You need better treatment performance than conventional systems deliver. Both MBR and MBBR technologies promise superior results, but which one suits your specific situation?

MBR systems[^1] excel when you need the highest effluent quality and have space constraints, while MBBR works better for retrofitting existing plants and handling variable loads with lower operating costs.

I have designed and installed both technologies across dozens of projects. The choice between MBR and MBBR often comes down to your priorities: absolute treatment performance versus operational simplicity and cost control.

What Makes These Technologies Different from Conventional Systems?

Both MBR and MBBR represent major advances over conventional activated sludge treatment. They solve different problems in unique ways.

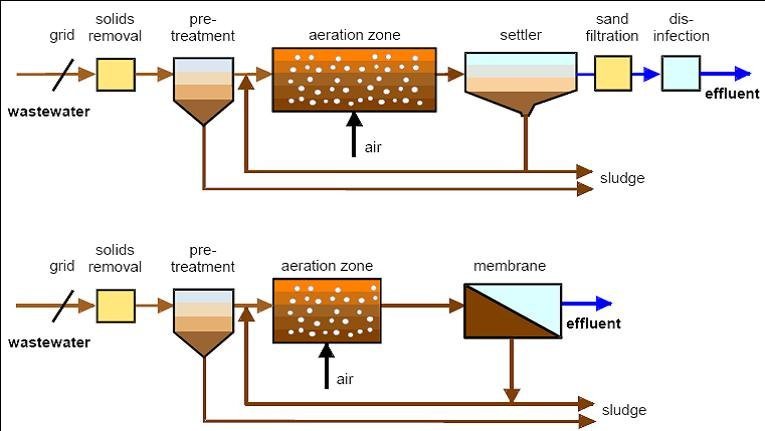

MBR uses membrane filtration to physically separate solids from treated water, while MBBR uses plastic media carriers to grow biofilm that enhances biological treatment. Both achieve better effluent quality in smaller footprints than conventional systems.

How MBR Works

MBR combines biological treatment with ultrafiltration membranes. The membranes act as a physical barrier that removes essentially all suspended solids, bacteria, and most viruses. You get consistently high-quality effluent regardless of biological process variations.

I have seen MBR plants produce effluent with less than 1 mg/L suspended solids and turbidity below 0.1 NTU even during upset conditions. The membrane barrier makes this performance predictable and reliable.

How MBBR Functions

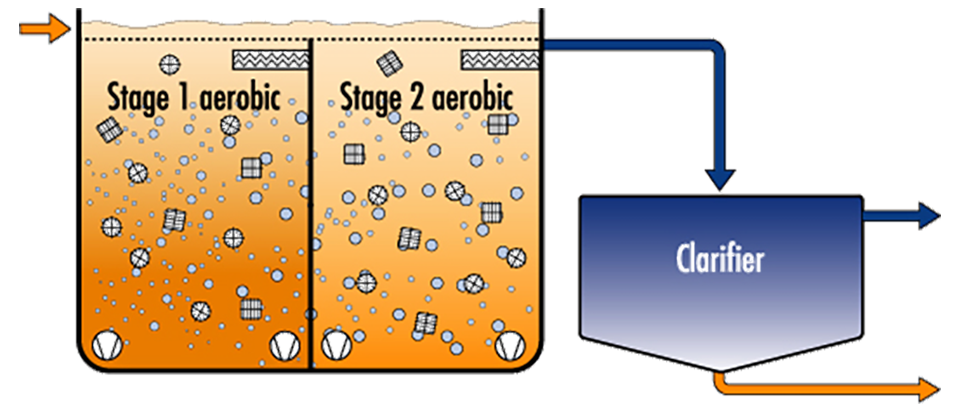

MBBR adds plastic biofilm carriers to activated sludge tanks. These carriers provide protected surface area where beneficial bacteria grow in thick biofilms. The biofilm processes nutrients and organics more efficiently than suspended growth alone.

The carriers move freely in the mixed liquor, providing oxygen transfer and preventing dead zones. This creates more stable biological treatment that handles load variations better than conventional systems.

Head-to-Head Performance Comparison

Real-world performance differences become clear when you compare key metrics across multiple projects.

MBR consistently delivers superior effluent quality but requires higher energy input and more complex operations. MBBR offers good performance improvement with simpler operations and lower energy costs.

| Performance Metric | MBR System | MBBR System | Winner |

|---|---|---|---|

| BOD Removal | >99% (1-2 mg/L) | 95-98% (2-5 mg/L) | MBR |

| TSS Removal | >99.9% (<1 mg/L) | 85-95% (5-15 mg/L) | MBR |

| Ammonia Removal | >95% (<1 mg/L) | 90-95% (1-3 mg/L) | MBR |

| Total Nitrogen | 80-90% | 70-85% | MBR |

| Pathogen Removal | 4-6 log reduction | 1-2 log reduction | MBR |

| Footprint Reduction | 50-70% vs conventional | 20-30% vs conventional | MBR |

| Energy Consumption | 0.4-0.6 kWh/m³ | 0.3-0.4 kWh/m³ | MBBR |

| Sludge Production | 30-40% less | 10-20% less | MBR |

| Operational Complexity | High | Medium | MBBR |

| Load Shock Tolerance | Medium | High | MBBR |

| Capital Cost | $800-1200/m³/day | $400-600/m³/day | MBBR |

Effluent Quality Reality Check

MBR effluent consistently meets or exceeds the most stringent discharge standards. I have never seen an MBR plant fail to meet permit limits when properly operated. The membrane barrier provides absolute reliability for suspended solids and turbidity removal.

