Dealing with high-concentration wastewater is a nightmare for most plant managers. Standard filters clog instantly, costing you massive amounts of time and money. You need a solution that handles the tough stuff without failing.

DTRO (Disc Tube Reverse Osmosis) is a specialized membrane technology designed for difficult wastewater. Unlike spiral-wound membranes, DTRO uses open channels and turbulence to prevent fouling. It effectively treats leachate and high-salinity water where standard RO systems fail.

I have seen many factories struggle with standard filtration systems. They try to treat heavy wastewater, but the membranes block up in days. They spend more time cleaning the machine than running it. This kills productivity. DTRO changes this game completely. It is built differently to handle the dirtiest water. Let me show you how it works and why it might be the answer you are looking for.

How Does The DTRO Structure Prevent Clogging?

Standard membranes trap dirt like a tight net. Once they block, your production line stops. You cannot afford that downtime. You need a design that keeps water moving freely.

DTRO uses a unique stack of hydraulic discs and membrane cushions. The open flow channels create high turbulence. This turbulence stops solids from settling on the membrane surface, allowing the system to handle high pollution loads easily.

The biggest difference between DTRO and the systems you might use now is the flow path. I remember visiting a landfill site a few years ago. They tried to use standard spiral RO. It failed every week. The layers were too tight, and the sludge got stuck.

DTRO is different. We stack hydraulic discs and membrane cushions on a center rod. The feed water flows into the module and hits the bumps on the discs. This creates strong turbulence. Think of a fast-moving river hitting rocks. The water swirls and cleans the surface as it moves.

The water travels in an 'S' shape pattern. It goes over a membrane, around a disc, and back over the next membrane. The channel is wide and open. There are no dead corners for dirt to hide. Because the water moves so fast and changes direction often, contaminants cannot settle down. This self-cleaning effect is why DTRO can run for a long time without chemical cleaning.

| Feature | Standard Spiral RO | DTRO (Disc Tube RO) |

|---|---|---|

| Flow Channel | Narrow mesh spacer | Open channel disc |

| Fouling Risk | High (traps solids) | Low (self-cleaning) |

| Pre-treatment | Strict requirements | Flexible requirements |

| Pressure Limit | Low to Medium | Very High (up to 160 bar) |

When you look at this table, the choice becomes clear for dirty water. You do not need to filter every single particle before entering the DTRO. It is robust and forgiving.

What Are The Critical Parts Of A DTRO Module?

You might think complex systems are hard to fix. If a part breaks, you worry about expensive replacements. Understanding the simple parts inside DTRO removes that fear.

