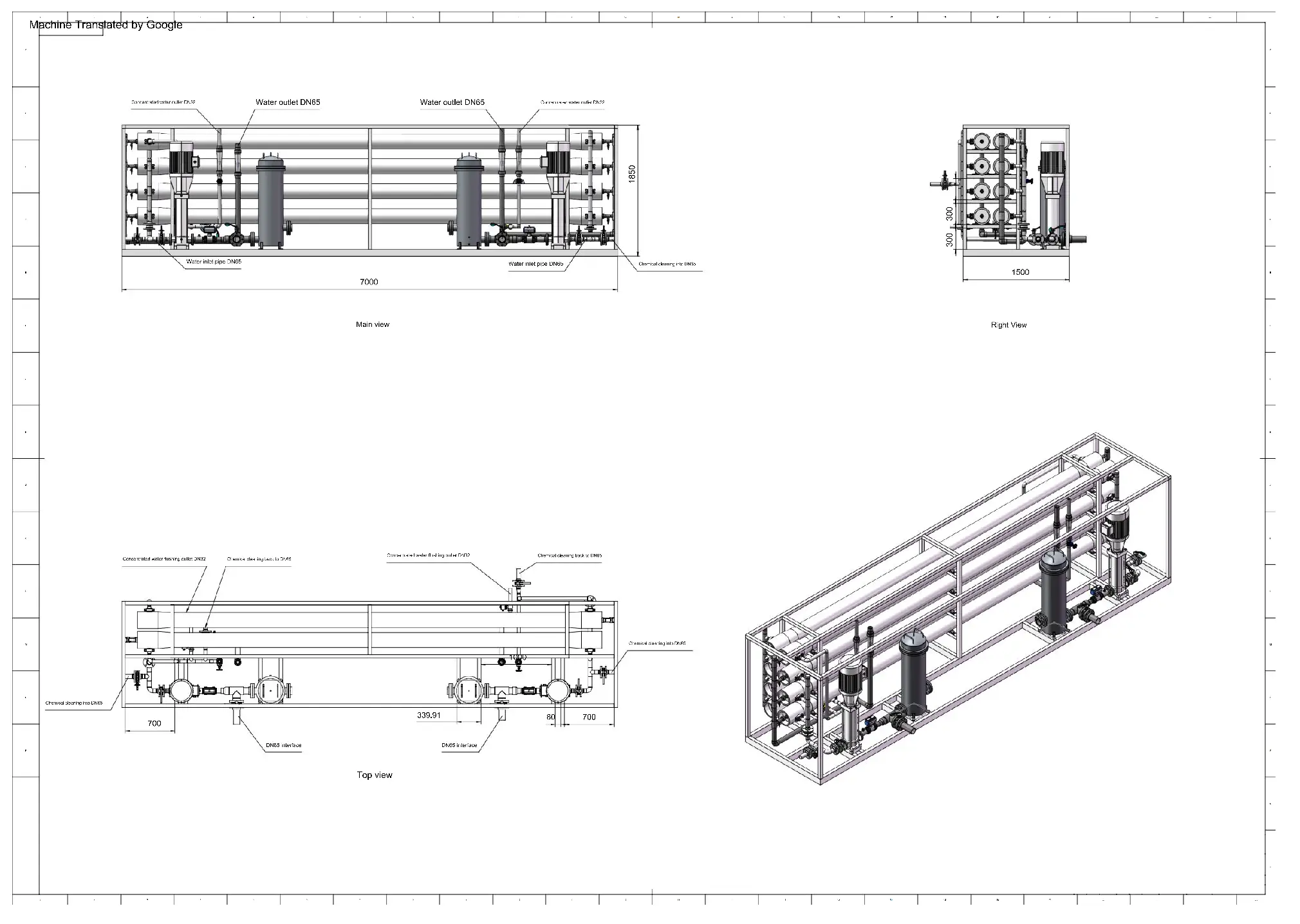

System Layout & Skid Arrangement

Optimized engineering drawings designed for efficient installation space utilization, maintenance accessibility, and future system expansion capabilities.

Equipment & Component Selection

Detailed specifications for pretreatment units, high-pressure pumps, RO membranes, instrumentation, and control systems based on performance requirements.

Design Parameters & Operating Conditions

Precise engineering calculations and operational specifications based on actual feed water analysis rather than generic industry assumptions.