MBBR improves conventional treatment significantly but cannot match MBR's consistent performance. MBBR effluent quality varies with biological conditions, seasonal changes, and load fluctuations.

Energy and Operating Cost Differences

MBR systems need continuous membrane aeration for fouling control. This adds 0.1-0.2 kWh/m³ to your energy consumption compared to MBBR. However, MBR eliminates secondary clarifiers and reduces pumping requirements.

MBBR requires energy for carrier mixing and aeration but uses conventional settling for solids separation. Total energy consumption stays closer to conventional activated sludge levels.

When Does MBR Make the Most Sense?

Certain project conditions strongly favor MBR technology over MBBR alternatives. I recommend MBR when specific advantages justify the higher costs.

Choose MBR when you need the highest possible effluent quality, have severe space constraints, plan direct water reuse, face extremely strict discharge limits, or want to eliminate secondary clarifiers completely.

Direct Water Reuse Projects

MBR effluent meets most reuse standards without additional treatment. This eliminates tertiary filtration, disinfection upgrades, and extensive monitoring that conventional or MBBR systems require for reuse applications.

I designed an MBR system for a manufacturing facility that reuses 80% of their treated wastewater. The MBR effluent goes directly to their cooling towers and process equipment without any polishing. This saves them $200,000 annually in municipal water purchases.

Ultra-Strict Discharge Standards

Some discharge permits require effluent quality that only MBR can reliably achieve. Limits below 2 mg/L BOD and 1 mg/L TSS push conventional and MBBR systems to their performance limits.

Severe Space Limitations

Urban installations with expensive land strongly favor MBR's compact footprint. The 50-70% space reduction compared to conventional treatment often justifies MBR's higher costs in dense urban areas.

Retrofit Complexity Issues

Existing plants with inadequate clarifier capacity benefit from MBR retrofits that eliminate clarification entirely. You can convert existing aeration tanks to MBR bioreactors and decommission failing clarifiers.

When Should You Choose MBBR Instead?

MBBR works better than MBR in specific situations where operational simplicity and cost control matter more than ultimate performance.

Select MBBR for retrofitting existing tanks, handling highly variable loads, minimizing energy costs, reducing operational complexity, or when moderate performance improvement meets your needs at lower cost.

Existing Plant Upgrades

MBBR retrofits existing aeration tanks easily by adding carriers and upgrading aeration systems. You keep existing clarifiers and avoid extensive construction. This approach costs 50-70% less than complete MBR conversion.

I retrofitted a 10 MGD plant with MBBR in just six months. We added carriers to existing tanks, upgraded blowers, and modified return sludge systems. The plant now meets new nitrogen limits without building new tanks.

Variable Load Handling

Industrial plants with feast-or-famine loading patterns stress MBR membranes and biological systems. MBBR biofilms adapt to load changes better and recover faster from shock loads or extended low-flow periods.

Food processing plants particularly benefit from MBBR's load tolerance. Seasonal production creates extreme flow and strength variations that MBBR handles more reliably than MBR.

Budget-Constrained Projects

Municipal plants with limited capital budgets often choose MBBR for its lower upfront costs and simpler operations. The performance improvement over conventional treatment justifies the investment even if it does not match MBR quality.

Maintenance Resource Limitations

Small municipalities without specialized maintenance staff find MBBR much easier to operate than MBR. MBBR requires basic activated sludge knowledge, while MBR demands membrane expertise and specialized equipment.

Your Technology Selection Decision Matrix

Use this framework to determine which technology fits your specific project requirements and constraints.

Start with your effluent quality requirements, then consider space constraints, budget limitations, operational capabilities, and future expansion needs to guide your technology selection.

Step 1: Define Your Performance Requirements

List your actual permit limits and future regulatory trends. If you need effluent suitable for direct reuse or TSS below 5 mg/L consistently, MBR becomes necessary. For moderate improvement over conventional treatment, MBBR often suffices.

Step 2: Assess Your Space Constraints

Calculate available land area and compare it to conventional system requirements. If you need more than 30% footprint reduction, MBR works better. For modest space savings, MBBR provides adequate improvement.

Step 3: Evaluate Your Budget Reality

Compare total project costs including construction, equipment, and 20-year operations. If capital costs dominate your decision, MBBR wins. When operational savings and revenue generation matter more, MBR often provides better value.

Step 4: Consider Your Operational Capabilities

Honestly assess your maintenance staff expertise and training resources. MBR requires specialized knowledge and backup support. MBBR builds on existing activated sludge experience that most operators already possess.

Step 5: Plan for Future Needs

Consider permit changes, capacity expansion, and reuse opportunities over the next 20 years. MBR provides more flexibility for future upgrades, while MBBR offers easier expansion within existing infrastructure.

Making Your Final Technology Choice

Both MBR and MBBR deliver superior performance compared to conventional treatment, but they solve different problems and suit different priorities. Your specific situation determines which technology provides better long-term value for your investment.

[^1]: Discover how MBR systems deliver superior effluent quality in confined spaces and learn design tips to optimize your plant’s performance.