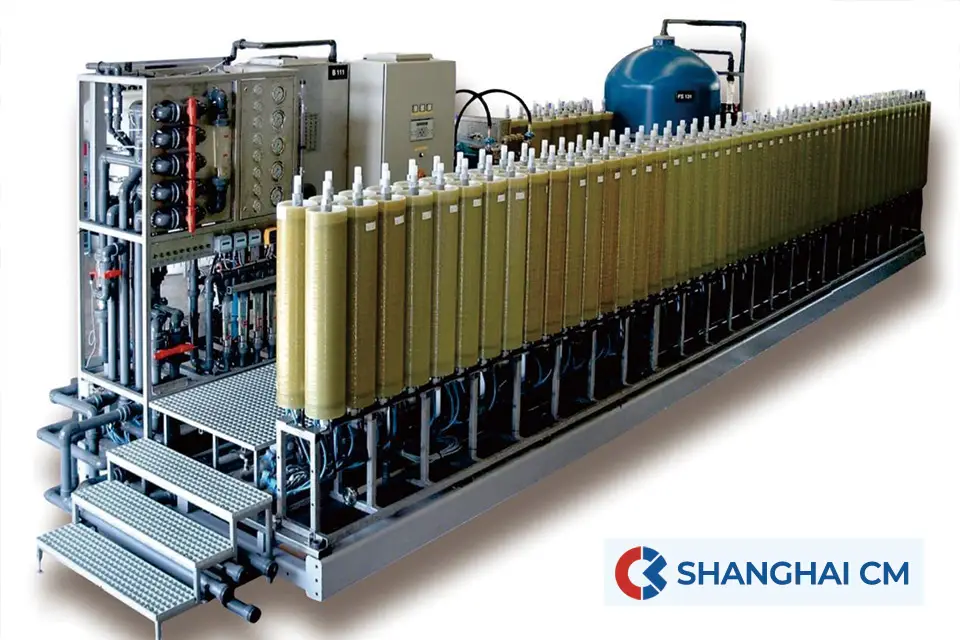

A DTRO module consists of a pressure vessel, membrane cushions, hydraulic discs, and a tension rod. The rod holds the discs and cushions together. This modular design makes cleaning and part replacement simple and cost-effective.

At Shanghai CM, I love showing clients the inside of a DTRO module. It surprises them because it is simple. It looks like a sandwich. The design is modular, which is great for maintenance.

First, you have the Membrane Cushion. This is the actual filter. It is made of two octagonal sheets welded together. Between them is a spacer. It filters the water.

Second, you have the Hydraulic Disc. This is usually made of strong plastic like ABS. It has bumps and grooves. It guides the water flow and stops the membrane cushions from touching each other.

Third, there is the Center Tension Rod. This metal rod goes through the middle. We tighten a nut at the end to compress the discs and cushions. This seals the water path.

Finally, everything goes inside a Pressure Vessel. This is a strong pipe that can handle high pressure.

Here is why this matters to you. If a standard RO element breaks, you throw the whole thing away. It is a sealed unit. With DTRO, I simply unscrew the rod. I take the discs out. I find the one bad membrane cushion. I replace that one sheet. Then I put it back together. You do not waste the good parts. This saves huge amounts of money over the life of the machine.

Component Breakdown

- Disc: Creates turbulence.

- Cushion: Does the filtering.

- Rod: Holds the seal.

- Vessel: Protects the stack.

This design also allows us to use very high pressures. We can push water through even when it is thick with salt. Standard glued membranes would burst. The mechanical stack of DTRO stays strong.

Where Can You Apply DTRO Technology Effectively?

High disposal fees hurt your profit margins. You generate dirty water and pay someone else to take it. You want to recycle that water and save cash.

DTRO is best for landfill leachate, desulfurization wastewater, and zero liquid discharge (ZLD) projects. It handles high COD and high salt content. It turns hazardous liquid waste into clean, reusable water.

You might be asking if DTRO fits your specific industry. If you have water that looks like black soup or is very salty, the answer is likely yes. At Shanghai CM, we focus on the hardest water problems.

Landfill Leachate is the most common use. When rain hits garbage, it creates a toxic liquid. It is full of organic matter and heavy metals. Standard filters die in an hour here. DTRO thrives. It separates the clean water and leaves a concentrated syrup that is easier to manage.

Zero Liquid Discharge (ZLD) is another big area. Many factories in Canada and China now cannot dump water into rivers. They must recycle everything. To do this, you need to concentrate the waste as much as possible. DTRO can reach very high pressures, up to 120 or 160 bar. This squeezes the last drops of clean water out of the brine.

We also see it in Desulfurization Wastewater. This comes from power plants. It is very corrosive and salty. The plastic discs in DTRO resist corrosion well.

I had a client recently who processes industrial chemicals. Their water had a COD (Chemical Oxygen Demand) of over 20,000 mg/L. They were paying trucks to haul it away every day. We installed a DTRO unit. Now, they reuse 80% of that water for cleaning the factory floor. The ROI (Return on Investment) took less than two years.

Key Applications List

- Garbage Dumps: Treating leachate.

- Power Plants: Flue gas cleaning water.

- Textile Mills: High dye and salt recovery.

- Military/Marine: Portable water makers for dirty sources.

If your current system requires too much chemical cleaning, or if you simply cannot filter your water because it is too dirty, DTRO is the upgrade you need. It is built for the jobs that other membranes cannot handle.

Conclusion

DTRO handles high-pollution wastewater by using open channels and turbulence to prevent clogging. It saves you money on maintenance and allows you to recycle water that other systems cannot treat.