Seawater RO Membranes

High Salt Rejection · Anti-Fouling · Long Lifespan

Seawater desalination RO membranes empowering global water resource solutions. Solving water supply challenges for islands, coastal industries, and marine vessels while supporting sustainable water resource development.

Complete Seawater Desalination RO Membrane Series

Relying on core membrane technology, we create a diversified product matrix for different seawater qualities, treatment scales, and application scenarios, balancing efficiency and economics.

Standard Seawater Desalination RO Membrane

Core Advantages: High salt rejection (≥99.7%), stable water production flux, suitable for moderate salinity seawater treatment

High Anti-Fouling Seawater RO Membrane

Core Advantages: Special surface modification technology, anti-biofouling, anti-organic adhesion, reduced cleaning frequency, extended service life

Global Classic Application Cases

From islands to industrial bases, from municipal water supply to specialized scenarios, our seawater desalination RO membranes have served 1000+ projects globally, earning customer trust through stable performance.

Island Eco-Tourism Zone Seawater Desalination Project

Project Overview: Providing drinking water for 2000+ permanent residents and 50,000 annual tourists on an island, seawater salinity 35,000ppm, daily water production 500 tons

Selected Product: Standard seawater desalination RO membrane + pretreatment system

Project Results: Water quality meets GB5749-2022 drinking water standards, salt rejection stable above 99.8%, system continuous operation for 3 years without major failures, solving island "water shortage" problem

Coastal Chemical Park Seawater Desalination Project

Project Overview: Meeting chemical production cooling water and process water needs, daily water production 10,000 tons, raw seawater contains minor industrial pollutants

Selected Product: High anti-fouling seawater desalination RO membrane

Project Results: Product water turbidity ≤0.1NTU, meeting chemical production water requirements, membrane cleaning cycle extended to 8 months, saving 30% O&M costs vs. traditional membranes

Ocean Vessel Seawater Desalination System Retrofit

Project Overview: Providing crew domestic water for 100,000-ton ocean cargo vessel, requiring low energy consumption, compact size, and vibration resistance

Selected Product: Low pressure energy-saving seawater desalination RO membrane

Project Results: Daily water production 30 tons, operating energy consumption only 75% of traditional marine desalination equipment, adapted to marine vibration environment, stable operation for 12 months without failure

Reverse Osmosis Desalination Equipment

Professional seawater desalination systems designed for reliable freshwater production in marine environments and coastal applications.

1000L/Day RO System

Ideal for small vessels, remote locations, and emergency water supply. Compact design with high efficiency membrane technology for reliable freshwater production.

2000L/Day RO System

Perfect balance of capacity and efficiency for medium-sized operations. Advanced membrane configuration ensures consistent water quality and extended system life.

5000L/Day RO System

High-capacity solution for industrial applications and large facilities. Robust construction with redundant systems ensures continuous operation and maximum reliability.

What Our Customers Say

Every feedback drives us forward. We are committed to making excellent membranes and ensuring every customer is satisfied.

Seawater Desalination Plant Manager

Municipal Water Treatment Facility

"We use their high anti-fouling RO membranes for treating nearshore polluted seawater with excellent results. Previously with other brands, we had to clean every 3 months, now we can go up to 8 months. Stable water production and significantly reduced O&M costs - very reliable!"

Tourism Operations Director

Island Resort Management

"Water shortage has always been our pain point on the island. After installing their seawater desalination equipment and RO membranes, we completely solved the drinking water problem for tourists and residents. The water quality tastes great, tourist satisfaction has greatly improved, and we'll choose their products for future expansion."

Marine Equipment Engineer

Shipbuilding Equipment Manufacturer

"The low pressure energy-saving membrane is perfect for marine applications! Energy consumption is even lower than expected, compact size, strong installation adaptability, and extremely stable operation during ocean voyages. It has enhanced the core competitiveness of our equipment - very pleasant cooperation!"

Procurement Manager

Chemical Enterprise

"From product selection to installation and commissioning, their technical team provided full support with professional solutions. The RO membrane's salt rejection and water production efficiency both meet our production requirements. Through long-term cooperation, both product quality and service are very reliable."

Connecting Worldwide

Through Innovation

We actively participate in major water treatment exhibitions worldwide, connecting with industry leaders and showcasing our cutting-edge membrane technology solutions.

Russia

Russia

WEFTEC Russia 2024

Showcased our latest RO membrane technology and EDI equipment solutions to Russian water treatment industry professionals.

UAE

UAE

WaterTech Middle East 2024

Demonstrated advanced desalination membrane solutions and wastewater treatment systems for the Middle Eastern market.

Indonesia

Indonesia

Indo Water 2025

Presented membrane bioreactor technology and industrial water treatment solutions to Southeast Asian partners.

Brazil

Brazil

FENASAN Brazil 2024

Exhibited nanofiltration membranes and water purification systems for South American industrial applications.

China

China

WaterTech China 2025

Presented cutting-edge reverse osmosis membranes and comprehensive water treatment solutions to domestic and international clients.

Philippines

Philippines

Water Philippines 2023

Connected with Filipino water treatment companies and demonstrated our complete membrane filtration systems.