Custom RO System Design

Tailored reverse osmosis systems engineered to meet specific industrial requirements with optimal efficiency and performance.

CIP Process Systems

Automated clean-in-place systems ensuring optimal membrane performance and extended equipment lifespan with minimal downtime.

Optimized System Configuration

Advanced system configurations maximizing water recovery rates while maintaining superior permeate quality for demanding applications.

Get Your Customized RO System Design

Share your project requirements with our engineering team. We'll develop a comprehensive system design tailored to your specific conditions and objectives.

Applications of Industrial Reverse Osmosis Systems

Each application has different water quality targets and operational priorities, requiring tailored system design.

Manufacturing Process Water Systems

Providing consistent water quality for production stability. Critical for industries requiring ultra-pure water for manufacturing processes.

Boiler Feed Water Treatment

Protecting boilers and reducing blowdown losses. Essential for power plants and industrial steam generation systems.

Industrial Wastewater Reuse Projects

Reducing fresh water consumption and discharge costs. Sustainable solution for water-intensive industries.

Power Plants and Energy Facilities

Supporting continuous and reliable operation. Critical infrastructure requiring uninterrupted high-quality water supply.

Why Engineering-Oriented Buyers Choose Our Industrial RO Systems

Our role is not just to supply equipment, but to reduce engineering and operational risk for our partners.

20+ Years Experience

Industrial water treatment equipment manufacturing experience with proven track record

In-house Manufacturing

Complete system design, fabrication, and testing capabilities under one roof

Project-based Customization

Custom engineering instead of standard models, tailored to specific requirements

OEM and Bulk Supply Support

Comprehensive support for EPC contractors and engineering companies

Global Project Delivery

International project experience across multiple regions and industries

Strict Quality Control

Comprehensive quality assurance and factory testing before shipment

International Trade Show Participation

We actively participate in major international water treatment and environmental technology exhibitions, where we present our industrial reverse osmosis systems and discuss real project requirements with engineers, EPC contractors, and end users from different regions.

Trade shows allow us to exchange technical insights, understand regional water challenges, and stay aligned with industry standards and market demands.

Why This Matters to Your Project

Direct Communication

with international engineering teams

Global Exposure

to diverse industrial water treatment applications

Continuous Improvement

based on real project feedback

Our presence at international exhibitions reflects our long-term commitment to the global industrial water treatment market, not just online promotion.

Our Certifications

We are proud to maintain the highest standards of quality and compliance in our industry, as evidenced by our internationally recognized certifications.

CE Certification

European UnionOur products comply with the essential requirements of relevant European health, safety, and environmental protection legislation, allowing us to trade freely within the European Economic Area.

ISO 9001 Certification

Quality ManagementOur quality management system meets the internationally recognized ISO 9001 standard, demonstrating our commitment to consistently providing products that meet customer and regulatory requirements.

SGS Certification

Global VerificationOur products have been independently verified by SGS, the world's leading inspection, verification, testing and certification company, ensuring they meet rigorous international standards.

Frequently Asked Questions About Industrial RO Systems

How does an industrial reverse osmosis system work?

Industrial RO systems use high-pressure pumps to force water through semi-permeable membranes, removing dissolved salts and contaminants. System performance depends on feed water quality, operating pressure, and pretreatment effectiveness.

How can operating cost be reduced?

Operating cost can be optimized by balancing recovery rate, energy consumption, and membrane protection rather than maximizing short-term performance.

How long do RO membranes last in industrial applications?

Membrane lifespan depends on feed water quality, pretreatment, and operating conditions. With proper design and maintenance, membranes typically last 3-5 years in industrial systems.

What feed water data is required for RO system design?

Typical data includes TDS, hardness, SDI, turbidity, temperature, and organic content. Accurate feed water analysis is essential for reliable system design.

Is maintenance complicated?

Industrial RO systems are designed for routine industrial operation. With proper training and documentation, daily operation and maintenance can be handled by on-site personnel.

Can the system be expanded in the future?

Modular and scalable designs allow capacity expansion based on future production needs, reducing reinvestment risk.

Partner with Industry Experts

Every industrial water source and application is different. Selecting the right industrial reverse osmosis system requires understanding feed water quality, operating conditions, and long-term project objectives.

Our engineering team will review your requirements and provide a solution designed for stable performance, controlled risk, and long-term value.