You're designing a wastewater treatment system and wondering which technology fits your project better. The confusion between MBR and MBBR can cost you time and money if you pick the wrong approach.

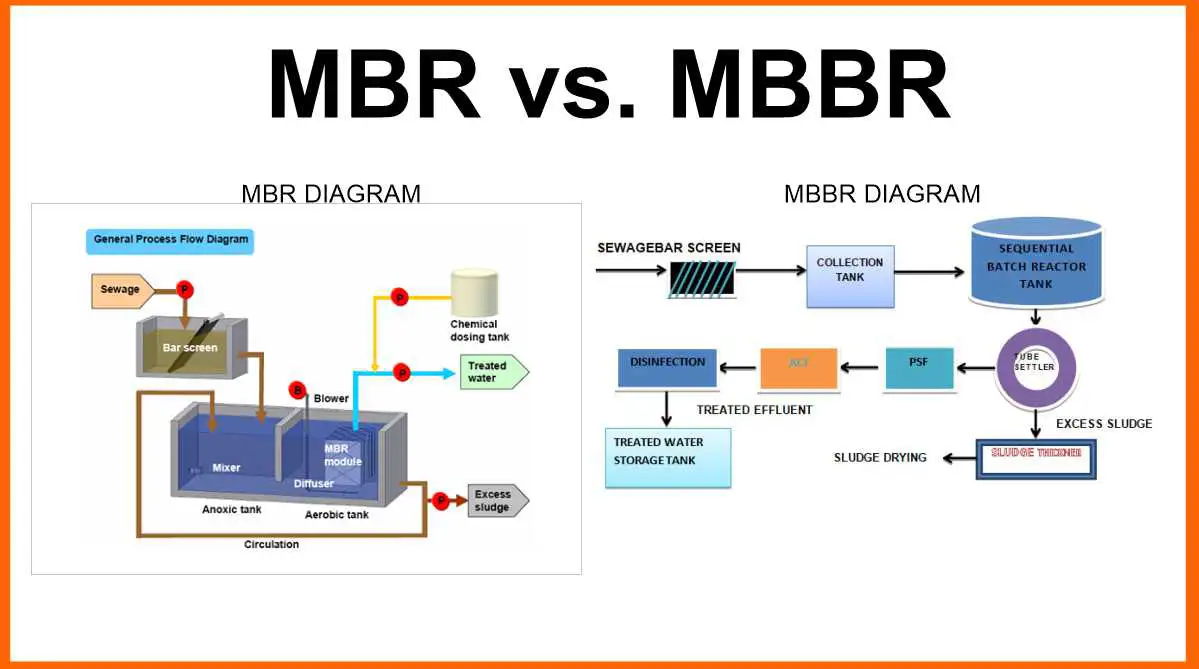

MBR (Membrane Bioreactor) combines biological treatment with membrane filtration, while MBBR (Moving Bed Biofilm Reactor) uses moving plastic carriers for biofilm growth. MBR offers superior effluent quality but requires higher energy, whereas MBBR provides robust performance with lower maintenance needs.

I've spent years working with mold manufacturers who produce components for both systems. The design requirements are completely different, and understanding these differences helped me guide my clients to better business decisions.

How does MBR technology actually work?

MBR systems look complex from the outside, but the core principle is straightforward. You're combining two proven processes into one compact unit that delivers exceptional results.