Exhibition Impact

Building global partnerships through face-to-face connections

Explore More Water Treatment Solutions

Discover additional insights and technical resources to optimize your water treatment processes and membrane performance.

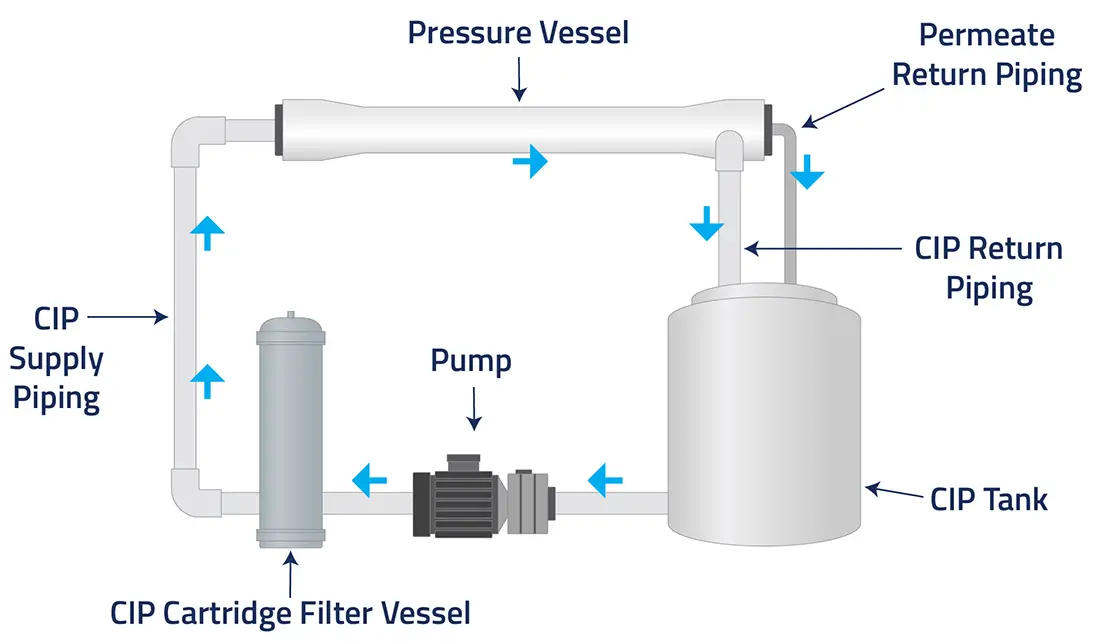

CIP Process for RO Systems: Complete Chemical Cleaning Guide

Master the Clean-in-Place (CIP) chemical cleaning process for reverse osmosis membranes. Learn optimal cleaning procedures, chemical selection, and maintenance protocols.

Common Questions & Expert Solutions

We've compiled frequently asked questions from customers. If you have other inquiries, please feel free to contact us anytime.

Can seawater desalination RO membranes maintain stable salt rejection rates?

Our seawater desalination RO membranes use high-quality membrane materials and precision manufacturing processes. Under normal operating conditions, salt rejection rates can be stably maintained at 99.5%-99.8%. We also provide targeted pretreatment solutions and operation guidance based on raw water quality, effectively preventing membrane fouling, oxidation and other issues, ensuring long-term stable salt rejection rates.

How to select RO membrane products for different salinity seawater?

For regular seawater with salinity of 30,000-35,000ppm, you can choose standard seawater desalination RO membranes. For high-salinity seawater exceeding 40,000ppm (such as Red Sea, Persian Gulf), we recommend specialty high salt rejection custom models. If seawater contains pollutants and high turbidity, prioritize high anti-fouling models to ensure membrane element service life and water production stability. Our technical team will provide precise selection solutions based on specific water quality reports.

What is the service life of seawater desalination RO membranes? How to extend it?

Under normal operating conditions, our seawater desalination RO membranes have a service life of 3-5 years. The key to extending service life lies in proper pretreatment (removing suspended solids, colloids, organics), controlling operating parameters (pressure, temperature, recovery rate), and regular standardized chemical cleaning and maintenance. We provide detailed operation and maintenance manuals for customers and have professional after-sales teams providing technical support.

Are low pressure energy-saving RO membranes significantly energy efficient? Will they affect water production efficiency?

Low pressure energy-saving RO membranes have significant energy efficiency. Operating pressure is 1-2MPa lower than standard membranes, and operating energy consumption can be reduced by 15%-20%, especially suitable for energy-sensitive scenarios (such as marine vessels, distributed desalination equipment). Meanwhile, through optimized membrane pore size and structural design, we ensure water production flux comparable to standard membranes while reducing pressure, achieving "energy saving without reducing efficiency."

Can you provide complete seawater desalination solutions, or only membrane elements?

We can provide full-chain services from "membrane element supply" to "complete solution design, equipment integration, installation and commissioning, after-sales operation and maintenance." Whether it's individual membrane element replacement or new seawater desalination projects, we can customize exclusive solutions based on customers' water production requirements, water quality conditions, site limitations, etc., ensuring efficient and stable system operation.

Get Custom Quote

Partner with industry experts for your water treatment solutions