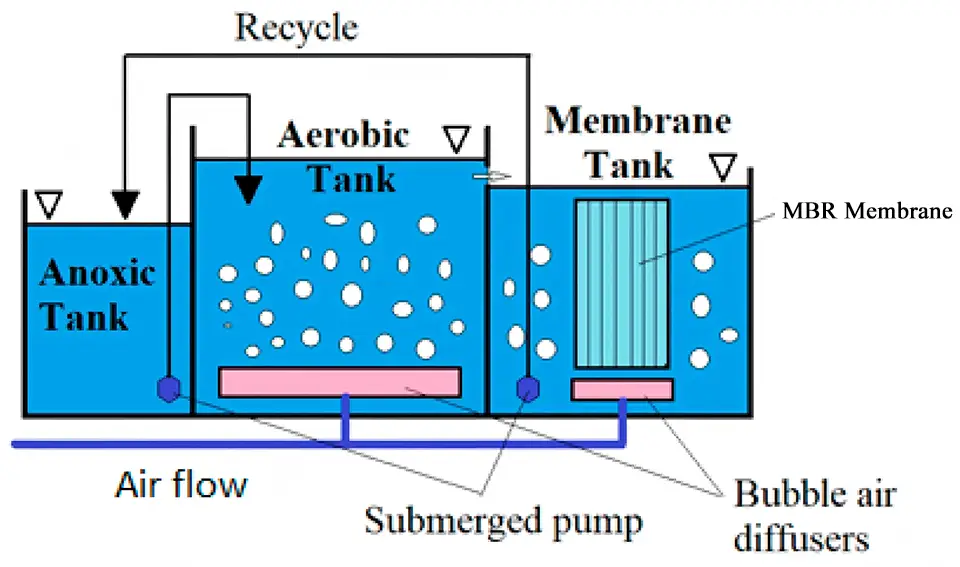

MBR integrates activated sludge treatment with ultrafiltration or microfiltration membranes. The membranes replace secondary clarifiers, providing physical separation of biomass and treated water while maintaining high mixed liquor suspended solids concentrations.

The MBR Process Breakdown

The biological treatment happens first. Microorganisms break down organic pollutants in an aerated tank, just like conventional activated sludge systems. The key difference comes next - instead of settling tanks, the mixed liquor flows through membrane modules.

These membranes have pore sizes between 0.1 to 0.4 microns. They physically block suspended solids, bacteria, and most viruses. The result is crystal-clear effluent that often meets direct discharge standards.

| MBR Component | Function | Key Benefit |

|---|---|---|

| Bioreactor | Biological treatment | High MLSS concentration |

| Membrane modules | Physical separation | Superior effluent quality |

| Aeration system | Oxygen supply + scouring | Membrane cleaning |

| Permeate pump | Water extraction | Controlled flux rates |

I remember visiting a client's facility where they switched from conventional treatment to MBR. The footprint reduction was remarkable - they freed up 60% of their treatment area. The membrane configuration allowed them to maintain biomass concentrations of 8,000-12,000 mg/L, compared to 2,000-4,000 mg/L in conventional systems.

The maintenance requirements are specific. Membrane cleaning cycles run automatically, but you need skilled technicians for replacement and system optimization. My clients who manufacture membrane housings tell me the precision requirements are extreme - even small imperfections can lead to system failures.

What makes MBBR different from other biofilm processes?

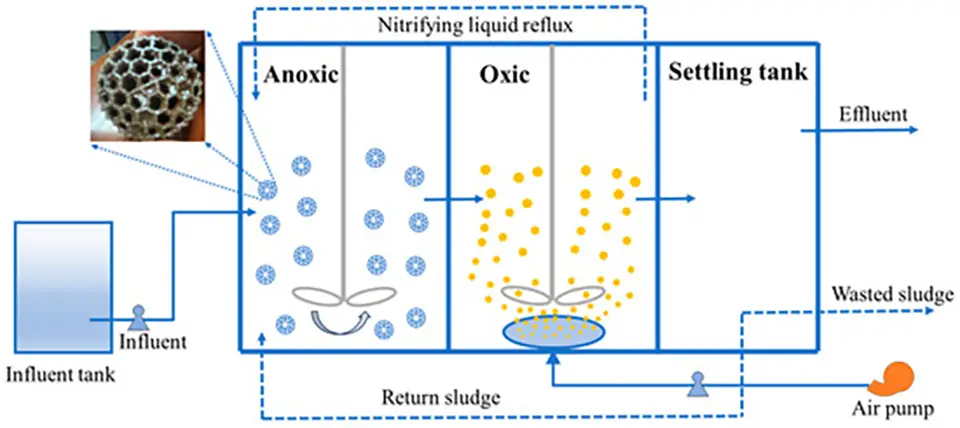

MBBR takes a completely different approach to biological treatment. Instead of relying on suspended biomass, you're creating conditions for attached growth on moving carriers throughout the reactor.

MBBR uses small plastic carriers (biocarriers) that move freely in the reactor, providing surface area for biofilm development. The carriers typically fill 40-70% of the reactor volume and create a hybrid system combining suspended growth and attached growth processes.

Understanding MBBR Carrier Design

The plastic carriers are the heart of the system. Each carrier has a specific surface area, typically 300-1200 m²/m³. The design includes internal surfaces protected from abrasion and external surfaces for oxygen transfer.

The carriers move continuously due to aeration or mechanical mixing. This movement prevents clogging, ensures good mass transfer, and maintains aerobic conditions throughout the biofilm. The biofilm thickness self-regulates through shear forces - when it gets too thick, outer layers slough off naturally.

| MBBR Parameter | Typical Range | Impact on Performance |

|---|---|---|

| Carrier fill ratio | 40-70% | Higher ratios increase treatment capacity |

| Surface area | 300-1200 m²/m³ | More surface = better treatment |

| Biofilm thickness | 50-200 microns | Optimal thickness for mass transfer |

| Mixing intensity | Low-moderate | Prevents clogging, maintains DO |

One of my clients specializes in injection molding these carriers. The material selection is critical - it needs to be durable, have the right density for movement, and provide good biofilm adhesion. We worked together to optimize the mold design for consistent wall thickness and surface texture.

The beauty of MBBR lies in its resilience. The biofilm protects microorganisms from shock loads and toxic substances. I've seen systems recover from upsets that would crash conventional activated sludge processes. The attached biomass provides stability that suspended systems simply cannot match.

Which system delivers better treatment performance?

Performance comparison depends entirely on your specific requirements and constraints. Both systems excel in different scenarios, and the choice often comes down to balancing treatment quality against operational complexity.

MBR consistently produces higher quality effluent with lower suspended solids, bacteria, and nutrients. MBBR provides robust biological treatment with excellent shock load resistance and lower energy requirements per unit of organic load removed.

Effluent Quality Comparison

MBR effluent typically achieves suspended solids below 5 mg/L, often below 1 mg/L. The membrane barrier ensures consistent quality regardless of biological variations. Pathogen removal is excellent due to physical exclusion.

MBBR produces conventional secondary treatment quality - suspended solids around 10-30 mg/L depending on downstream clarification. However, the biological treatment efficiency for BOD and COD removal often exceeds conventional systems due to higher biomass concentrations in the biofilm.

| Parameter | MBR Performance | MBBR Performance |

|---|---|---|

| Suspended Solids | <5 mg/L | 10-30 mg/L |

| BOD removal | >95% | 90-95% |

| Ammonia removal | >95% | 85-95% |

| Phosphorus removal | 80-90% | 20-40% |

| Pathogen removal | >4 log | 1-2 log |

The energy consumption tells a different story. MBR systems require 0.4-1.0 kWh/m³ for membrane operation alone, plus biological aeration. MBBR typically consumes 0.3-0.6 kWh/m³ total, with most energy going to aeration and mixing.

I worked with a facility comparing both technologies for expansion. The MBR produced reuse-quality water but doubled their energy costs. The MBBR met their discharge requirements at 40% lower operating costs. The decision came down to whether they needed the superior effluent quality to justify the additional expense.

Reliability factors matter too. MBR systems are sensitive to membrane fouling and require consistent maintenance protocols. MBBR systems are more forgiving - they handle variable loads well and continue operating even when some carriers are lost or damaged.

What are the real costs of ownership for each system?

Capital and operating costs vary significantly between MBR and MBBR systems. Understanding the total cost of ownership helps you make informed decisions that align with your long-term operational goals.

MBR systems have higher capital costs due to membrane modules and specialized equipment, but they require smaller footprints. MBBR systems cost less initially but may need larger reactor volumes and additional downstream treatment for comparable effluent quality.

Capital Cost Breakdown

MBR capital costs range from $800-2000 per m³/day capacity. Membrane modules represent 20-30% of total costs, with replacement needed every 5-8 years. The compact design often reduces civil construction costs, especially in space-constrained sites.

MBBR capital costs typically range from $400-800 per m³/day capacity. The carriers last 10-15 years, but the reactor volumes are 20-30% larger than equivalent MBR systems. Additional clarification equipment may be needed for stringent discharge requirements.

| Cost Component | MBR Range | MBBR Range |

|---|---|---|

| Base system | $600-1400/m³/day | $300-600/m³/day |

| Membrane modules | $150-300/m³/day | N/A |

| Biocarriers | N/A | $50-100/m³/day |

| Civil works | Lower (compact) | Higher (larger tanks) |

| Instrumentation | $100-200/m³/day | $50-100/m³/day |

Operating costs tell the complete story. MBR membrane replacement costs $50-100/m³/day every 5-8 years. Chemical cleaning, energy for membrane operation, and specialized maintenance add ongoing expenses. MBBR carrier replacement is infrequent, but you might need polymer addition for downstream clarification.

I helped a client evaluate both options for a 1000 m³/day facility. The MBR had 60% higher capital costs but produced water suitable for irrigation reuse. The MBBR needed additional filtration for reuse applications, which eliminated the initial savings. The decision matrix changed completely when we factored in the revenue from water sales.

When should you choose MBR over MBBR?

The choice between MBR and MBBR depends on specific project requirements, regulatory constraints, and operational priorities. Each technology has clear advantages in particular applications.

Choose MBR when you need superior effluent quality, have space constraints, or require water for reuse applications. Select MBBR for robust biological treatment, lower energy costs, or applications where operator expertise is limited.

MBR systems excel in applications requiring high-quality effluent, compact installations, and water reuse. The membrane barrier ensures consistent performance regardless of biological variations. MBBR systems work best for reliable biological treatment with minimal operator intervention and lower operating costs.